Suburban 1/2 Ton 4WD V8-350 5.7L (1986)

Ammeter Gauge: Testing and Inspection

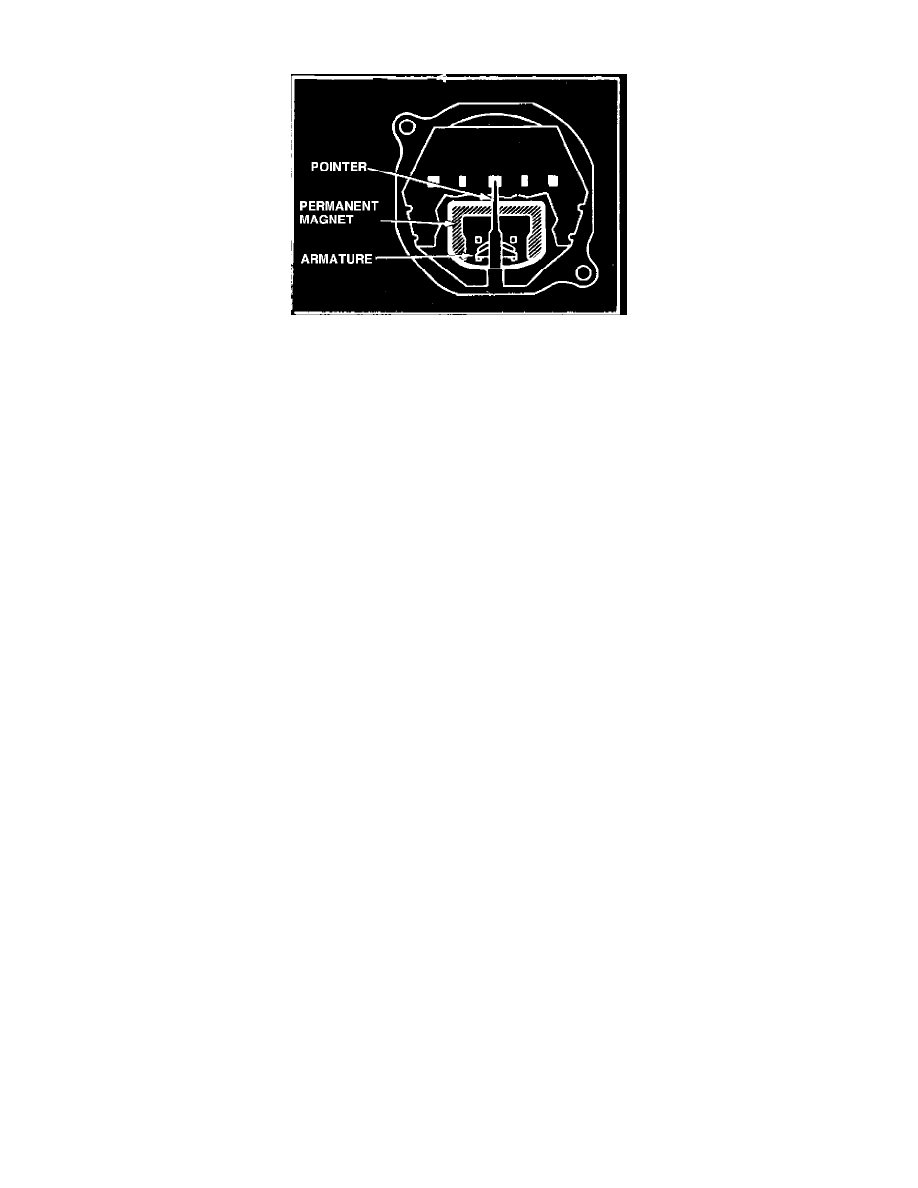

Fig. 1 Conventional type ammeter

The ammeter is an instrument used to indicate current flow into and out of the battery. When electrical accessories in the vehicle draw more current

than the alternator can supply, current flows from the battery and the ammeter indicates a discharge ( - ) condition. When electrical loads of the vehicle

are less than alternator output, current is available to charge the battery, and the ammeter indicates a charge (+) condition. If battery is fully charged, the

voltage regulator reduces alternator output to meet only immediate vehicle electrical loads. When this happens, the ammeter reads zero.

A conventional ammeter must be connected between the battery and alternator in order to indicate current flow. This type ammeter, Fig. 1, consists of

a frame to which a permanent magnet is attached. The frame also supports an armature and pointer assembly. Current in this system flows from the

alternator through the ammeter, then to the battery or from the battery through the ammeter into the vehicle electrical system, depending on vehicle

operating conditions.

When no current flows through the ammeter, the magnet holds the pointer armature so that the pointer stands at the center of the dial. When current

passes in either direction through the ammeter, the resulting magnetic field attracts the armature away from the effect of the permanent magnet, thus

giving a reading proportional to the strength of the current flowing.

TROUBLESHOOTING

When the ammeter apparently fails to register correctly, there may be trouble in the wiring which connects the ammeter to the alternator and battery or

in the alternator or battery itself.

To check the connections, first tighten the two terminal posts on the back of the ammeter. Then, following each wire from the ammeter, tighten all

connections on the ignition switch, battery and alternator. Chafed, burned or broken insulation can be found by following each ammeter wire from end to

end.

All wires with chafed, burned or broken insulation should be repaired or replaced. After this is done, and all connections are tightened, connect the

battery cable and turn on the ignition switch. The needle should point slightly to the discharge ( - ) side.

Start the engine and run slightly above idling speed. The needle should move slowly to the charge side (+).

If the pointer does not move as indicated, the ammeter is out of order and should be replaced.