300Tdi Defender

ELECTRICAL

1

FAULT DIAGNOSIS

GENERAL INFORMATION

Detailed information of electrical systems, component

locations and circuit diagrams are covered in the

Defender Electrical Troubleshooting Manual.

This section covers checks of the charging system.

GENERATOR TESTING

Service repair no - 86.10.01

Charging system check

1. Check battery is in good condition, with an open

circuit voltage of at least 12.6 V. Recharge or

substitute battery to carry out test.

2. Check drive belt condition

See SECTION 10,

Maintenance, Under bonnet maintenance.

3. Check battery connections are clean and tight.

4. Check generator connections are clean and

tight.

5. Ensure there is no drain on battery from, for

example, interior or exteriorlamps.

Generator test

Following instructions refer to use of suitable test

equipment using a carbon pile rheostat.

6. Connect test equipment referring to

manufacturer’s instructions.

7. Start engine and run at 3000 rev/min without

accessory load.

8. Rotate carbon pile load control to achieve

greatest output (amps) without allowing voltage

to fall below 12.0 V. A reading in amps, of

generator output should be obtained.

9. Run engine at 3000 rev/min, switch selector to

regulator test, read voltmeter. A reading of 13.6

to 14.4 V should be obtained.

10. Switch selector to diode/stator test, switch on

headlamps to load generator. Raise engine

speed to 3000 rev/min, read voltmeter, needle

must be within ’OK’ range.

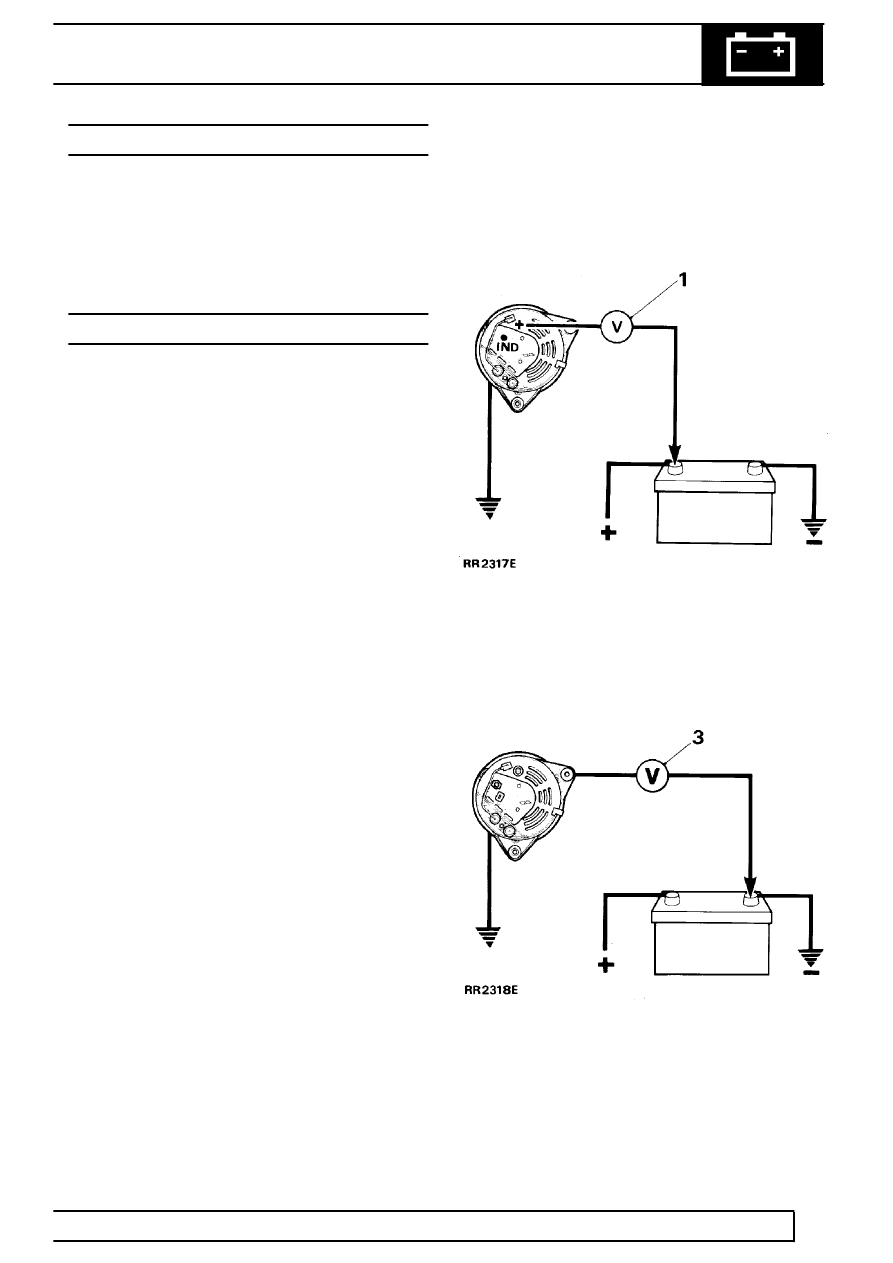

TESTING IN POSITION

Charging circuit resistance test.

1. Connect a low range voltmeter between

generator terminal marked B+ and positive

terminal of battery.

2. Switch on headlamps, start engine. Run engine

at approximately 3000 rev/min. Note voltmeter

reading.

3. Transfer voltmeter connections to frame of

generator and negative terminal of battery, and

again note voltmeter reading.

4. If reading exceeds 0.5 volt on positive side or

0.25 volt on negative side, there is a high

resistance in charging circuit which must be

traced and remedied.