Camaro V8-6.2L (2010)

*

Sumitomo Connectors (See: Testing and Inspection/Component Tests and General Diagnostics/General Electrical Diagnostic

Procedures/Connector Repairs/Sumitomo Connectors)

*

Tyco/AMP Connectors (See: Testing and Inspection/Component Tests and General Diagnostics/General Electrical Diagnostic

Procedures/Connector Repairs/Tyco/AMP Connectors)

*

Yazaki Connectors (See: Testing and Inspection/Component Tests and General Diagnostics/General Electrical Diagnostic Procedures/Connector

Repairs/Yazaki Connectors)

*

Repairing Connector Terminals (See: Testing and Inspection/Component Tests and General Diagnostics/General Electrical Diagnostic

Procedures/Connector Repairs/Repairing Connector Terminals)

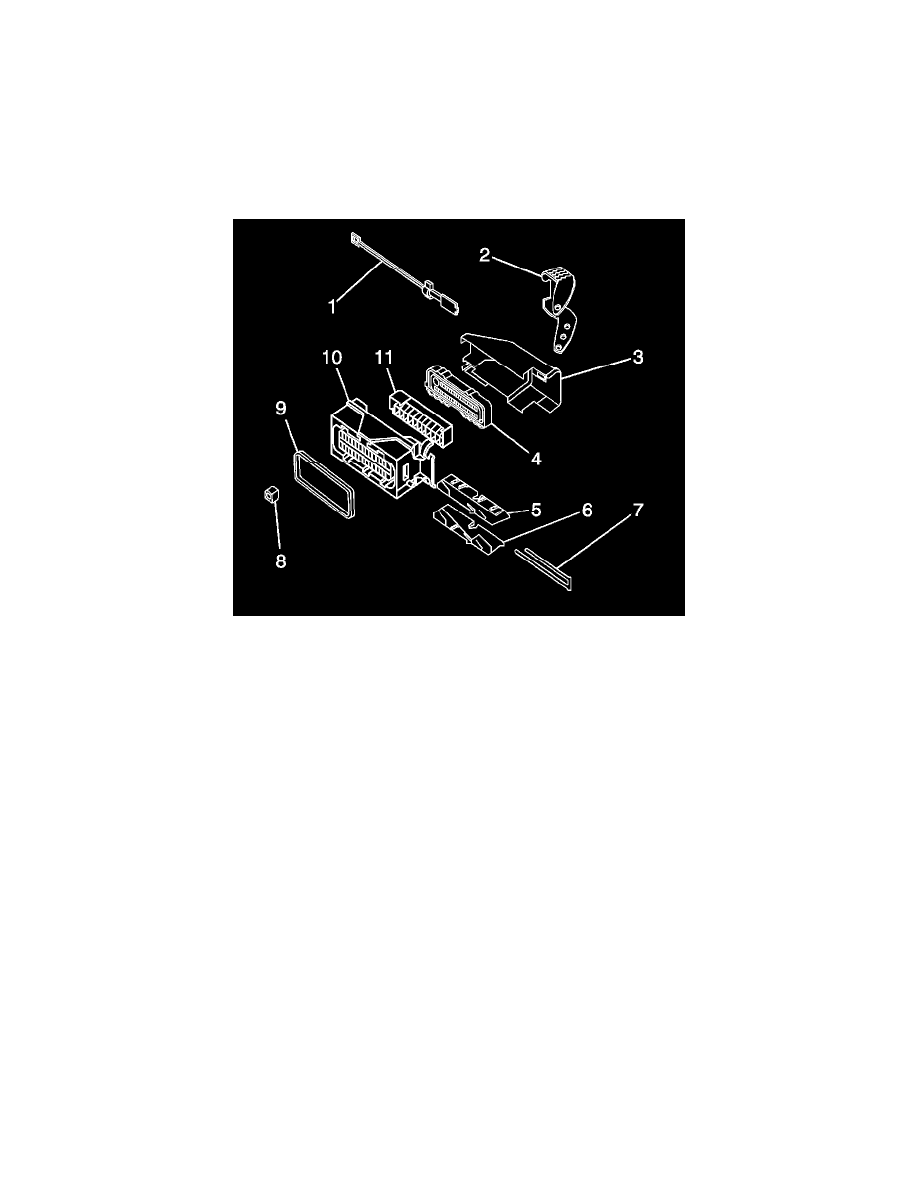

Connector Anatomy

1 - Connector Positive Assurance (CPA)

2 - Assist Lever

3 - Wiredress Cover

4 - Seal Strain/Relief

5 - Slide Left Hand

6 - Slide Right Hand

7 - Terminal Positive Assurance (TPA)

8 - Terminal Positive Assurance (TPA)

9 - Connector Seal

10 - Connector Housing

11 - Inner Connector

Identifying Connectors

Knowing the connector manufacturer is helpful when trying to locating the correct connector repair procedure. There are many different connector

designs used on GM vehicles and it is sometimes difficult to identify the connector manufacturer. The information in this document should help with the

identification of connector manufactures.

The following connector manufacturers make most of the connectors found in GM vehicles:

*

AFL/EPC (Alcoa Fujikura Ltd./Engineered Plastics Components)

*

Bosch

*

Delphi

*

FCI (Framatome Connectors International)

*

JAE (Japan Aviation Electronics)

*

JST (Japan Solderless Terminals)

*

Kostel

*

Molex

*

Sumitomo

*

Tyco/AMP