F 350 2WD Super Duty V8-5.4L (2008)

Variable Valve Timing Actuator: Description and Operation

VARIABLE CAMSHAFT TIMING (VCT) SYSTEM

Overview

The VCT enables rotation of the camshaft(s) relative to the crankshaft rotation as a function of engine operating conditions. There are 4 types of VCT

systems.

-

Exhaust phase shifting (EPS) system - the exhaust cam is the active cam being retarded.

-

Intake phase shifting (IPS) system - the intake cam is the active cam being advanced.

-

Dual equal phase shifting (DEPS) system - both intake and exhaust cams are phase shifted and equally advanced or retarded.

-

Dual independent phase shifting (DIPS) system - where both the intake and exhaust cams are shifted independently.

All systems have 4 operational modes: idle, part throttle, wide open throttle (WOT), and default mode. At idle and low engine speeds with closed

throttle, the powertrain control module (PCM) determines the phase angle based on air flow, engine oil temperature and engine coolant temperature.

At part and wide open throttle the PCM determines the phase angle based on engine RPM, load, and throttle position. VCT systems provide reduced

emissions and enhanced engine power, fuel economy and idle quality. IPS systems also have the added benefit of improved torque. In addition, some

VCT system applications can eliminate the need for an external exhaust gas recirculation (EGR) system. The elimination of the EGR system is

accomplished by controlling the overlap time between the intake valve opening and exhaust valve closing. Currently, both the IPS and DEPS systems

are used.

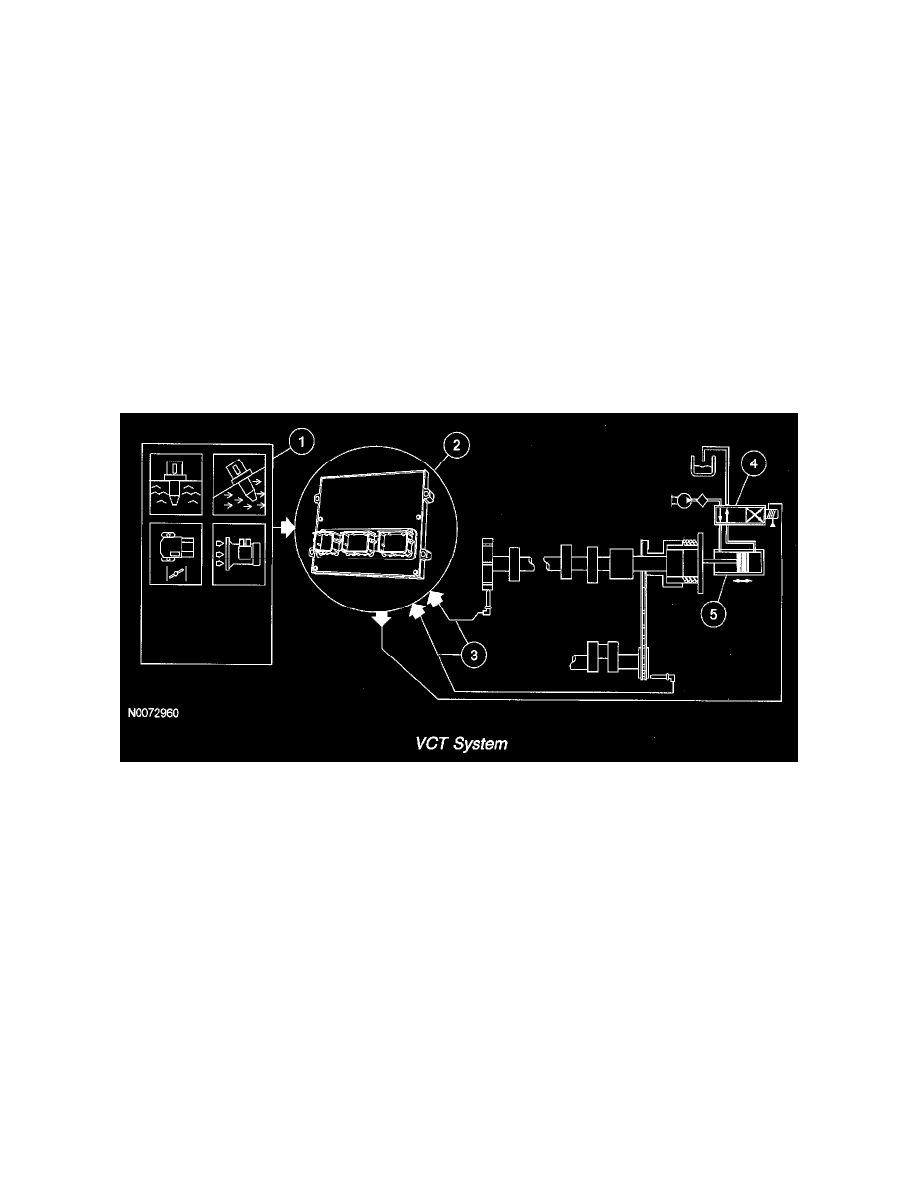

Variable Camshaft Timing (VCT) System

VCT System

The VCT system consists of an electric hydraulic positioning control solenoid, a camshaft position (CMP) sensor, and a trigger wheel. The CMP

trigger wheel has a number of equally spaced teeth equal to the number (n) of cylinders on a bank plus one extra tooth (n+1). Four cylinder and V8

engines use a CMP 4+1 tooth trigger wheel. V6 engines use a CMP 3+1 tooth trigger wheel. The extra tooth placed between the equally spaced teeth

represents the CMP signal for that bank. A crankshaft position (CKP) sensor provides the PCM with crankshaft positioning information in 10 degree

increments.

1. The PCM receives input signals from the intake air temperature (IAT) sensor, engine coolant temperature (ECT) sensor, engine oil temperature

(EOT) sensor, CMP, throttle position (TP) sensor, mass air flow (MAF) sensor, and CKP to determine the operating conditions of the engine. At

idle and low engine speeds with closed throttle, the PCM controls the camshaft position based on ECT, EOT, IAT, and MAF. During part and

wide open throttle, the camshaft position is determined by engine RPM, load and throttle position. The VCT system does not operate until the

engine is at normal operating temperature.

2. The VCT system is enabled by the PCM when the correct conditions are met.

3. The CKP signal is used as a reference for CMP positioning.

4. The VCT solenoid valve is an integral part of the VCT system. The solenoid valve controls the flow of engine oil in the VCT actuator assembly.

As the PCM controls the duty cycle of the solenoid valve, oil pressure/flow advances or retards the cam timing. Duty cycles near 0% or 100%

represent rapid movement of the camshaft. Retaining a fixed camshaft position is accomplished by dithering (oscillating) the solenoid valve duty

cycle.

The PCM calculates and determines the desired camshaft position. It continually updates the VCT solenoid duty cycle until the desired position is

achieved. A difference between the desired and actual camshaft position represents a position error in the PCM VCT control loop. The PCM