300Tdi Defender Steering Inspection for Optimal Performance

57

STEERING

6

OVERHAUL

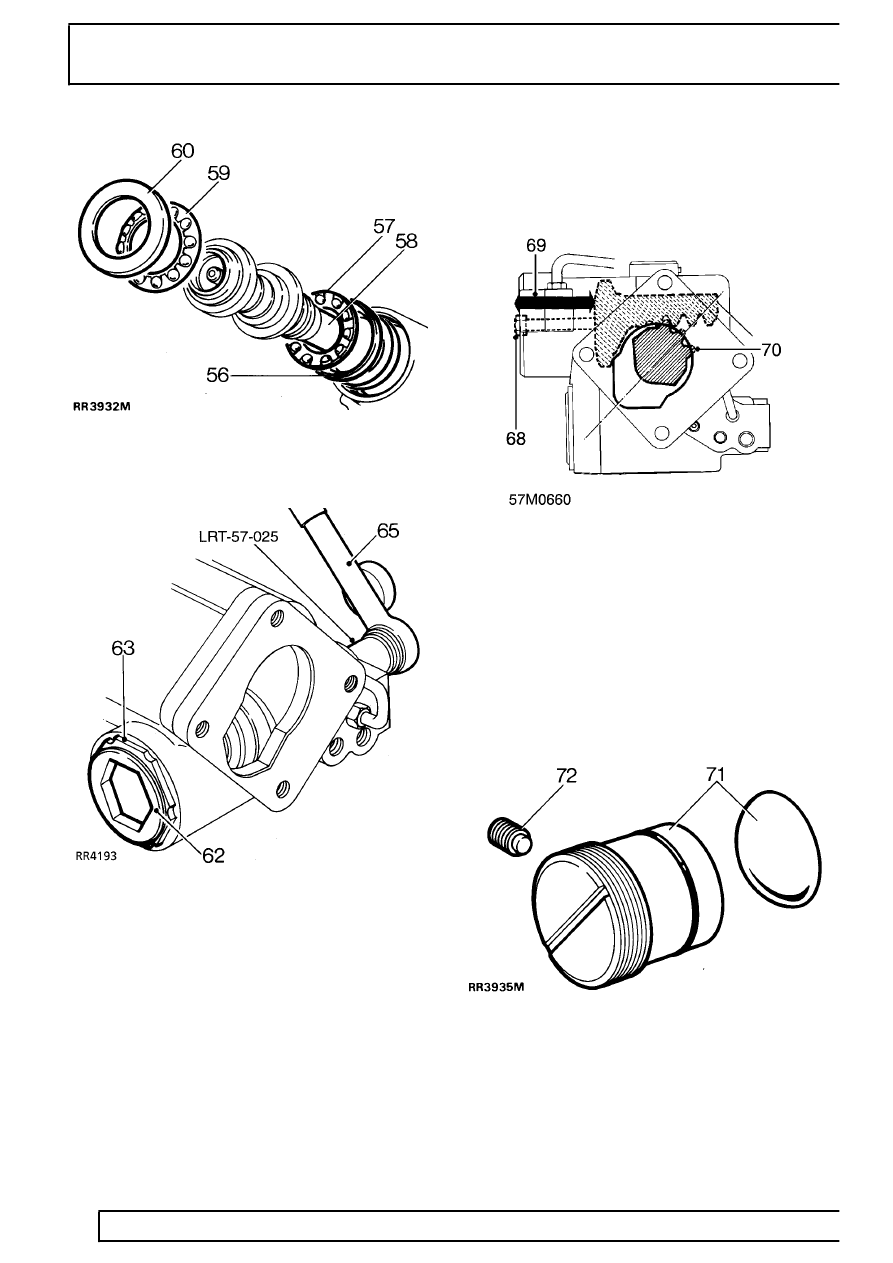

61. Fit new worm adjuster sealing ring.

62. Loosely screw adjuster into casing.

63. Fit locknut, do not tighten.

64. Turn in worm adjuster until end float is almost

eliminated. Ensure bearing cages are seated

correctly.

65. Measure maximum rolling torque of valve and

worm assembly, using a torque wrench and

spline socket LRT-57-025.

66. Turn in worm adjuster while rotating shaft to

increase figure measured to 0.56 Nm.

67. Back off worm adjuster 1/4 turn. Turn in worm

adjuster to increase reading by 0.21 - 0.34 Nm

with locknut tight,

100 Nm (74 lbf/ft). Use worm

adjusting wrench LRT-57-006and locknut

wrench LRT-57-028.

Fitting rack and piston

68. Screw slave bolt into piston to aid assembly.

69. Fit piston and rack so piston is 70 mm (2.75 in)

from outer end of bore.

Fitting sector shaft

70. Fit sector shaft using seal saver LRT-57-021.

Align roller with cut out in casing as shown. Push

in sector shaft while rotating input shaft to allow

sector roller to engage worm.

Fitting rack adjuster

71. Fit rack adjuster and thrust pad to engage rack.

Back off half turn on adjuster.

72. Loosely fit new nylon pad and adjuster set screw

assembly.