300Tdi Defender

BRAKES

11

REPAIR

REV: 09/97

Assemble outboard pistons

13. Coat new fluid seal with brake fluid. Ease seal

into groove in bore using only fingers, ensuring it

is properly seated. Fluid seal and groove are not

same in section, so when seal is seated it feels

raised to touch at edge furthest away from

mouth of bore.

14. Coat appropriate piston with brake fluid. Insert it

squarely into bore by hand only. Do not tilt piston

during insertion, leave approximately 8mm

projecting from bore.

15. Coat new wiper seal with brake fluid and fit to

new seal retainer. Slide assembly, seal first, over

protruding piston and into bore recess. Use

piston clamp to press home seal retainer and

piston.

Mounting inboard pistons

16. Clamp outboard pistons and carry out same

procedure for removing and fitting outboard

pistons and seals, instructions 8 to 15.

Fit calipers and pads

17. Fit caliper, tighten bolts evenly to

82 Nm (60

lbf/ft).

18. Connect brake flexible hoses to caliper. Tighten

to

15 Nm (11 lbf/ft).

19. Remove hose clamps.

20. Insert pads. Fit pins and springs, secure using

new split pin.

21. Bleed brake system

See Brake System Bleed

.

22. Press brake pedal firmly several times to locate

friction pads.

23. Fit road wheels, remove axle stands. Finally

tighten road wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -

100 Nm (80 lbf/ft)

Heavy duty wheels -

170 Nm (125 lbf/ft)

24. Road test vehicle. Note that new friction pads

require ’bedding-in’, this may take several

hundred miles before brakes are at maximum

efficiency.

FRONT BRAKE DISCS

Service repair no - 70.10.10.

Remove

1. Remove hub assembly

See FRONT AXLE AND

FINAL DRIVE, Repair, Front hub assembly .

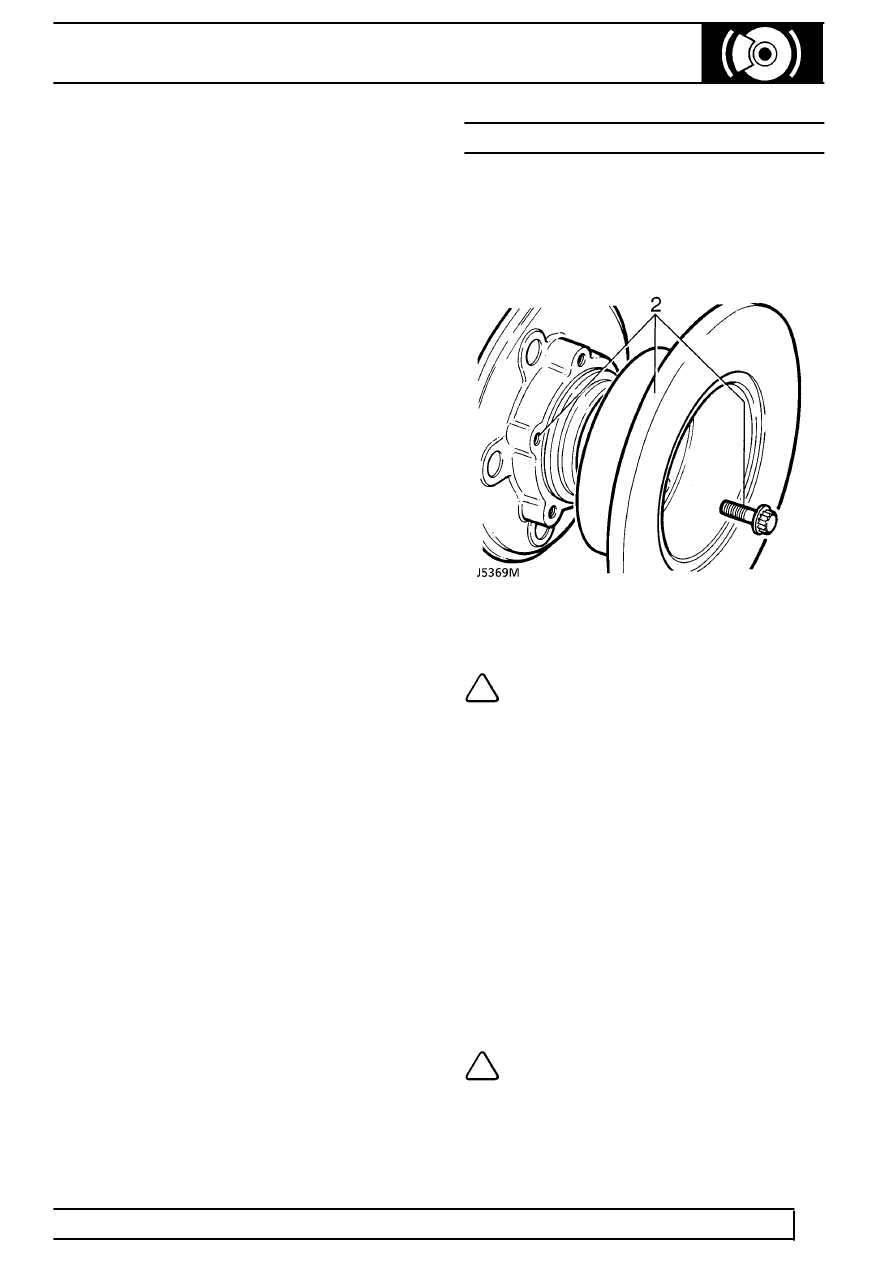

2. Remove 5 hub to disc bolts.

3. Tap disc to separate from hub.

NOTE: On 110/130 vehicles ventilated

discs are fitted as standard.

Refit

4. Locate disc to hub.

5. Apply Loctite 270 to disc bolts and tighten to

73

Nm (54 lbf/ft).

6. Check total disc runout with a dial indicator, this

must not exceed 0,15 mm, 0.006 in. If necessary

reposition disc.

7. Fit hub assembly

See FRONT AXLE AND

FINAL DRIVE, Repair, Front hub assembly .

Disc reclamation

8. Check disc thickness. This dimension may be

machined to minimum thickness of 12 mm (0.47

in.) - solid discs, 22 mm (0.90 in) - ventilated

discs. Machine equal amount off each face.

NOTE: The disc MUST BE renewed if the

minimum running thickness stamped on

the disc is recorded.