| –

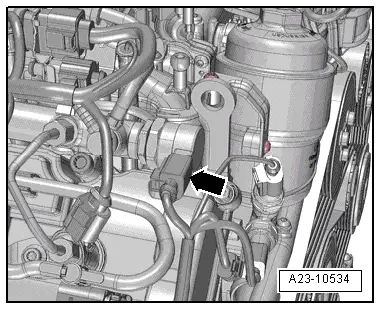

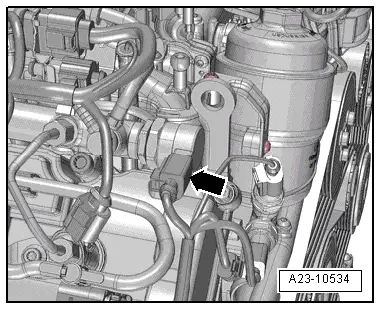

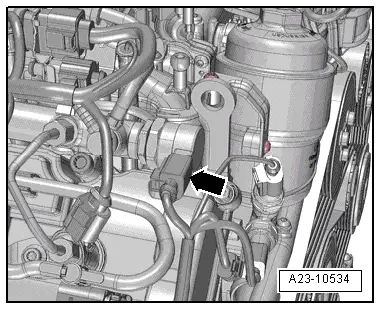

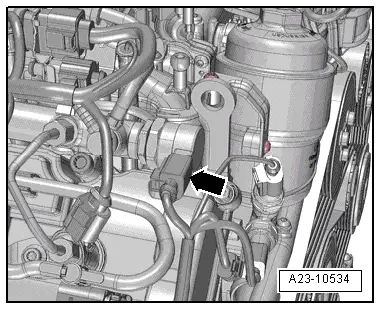

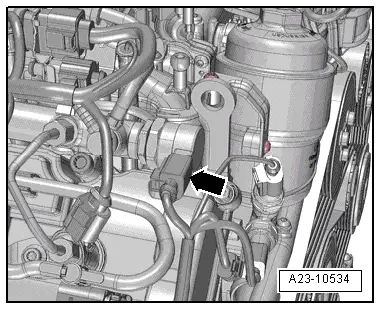

| Position fuel pressure regulating valve -N276- so that electrical wiring is not under tension when connector -arrow- is plugged in. |

| –

| Tighten union nut on regulating valve in 4 stages (counterhold hexagon flats on housing): |

| –

| Tighten banjo bolt for fuel return lines with new seals to 25 Nm. |

| Bleeding fuel system and checking for leaks |

| –

| After installation, run engine at moderate speed for several minutes and then switch off. |

Note | The fuel system is „self-bleeding“; do NOT open the high-pressure connections. |

| –

| Interrogate event memory and erase it if necessary. |

| –

| Carefully check the entire fuel system for leaks. |

| Renew affected component if leakage still occurs after tightening to correct torque. |

| After renewing high-pressure pump and/or fuel pressure regulating valve -N276-, adaption must be performed. Use → Vehicle diagnostic tester. |

| –

| After completing the repair, road-test the vehicle. Accelerate with full throttle at least once. Then check the high-pressure section of the fuel system again for leaks. |

Note | If there is any air left in the fuel system, the engine may switch to the backup mode ('emergency running' mode) during the road test. Switch off the engine and erase the event memory. Then continue the road test. |

| –

| After road test, interrogate event memory again. |

|

|

|

Note

Note Note

Note Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note Note

Note Note

Note

Note

Note Note

Note