Liberty 2WD L4-2.4L VIN 1 (2005)

Windshield Washer Motor: Description and Operation

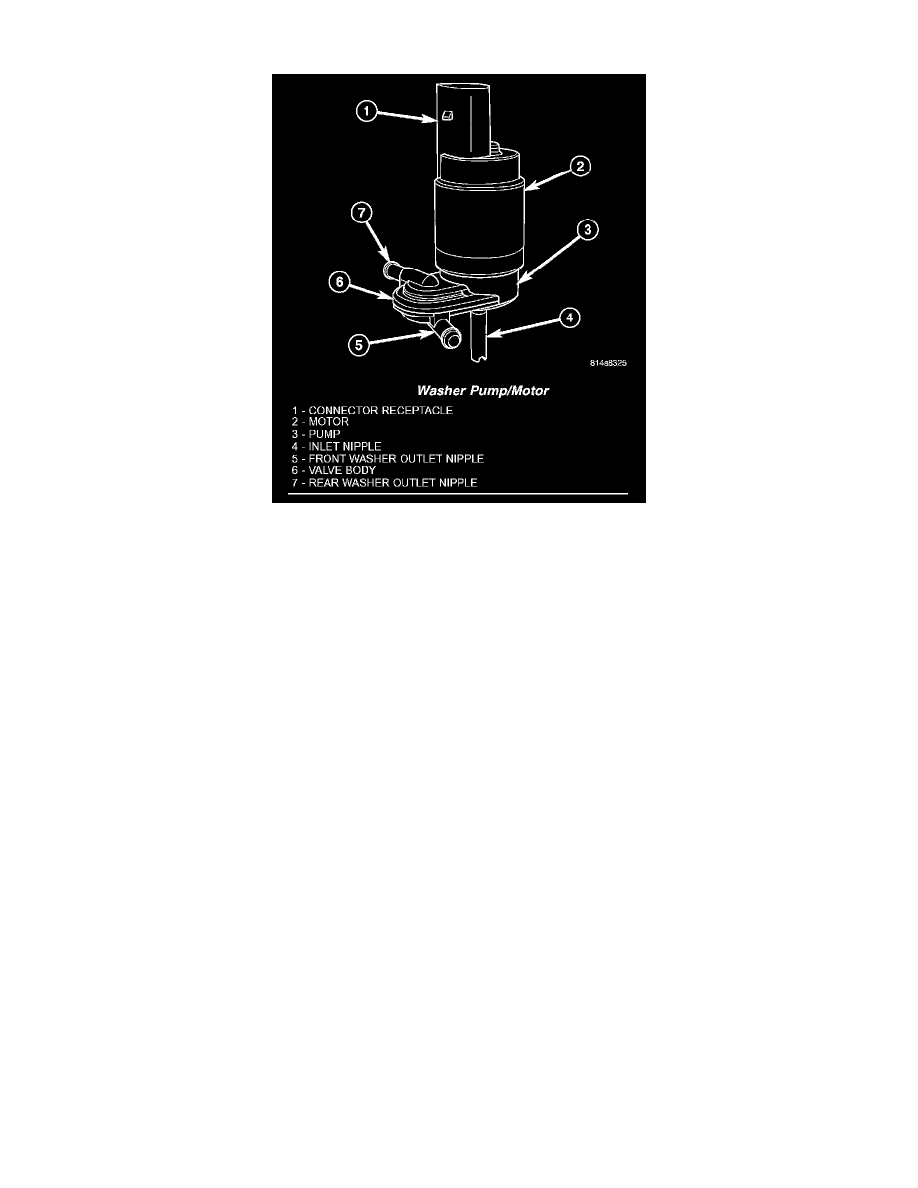

Washer Pump/Motor

The washer pump/motor unit is located on the top of a sump area of the washer reservoir, on the outboard side of the right front frame rail ahead of the

right front wheel house splash shield. A small permanently lubricated and sealed reversible electric motor is coupled to the rotor-type washer pump. The

use of an integral valve body allows the washer pump/motor unit to provide washer fluid to either the front or the rear washer systems, depending upon

the direction of the motor/pump impeller rotation.

An inlet nipple on the bottom of the pump housing passes through a rubber grommet seal/filter screen unit installed in a dedicated mounting hole of the

washer reservoir. When the pump is installed in the reservoir the blue barbed outlet nipple on the pump valve body housing connects the unit to the front

washer hose and the black barbed outlet nipple connects the unit to the rear washer hose. The number "2" molded into the front pump outlet nipple and

the number "1" molded into the rear pump outlet nipple provide further clarification of the nipple assignments.

The washer pump/motor unit is retained on the reservoir by the interference fit between the barbed pump inlet nipple and the grommet seal/filter screen,

which is a light press fit. The top of the washer pump is also secured to the washer reservoir by the use of a snap fit into a receptacle molded into the

reservoir that allows for mounting of the washer pump without the use of fasteners. An integral connector receptacle on the top of the motor housing

connects the unit to the vehicle electrical system through a dedicated take out and connector of the headlamp and dash wire harness. The washer pump/

motor unit cannot be repaired. If faulty or damaged, the entire washer pump/motor unit must be replaced.

The washer pump/motor unit features a reversible electric motor. The direction of the motor is controlled by hard wired outputs from the momentary

front and rear washer switch circuitry contained within the right (wiper) control stalk of the multifunction switch. When battery current and ground are

applied to the two pump motor terminals, the motor rotates in one direction. When the polarity of these connections is reversed, the motor rotates in the

opposite direction.

When the pump motor is energized, the rotor-type pump pressurizes the washer fluid and forces it through one of the two pump outlet nipples, and into

the front or rear washer plumbing. Washer fluid is taken in from the washer reservoir through the inlet port of the washer pump housing. An integral

valve body is located in a housing on the outlet port side of the pump housing. A diaphragm in this valve body controls which washer system plumbing

receives the washer fluid being pressurized by the pump. When the pump is not operating the diaphragm is biased to close all washer fluid flow in the

rear washer system and, in this way it also performs the function of the rear washer system check valve.

When the pump impeller rotates in the counterclockwise direction (viewed from the bottom), pressurized washer fluid is pushed out through the pump

rear outlet port and moves diaphragm to seal off the front outlet nipple opening the rear washer system outlet and nipple. When the pump impeller rotates

in the clockwise direction (viewed from the bottom), the biased diaphragm seals off the rear outlet nipple and pressurized washer fluid is pushed out

through the pump front outlet port, then the pressurized washer fluid is pushed out through the front washer outlet nipple.

The washer pump/motor unit may be diagnosed using conventional diagnostic tools and methods.