| t

| when the vehicle is driven very fast around tight corners |

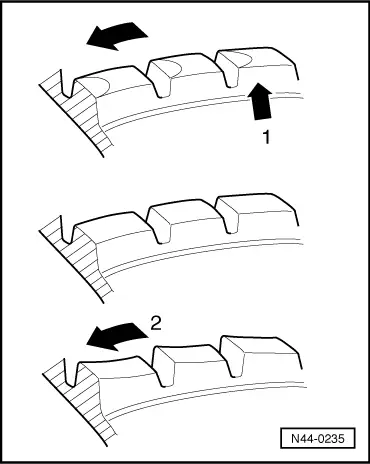

| 1 - | More pronounced wear at the front of the tread block |

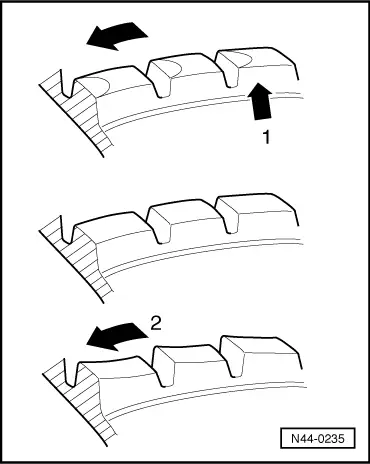

| 2 - | Direction of rotation |

| In the event of saw-tooth wear, the direction of rotation of the tyre must be reversed. If saw-tooth wear is especially pronounced and tyre noise has increased, interchange the tyres diagonally. This will reduce the saw-tooth effect. On front-wheel-drive vehicles, this effect is intensified by the greater wear on the front axle. Tyre noise will be somewhat greater immediately after the tyres have been interchanged, but will return to the normal level after driving about 500 – 1,000 km. |

| In the event of increased saw-tooth wear on the rear tyres – in particular on front-wheel-drive vehicles – interchange the front and rear tyres. In the event of increased saw-tooth wear on the outer edges of the tyres on one axle, turn both tyres around on their rims. The left-hand wheel must then be fitted on the right side of the vehicle and the right-hand wheel on the left side. |

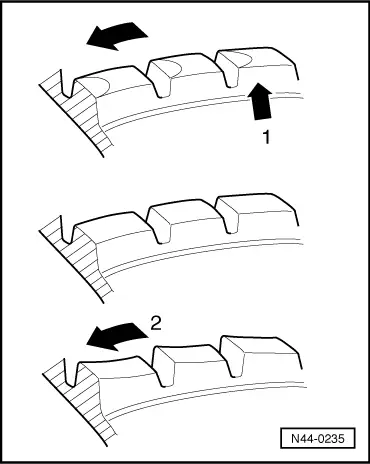

| Saw-tooth wear is a normal wear pattern and can be rectified on non-directional tyres by rotating the wheels diagonally. The wear should then be compensated after approx. 500 – 1,000 km. |

| The complaint report should include information detailing the previous repair work. |

| Modern tyres are designed for maximum driving safety, even in wet conditions. This demands an open tread pattern at the shoulders of the tyre and a softer rubber composition for the tread itself, both of which accelerate saw-tooth wear. |

| Saw-tooth wear is a normal wear pattern and does not constitute a fault which is covered by the warranty. |

|

|

|