300Tdi Defender Fuel System Priming Guide

19

FUEL SYSTEM

4

ADJUSTMENT

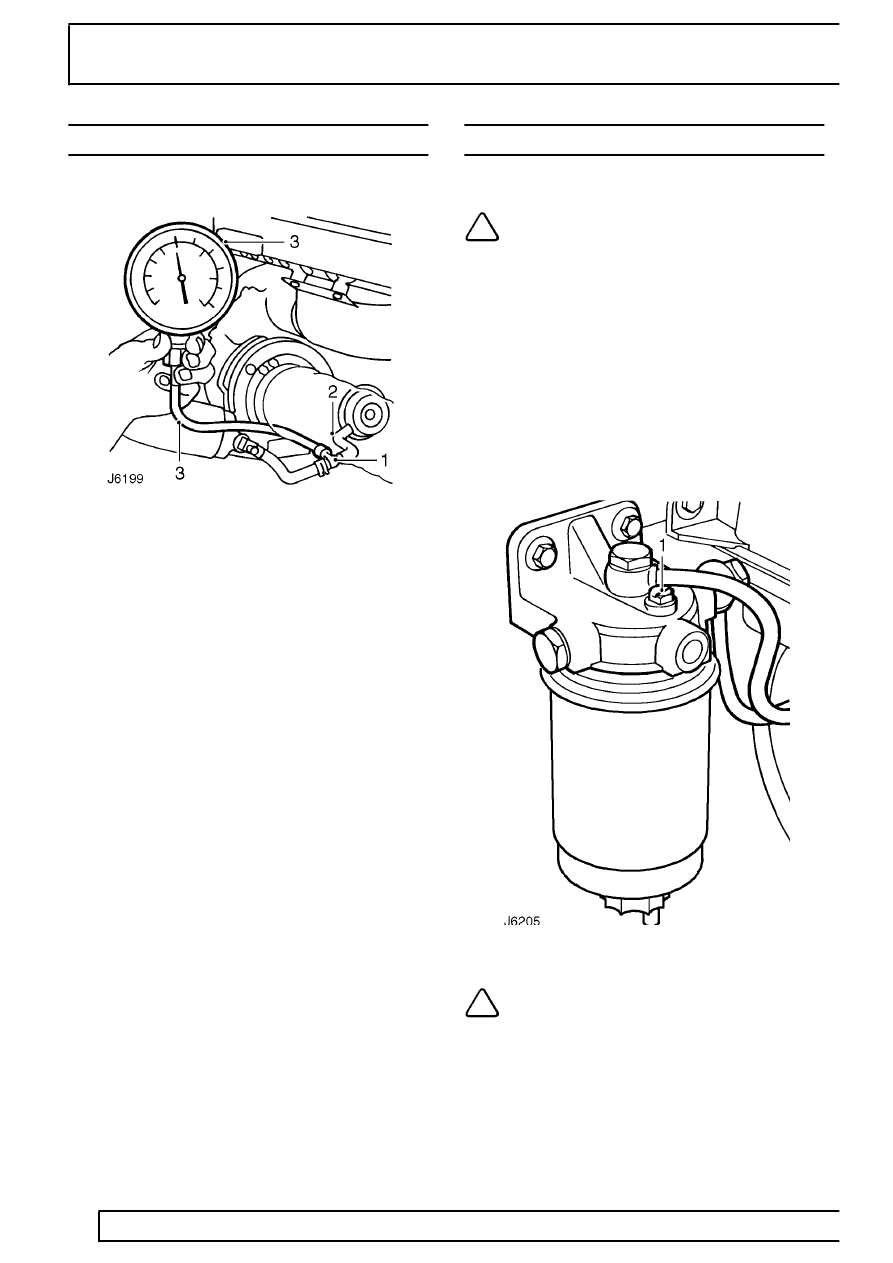

TURBOCHARGER BOOST PRESSURE - CHECK

Service repair no - 19.42.06

1. Disconnect actuator hose from turbocharger and

insert a suitable ’T’ piece connector.

2. Connect a short length of suitable hose to

turbocharger and ’T’piece.

3. Connect further hose to ’T’ piece and pressure

gauge LRT-12-011. The pressure gauge hose

must be long enough to reach into the vehicle

cab so that the gauge can be observed by driver

or passenger.

4. To check maximum boost pressure, drive

vehicle normally, but in such a manner that full

throttle can be maintained whilst climbing a hill

with engine speed held steady between 2,500

and 3,000 rev/min. Under these circumstances

boost pressure should read 0,95 - 1,09 Kgf/cm

2

(13.5 - 15.5 lb/in

2

).

PRIMING THE FUEL SYSTEM

Service repair no - 19.50.01

NOTE: If the fuel system has been

completely drained carry out the

procedures for priming both the

sedimentor, if fitted, and fuel filter and injection

pump.

Sedimentor and fuel filter

If the sedimentor or fuel filter have been dismantled

and air has entered the fuel system carry out the

following procedure:

1. Slacken fuel filter bleed screw.

2. Operate hand priming lever on fuel lift pump until

fuel, free from air, emerges from filter.

NOTE: Ensure that the fuel pump lever is

on the bottom of operating cam when

priming, otherwise maximum movement of

the lever cannot be achieved.

3. Tighten filter bleed screw whilst fuel is still

emerging.