Beretta L4-134 2.2L (1990)

Drive Belt: Service Precautions

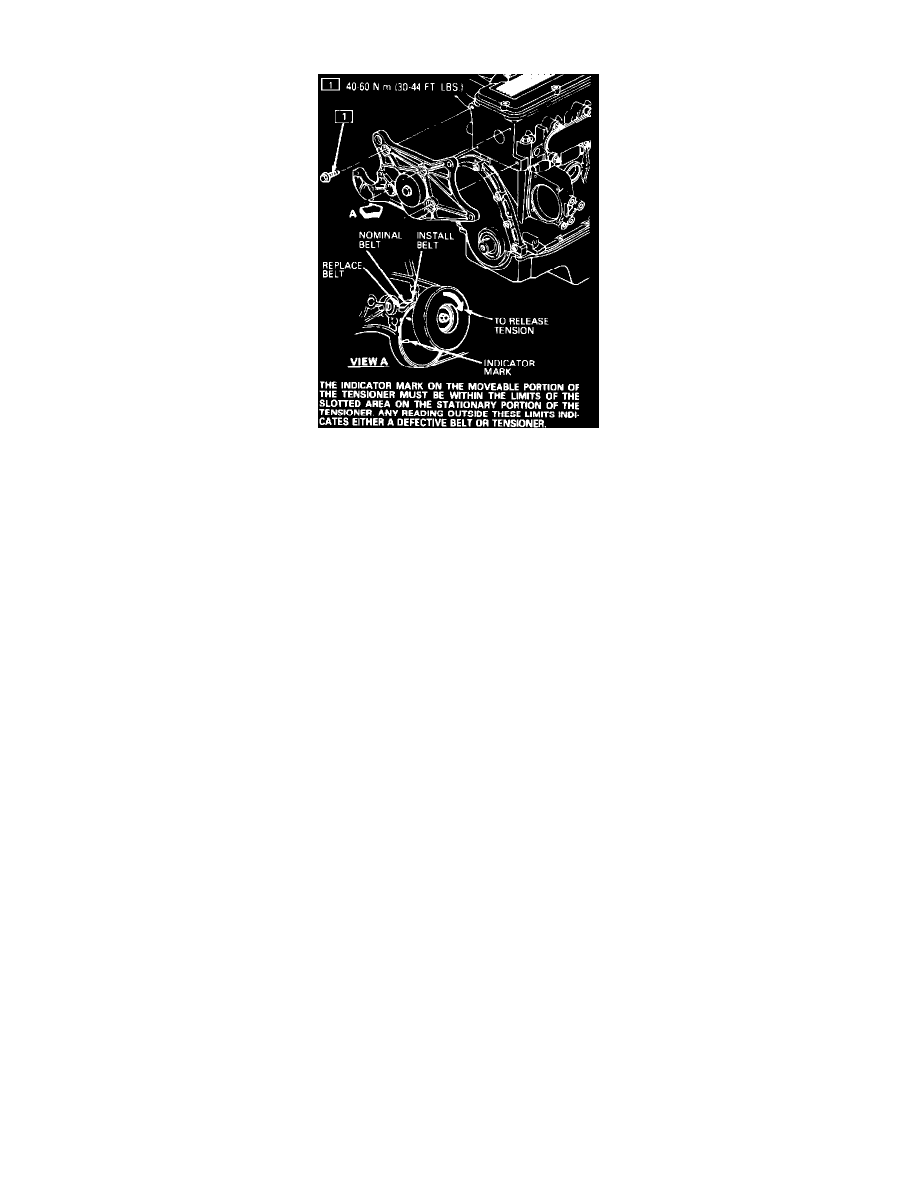

Fig. 14 Drive Belt Tensioner Assembly

When installing or removing the drive belt, never exceed 30 ft. lbs. torque on the tensioner center bolt, Fig. 14. Care should also be taken to avoid

bending or twisting the tensioner. If the belt tensioner or idler assembly produces a whining noise, inspect for bearing failure. If the drive belt becomes

frayed, check belt tensioner assembly alignment and ensure belt edge does not contact the tensioner pulley flange.

Serpentine drive belt performance will not be impaired by cracks in the belt ribs. However belt replacement will be required if any of the following

conditions occur: Belt ribs are missing, the belt slips or is frayed, or the belt tensioner runs out of travel before adjustment is proper.