300Tdi Defender

BRAKES

17

REPAIR

HANDBRAKE CABLE

Service repair no - 70.35.25

Remove

1. Park vehicle on level ground, chock road wheels

and release handbrake. Alternatively, raise

vehicle on ramp.

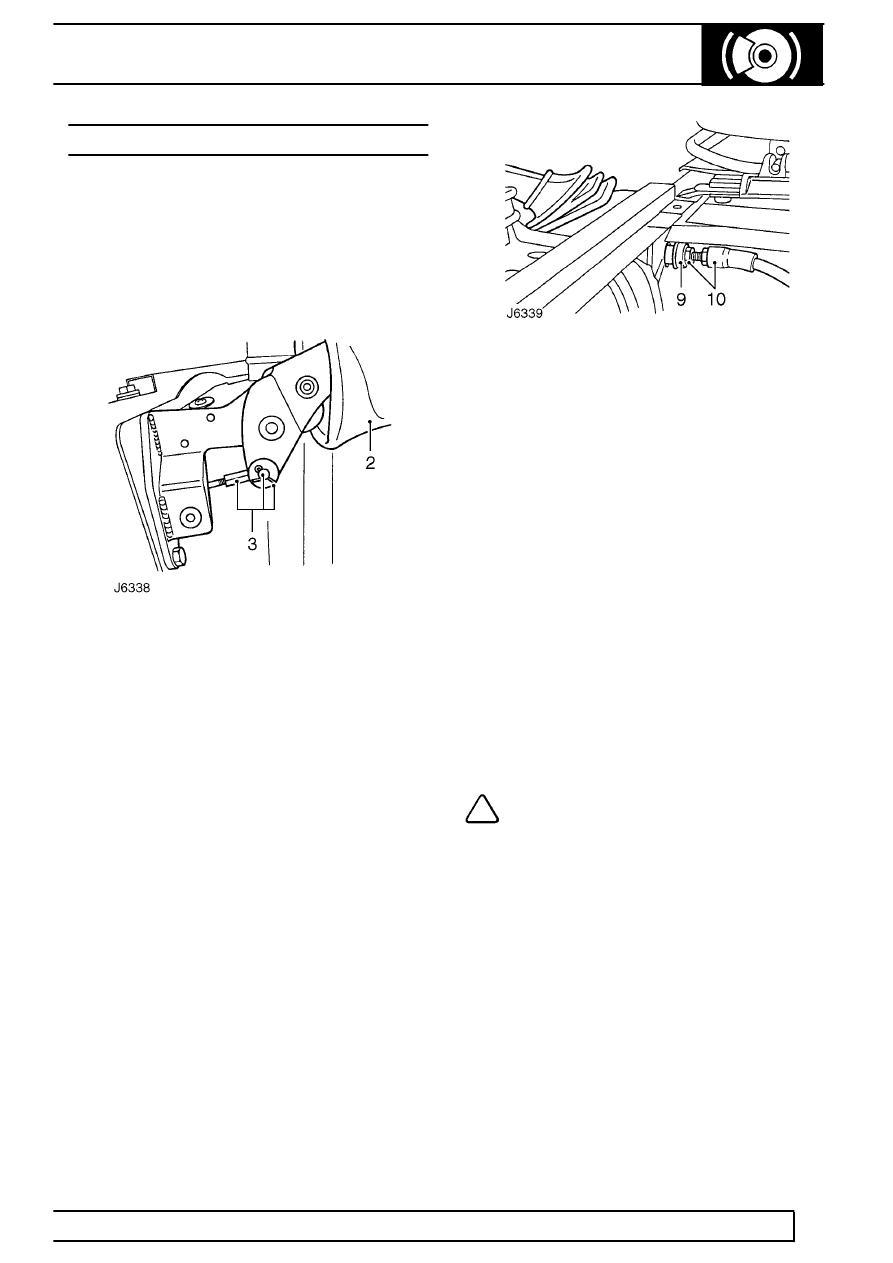

2. Remove 3 trim studs and lift up handbrake

gaiter.

3. Remove split pin, clevis pin, washer and

disconnect cable from handbrake lever.

4. Slacken off transmission brake drum adjusting

screw.

5. Disconnect propeller shaft from output flange.

6. Remove retaining screw and withdraw brake

drum.

7. Release handbrake cable clevis from abutment

on cable lever, see J6337, and pull through

aperture in back plate.

8. Pull cable from heelboard and remove from

vehicle.

Refit

9. Feed new cable through heelboard ensuring

rubber grommet is correctly located.

10. Position cable over guide plate, insert through

backplate and connect to cable lever.

11. Fit cable to handbrake lever and secure with

clevis pin and split pin.

12. Fit handbrake gaiter.

13. Fit brake drum. Tighten screw to

25 Nm (18

lbf/ft).

14. Screw in and tighten adjuster bolt until brake

drum will not rotate by hand.

15. Tighten adjuster bolt further to

25 Nm (18 lbf/ft)

to ensure brake drum is locked.

16. Slacken off adjuster bolt by 1.5 turns to give

brake shoes running clearance. Check that the

drum is free to rotate.

17. Slacken locknut and adjust cable to give the

handbrake pawl two notches free movement on

the rachet before being fully operational on third

notch (brake shoes are fully expanded against

drum).

NOTE: Cable adjustment is for a new cable

or to compensate for cable stretch. Cable

adjustment must not be used to take up

brake shoe wear.

18. Fit propeller shaft to output flange. Tighten

fixings to

46 Nm (34 lbf/ft).

19. Remove wheel chocks and check operation of

handbrake.