| –

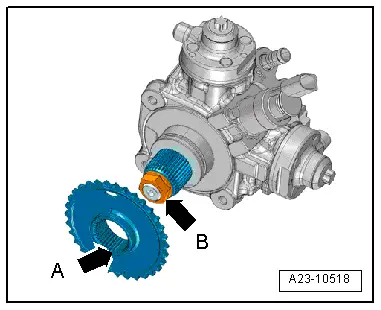

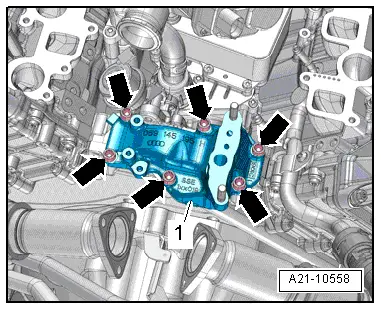

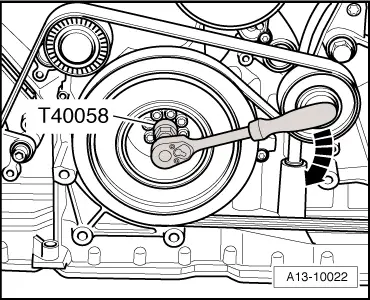

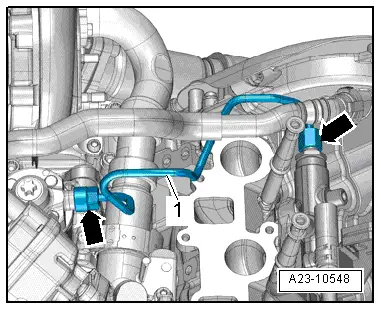

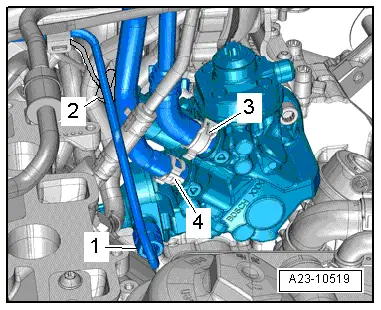

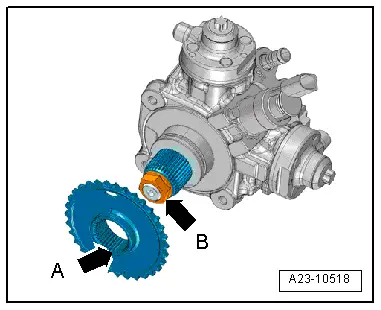

| Insert high-pressure pump into chain sprocket. |

| l

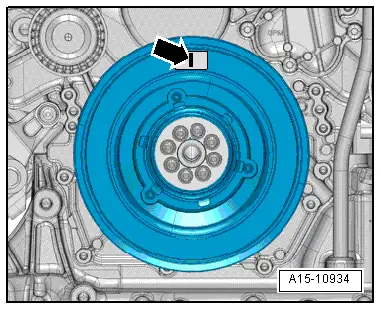

| The dual toothing -arrow A- on the chain sprocket must align with the groove -arrow B- in the adapter on the high-pressure pump shaft. |

| –

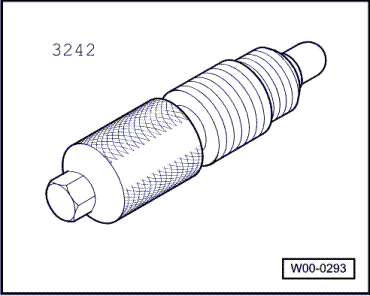

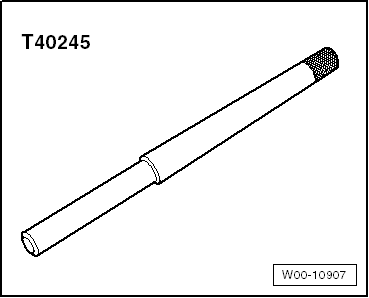

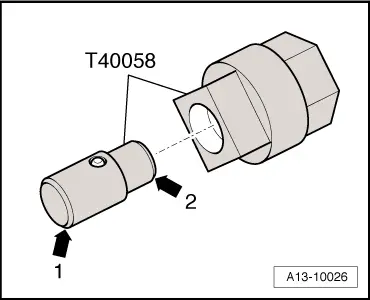

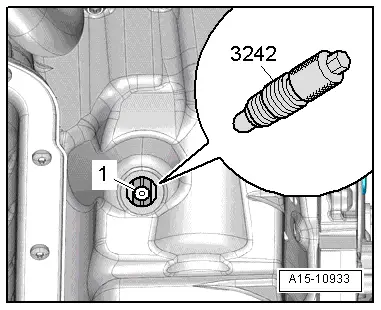

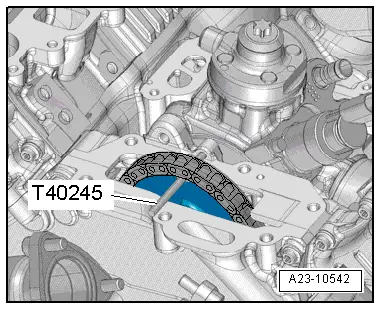

| Remove locking pin -3242- and locking pin -T40245-. |

| –

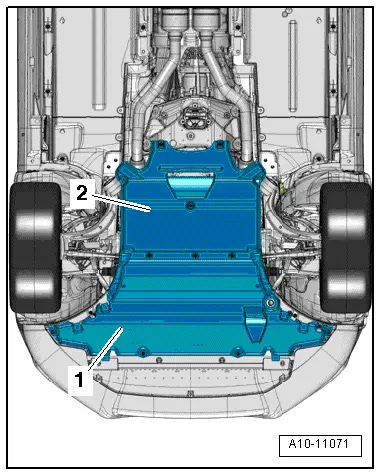

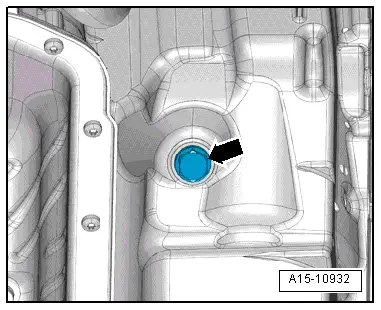

| Tighten plug for „TDC“ drilling in sump (top section) → Rep. gr.17. |

Caution | Running when dry causes irreparable damage to high-pressure pump. |

| After installing the high-pressure pump, the pump must first be filled with fuel before the engine is started for the first time → Chapter. |

|

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution