2500 4x2 Pickup L6-359 5.9L DSL Turbo (1994)

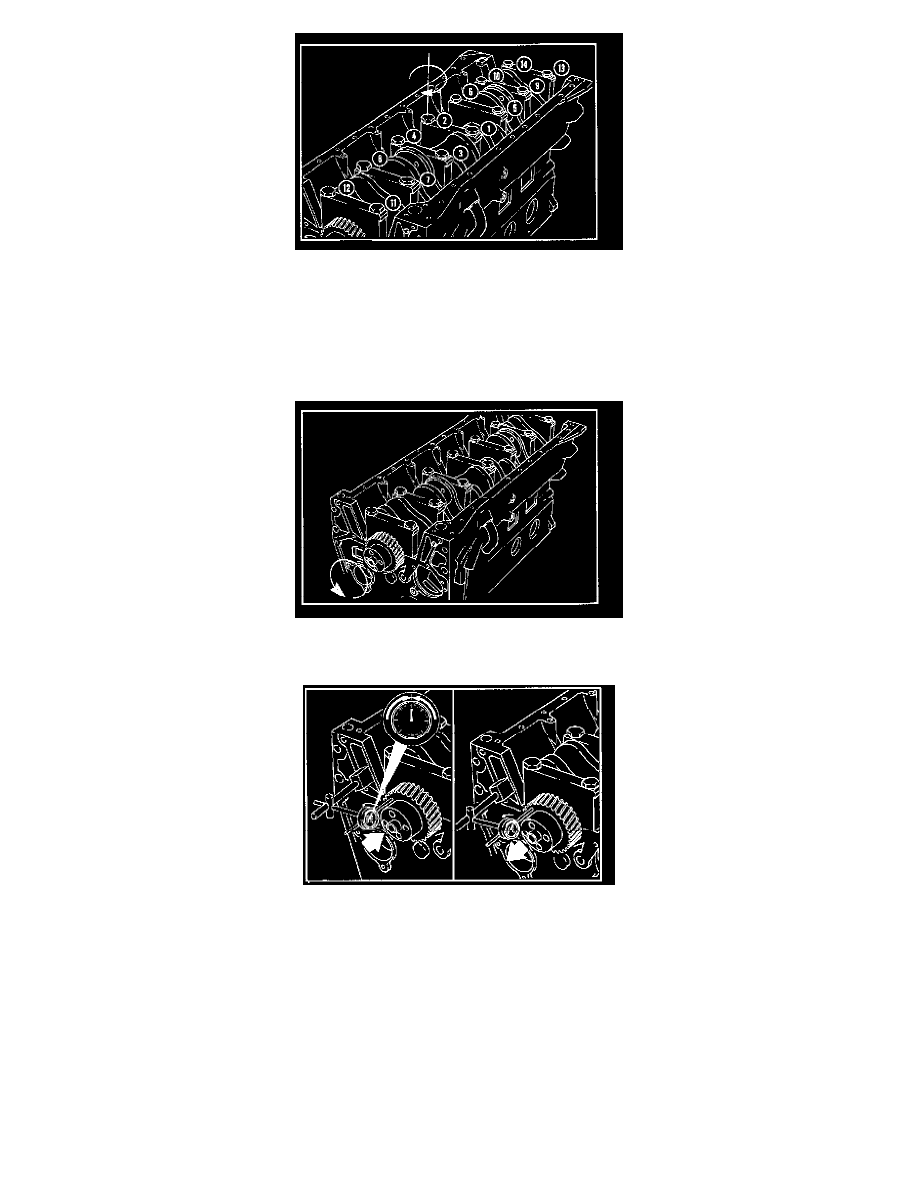

Tighten the capscrews evenly in the sequence shown using the following torque steps.

Step Torque Value

1

60 N-m [45 ft-lbs]

2

119 N-m [88 ft-lbs]

3

176 N-m [129 ft-lbs]

Turn the crankshaft to determine that it will rotate freely all 360 degrees. Check the main bearing cap installations and/or the bearing sizes if the

shaft does not turn easily.

Push the crankshaft towards one end of its thrust and place a dial Indicator as shown. Zero the indicator needle and push the crankshaft towards the

other end of its thrust and record the indicator reading.