300Tdi Defender

CLUTCH

1

REPAIR

CLUTCH ASSEMBLY

Service repair no - 33.10.01

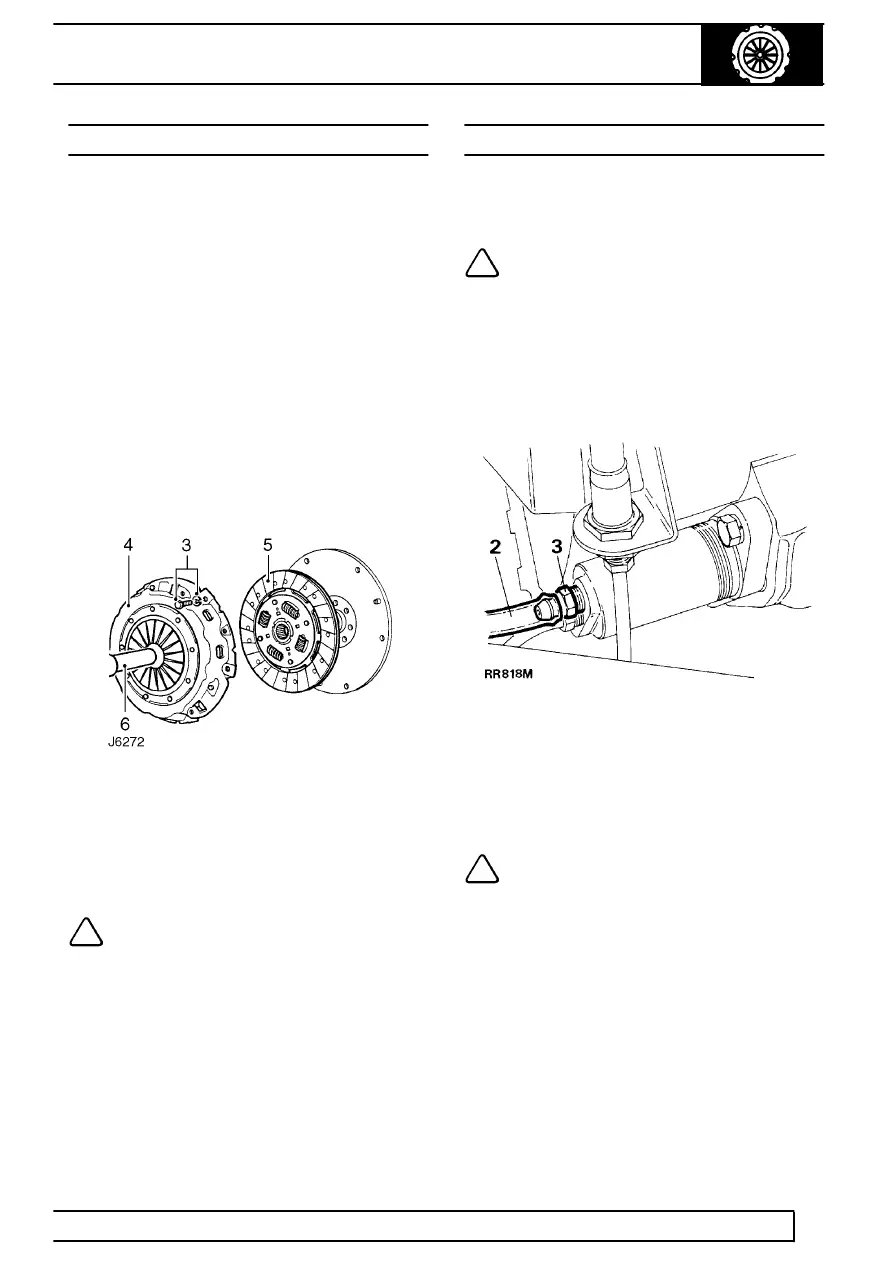

Clutch pressure plate

Renew pressure plate if diaphragm spring fingers are

worn or if pressure plate shows signs of wear, cracks

or burning.

Clutch driven plate

Renew driven plate if centre hub splines are worn or if

lining is contaminated, burned or unevenly worn.

Remove

1. Remove gearbox

See MANUAL GEARBOX,

Repair, R380 Gearbox .

2. Mark position of clutch pressure plate to flywheel

for reassembly.

3. Remove pressure plate securing bolts, working

evenly and diagonally.

4. Remove clutch assembly.

5. Withdraw clutch driven plate.

Refit

NOTE: To prevent driven plate sticking,

lubricate splines using Rocol MV 3 or

Rocol MTS 1000 grease.

6. Using centralising tool LRT-12-040 to support

clutch driven plate locate pressure plate on

flywheel dowels. If fitting original pressure plate,

align assembly marks.

7. Secure pressure plate cover fixings evenly,

working in a diagonal sequence. Tighten to

34Nm (25 lbf/ft).

8. Fit gearbox to engine

See MANUAL

GEARBOX, Repair, R380 Gearbox .

BLEED HYDRAULIC SYSTEM

Service repair no - 33.15.01

Procedure

NOTE: During bleed procedure, keep fluid

reservoir topped up to avoid introducing

air to system. For hydraulic fluid

recommendations

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information, Recommended

lubricants and fluids .

1. Attach suitable tubing to slave cylinder bleed

screw.

2. Place free end of tube in a glass jar containing

clutch fluid.

3. Loosen bleed screw.

4. Pump clutch pedal, pausing at end of each

stroke, until fluid from tubing is free of air.

NOTE: Keep free end of tube below

surface of fluid.

5. Hold clutch pedal down, tighten bleed screw.

6. Top up fluid reservoir.