300Tdi Defender

10

MAINTENANCE

14

MAINTENANCE

2. When pure diesel is emitted, retighten drain

plug.

3. Disconnect fuel inlet pipe at sedimenter. Raise

and support pipe above level of fuel tank to

prevent fuel draining from tank.

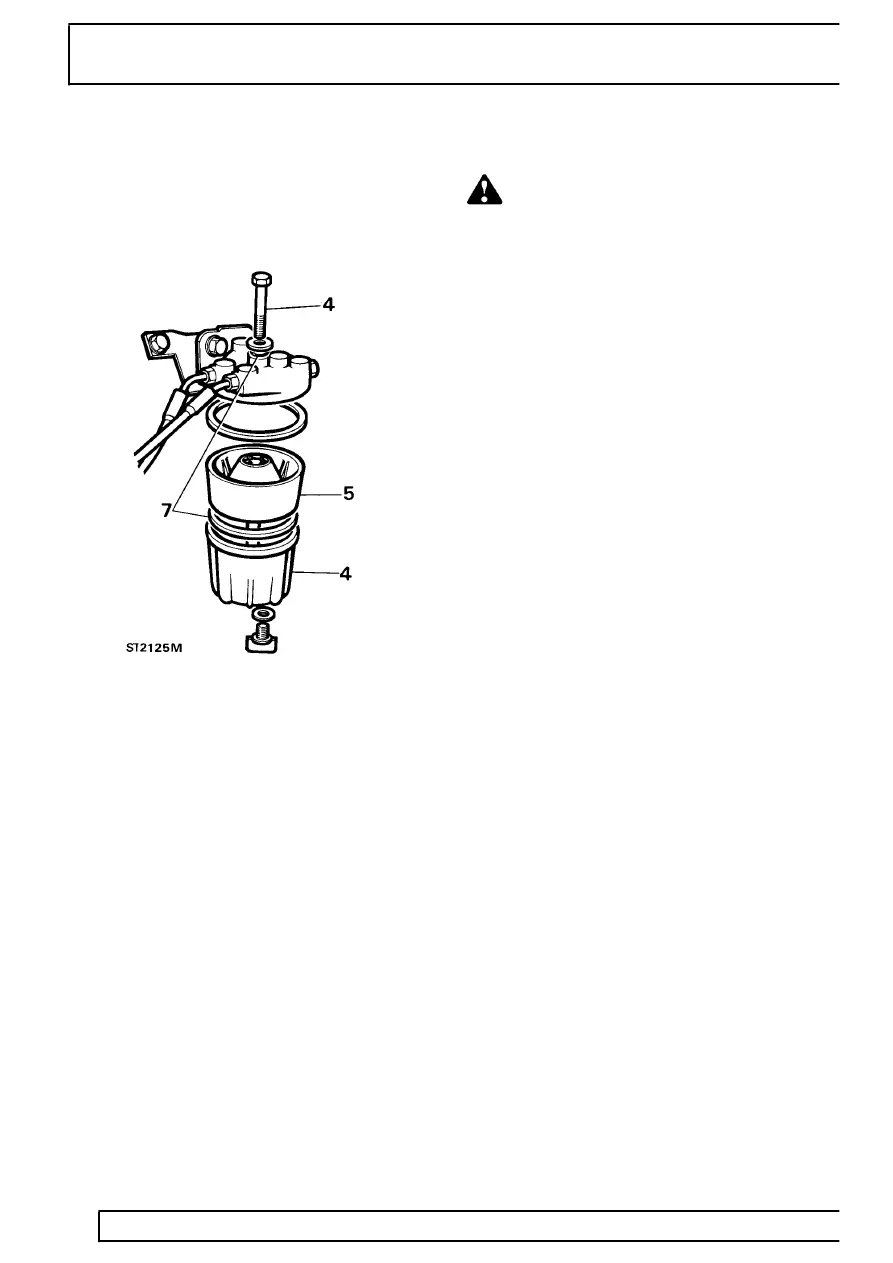

4. Support sedimenter bowl, unscrew bolt and

remove bowl.

5. Remove sedimenter element.

6. Clean all components in kerosene.

7. Fit new seals.

8. Fit element into sedimenter bowl.

9. Secure bowl to sedimenter head.

10. Fit fuel inlet pipe to sedimenter.

11. Slacken drain plug and when pure diesel is

emitted, retighten plug.

12. If necessary, prime the system.

See FUEL SYSTEM, Adjustment, Priming

the fuel system

CHECK CONDITION OF ENGINE MOUNTING

RUBBERS

CHECK SECURITY OF TOWING BRACKET

FITTINGS

CARRY OUT ROAD OR ROLLER TEST

WARNING: Two wheel roller tests MUST

NOT be carried out.

For details of dynamometer testing.

See

INTRODUCTION, Information, Dynamometer

testing

Check the following components:

1. Engine for excessive noise.

2. Clutch for slip, judder or spin/drag.

3. Gear selection/noise - high/low range.

4. Steering for abnormal noise/effort.

5. Steering for free play.

6. All instruments, gauges and warning indicators.

7. Heater and air conditioning systems.

8. Heated rear screen.

9. Shock absorbers - ride irregularities.

10. Foot brake, on emergency stop, pulling to one

side, binding and pedal effort.

11. Handbrake operation.

12. Seat reclining and latching.

13. Fully extend seat belt, check operation of

retraction and latching. Inertia belts lock when

snatched or vehicle on slope.

14. Road wheel balance.

15. Transmissions for vibrations.

16. Body noises, squeaks and rattles.

17. Excessive exhaust smoke.

18. Engine idle speed.

19. Endorse service record.

20. Report any unusual features of vehicle condition

and additional work required.

ENDORSE SERVICE RECORD