Windstar V6-232 3.8L (1995)

Alignment: Service and Repair

Front

1. Prior to aligning the front end, the subframe alignment must be checked using the following procedure.

a. Loosen subframe to body attaching bolts.

b. Shift subframe if possible in the direction necessary to bring vehicle into alignment.

c. Tighten subframe attaching bolts.

d. Recheck front alignment, if further adjustment is necessary use the following procedures.

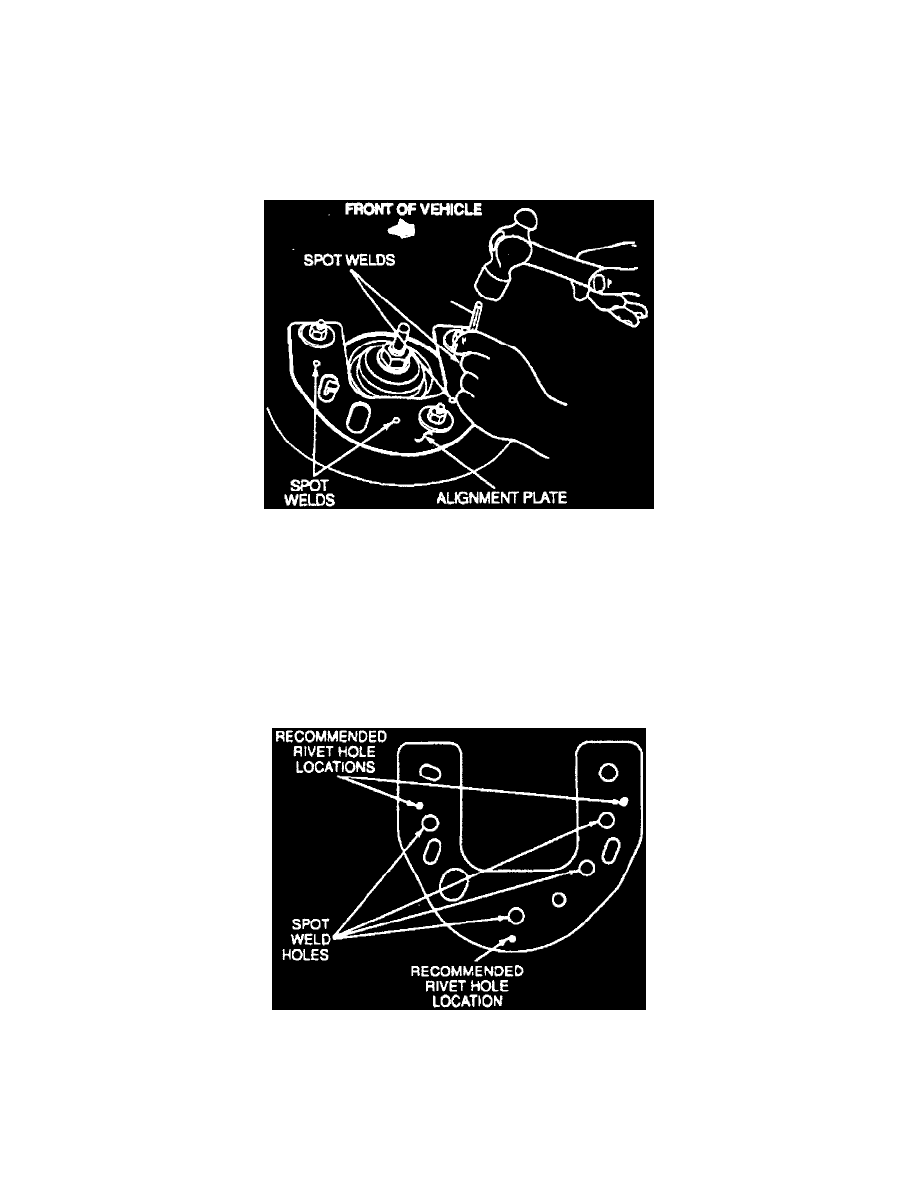

Fig. 1 Alignment Plate Loosening

2. Center punch spot welds on both strut alignment plates, then loosen strut attaching nuts, Fig. 1.

3. Using Rotunda Spot-Eze or equivalent, remove spot welds.

NOTE: Do not drill deeper than thickness of alignment plates.

4. Remove strut attaching nuts, then the alignment plates.

5. Remove burrs from strut towers and alignment plates, then paint all exposed metal on strut towers and alignment plates.

6. Install alignment plates, then loosely install strut attaching nuts.

7. Align front end, then torque strut attaching nuts to 26-30 ft. lbs.

Fig. 2 Rivet Hole Location

8. Drill three 1/8 inch holes as indicated in Fig. 2, through alignment plates and strut towers, then paint exposed metal.

CAUTION: Do not drill deeper than 3/8 inch into strut tower.

9. Install three 1/8 inch diameter pop rivets with a grip range of 1/4 inch into alignment plate/strut tower.