6 Series M6 (S85) Coupe

41 00 ...

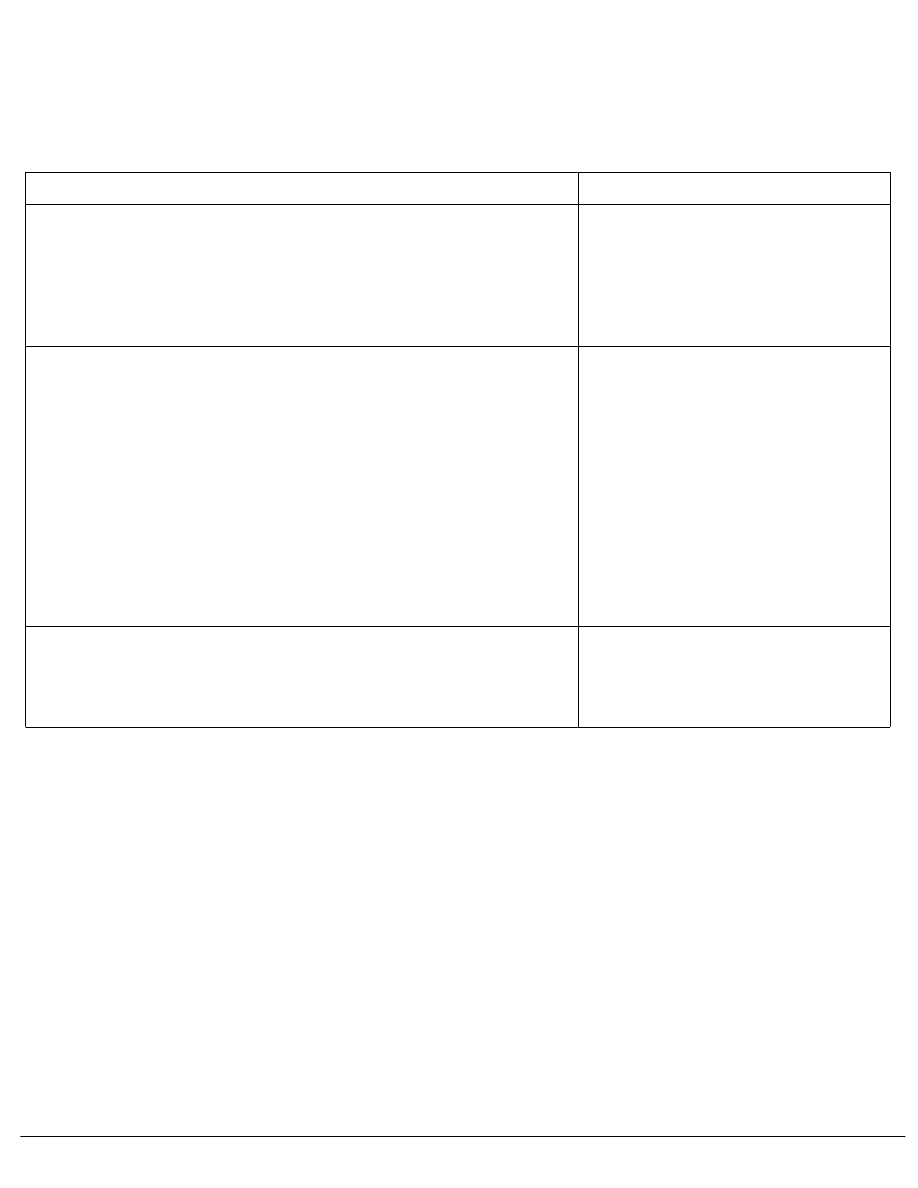

Information on hazards

1.0 Aluminum

Hazards / effects

Measures / regulations

Repair stage 1:

(replacement of bolted parts, dent removal)

Repair stage 2:

(structural repairs with bonding and riveting)

-

When a vehicle outer shell is

ground, aluminum dust

accumulates in small amounts. This

dust can be removed with

conventional extractor systems.

Repair stage 3:

(structural repairs with welding)

-

Explosion hazard due to high concentration of fine aluminum dust.

Arising e.g. during straight-through grinding of coated parts in the

base material and large-surface grinding of bright-finish parts.

-

Explosion hazard due to swirling up of fine aluminum dust in cavities.

Created by the necessary, thorough cleaning of machining surfaces

and tools before and after machining aluminum.

-

Avoid high concentration of fine

aluminum dust by means of

continuous extraction.

-

Use explosion-proof extractor

systems.

-

Do not use compressed air when

cleaning the work bay.

-

Avoid swirling up dust when

cleaning the work area.

-

Spontaneous combustion of fine aluminum dust when ignition and

fire sources are drawn in.

E.g.: hot splinters, grinding sparks, cigarettes etc.

-

Do not operate ignition and fire

sources in the intake area of

extractor systems.

RA Information on hazards

BMW AG - TIS

19.01.2013 16:01

Issue status (12/2007) Valid only until next DVD is issued

Copyright

Page - 1 -