Removing Big-End Bearings during 300Tdi Engine Overhaul

ENGINE

56

OVERHAUL

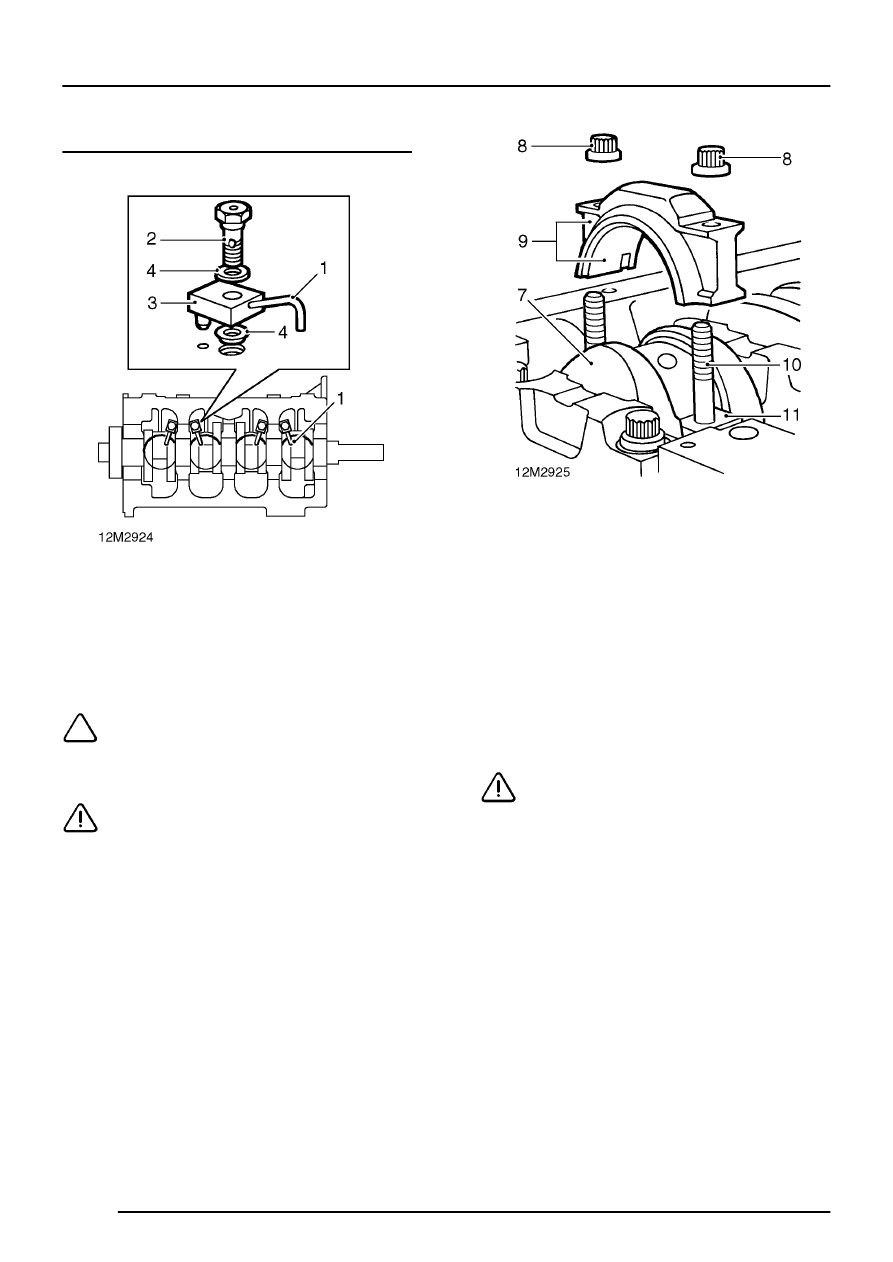

Big-end bearings - remove

1. Suitably identify each oil jet tube to its fitted

location.

2. Remove bolt securing each oil jet tube

assembly to cylinder block.

3. Remove oil jet tube assemblies.

NOTE: Dowel located.

4. Recover sealing washers.

CAUTION: Oil jet tube bolts incorporate a

non-return valve.

5. Temporarily fit crankshaft pulley bolt.

6. Suitably identify fitted position of each big-end

bearing cap to its connecting rod and each

connecting rod to its respective cylinder bore.

7. Rotate crankshaft to bring numbers 1 and 4

connecting rods to BDC.

8. Remove and discard 2 nuts securing each

big-end bearing cap.

9. Remove numbers 1 and 4 big-end bearing

caps, recover bearing shells.

10. Slide suitable pieces of plastic tubing over

each connecting rod bolt.

11. Push numbers 1 and 4 connecting rods up

cylinder bores until they are clear of crankshaft

journals.

12. Repeat above procedures to remove numbers

2 and 3 big-end bearings.

CAUTION: Big-end bearing shells must

always be replaced.