Concorde V6-3.5L VIN V (2003)

Steering Gear: Description and Operation

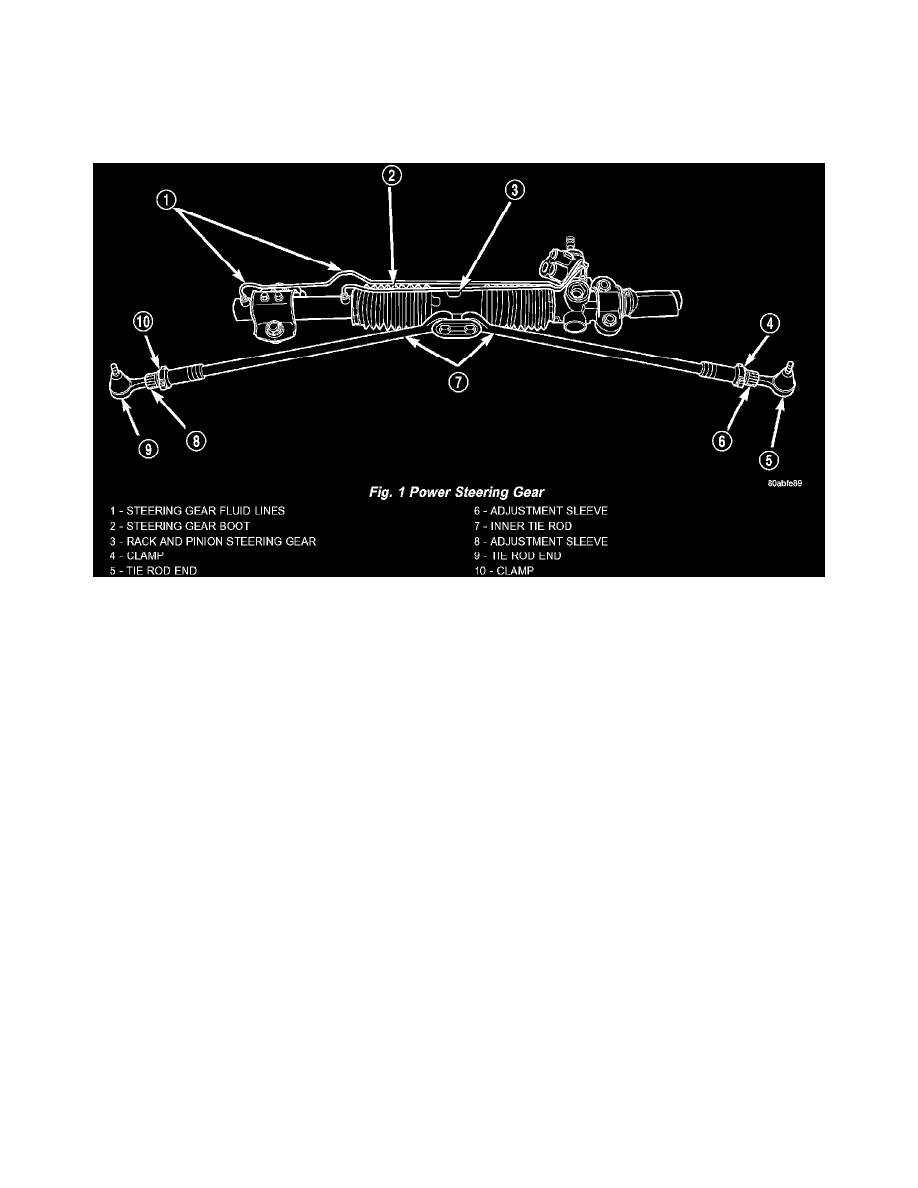

Power Steering Gear

Description

DESCRIPTION - POWER STEERING GEAR

This vehicle is equipped with a rack-and-pinion power steering gear. The gear is a center take-off type gear. Center-take-off means that the tie rods are

connected to the steering gear via a rack guide located at the center of the gear.

The power steering gear is mounted on the crossmember behind the engine. The steering column intermediate shaft connects to the pinion shaft of the

gear. The outer ends of the outer tie rods attach to steering arms on the suspension's front struts.

Three different power steering gears are available:

-

A base gear

-

A firm feel gear, and

-

A speed proportional gear

The base gear and firm feel gear are serviced the same. The speed proportional steering gear is physically very similar to the standard gear except for

the solenoid control valve extending from its housing. The solenoid control valve can be serviced separately. For information on the speed

proportional power steering gear or its individual components, refer to Speed Proportional Steering Gear.

NOTE: The power steering gear should not be serviced or adjusted. If a malfunction or oil leak occurs, the complete steering gear needs to be

replaced.

Operation

OPERATION

OPERATION - POWER STEERING GEAR

Turning of the steering wheel is converted into lateral (side-to side) travel through the meshing of the helical pinion teeth with the rack teeth located in

the steering gear. This lateral travel pushes and pulls the tie rods to change the direction of the vehicle's front wheels.

Power assist is provided by a pump and is controlled by an open-center, rotary type control valve. It directs fluid to either side of the gear's integral

steering rack piston. Depending on the rotation of the steering wheel, more fluid pressure is directed to one side of the rack piston compared to the

other.

Road feel is controlled by the diameter of a torsion bar, which initially steers the vehicle. As steering effort increases, as in a turn, the torsion bar

twists causing relative rotary motion between the rotary valve body and valve spool. This movement restricts fluid flow to one side of the integral rack

piston and redirects fluid behind the other side of the integral rack piston, building up hydraulic pressure, thus assisting in the turning effort.