Pacifica V6-3.8L VIN L (2005)

Connecting Rod Bearing: Service and Repair

Connecting Rod and Bearing Fitting

STANDARD PROCEDURE - FITTING CONNECTING RODS

The bearing caps are not interchangeable or reversible, and should be marked at removal to ensure correct reassembly. Forged bearing caps stay with

forged rods, cracked bearing caps stay with the forged cracked rod. The bearing shells must be installed with the tangs inserted into the machined

grooves in the rods and caps. Install cap with the tangs on the same side as the rod. For connecting rod bearing fitting Refer to CONNECTING ROD

BEARINGS - STANDARD PROCEDURE. Fit all connecting rods on one bank until complete.

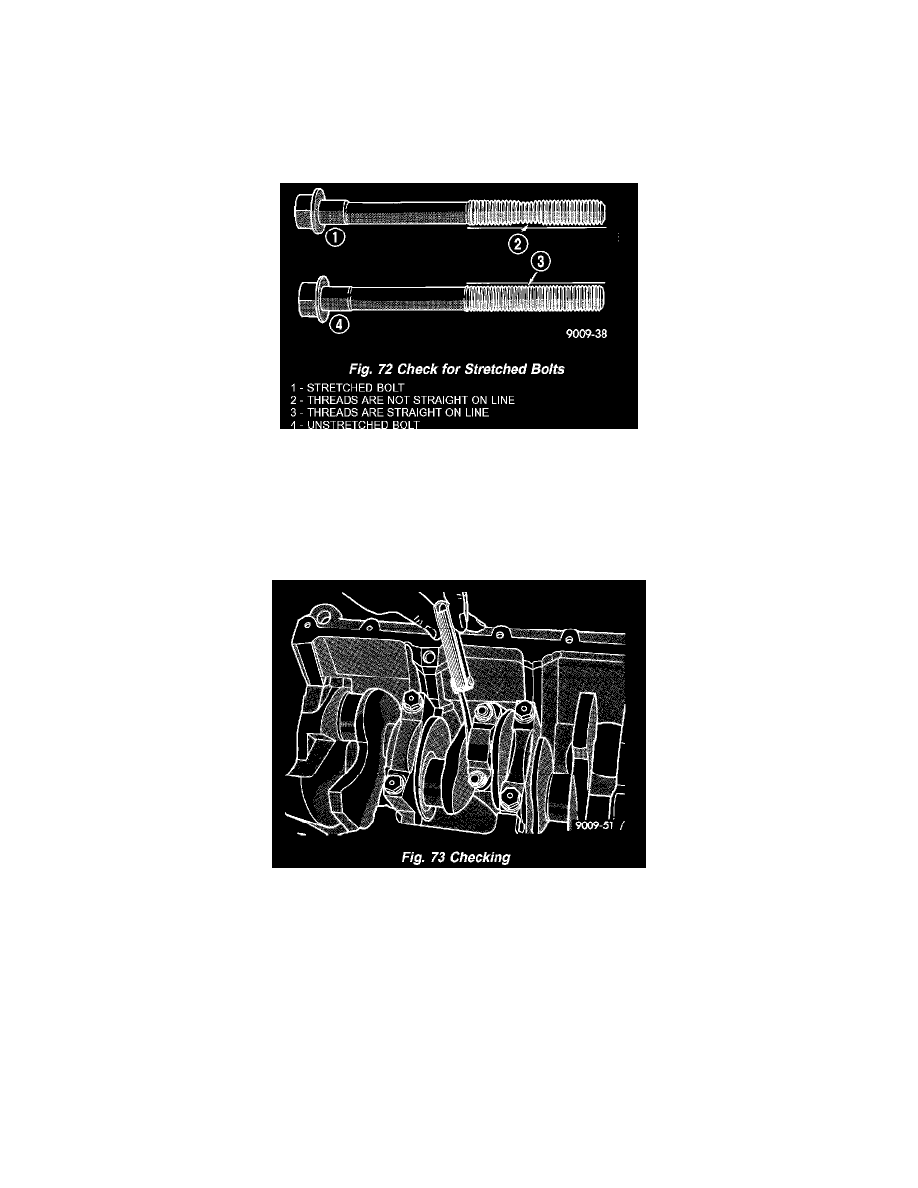

NOTE: The connecting rod cap bolts should be examined before reuse. Bolt stretch can be checked by holding a scale or straight edge against the

threads. If all the threads do not contact the scale the bolt must be replaced (Fig. 72).

1) Before installing the nuts or the bolts the threads should be oiled with engine oil.

2) Install nuts or bolts finger tight then alternately torque each nut or bolt to assemble the cap properly.

3) Tighten the nuts to 54 Nm PLUS 1/4 turn (40 ft. lbs. PLUS 1/4 turn).

4) Tighten the cracked cap bolts to 28 Nm PLUS 90 degrees (20 ft. lbs.) plus 90 degrees.

5) Using a feeler gauge, check connecting rod side clearance (Fig. 73). Refer to Engine Specifications.