Defender Clutch Cylinder Slave Replacement Guide

33

CLUTCH

4

REPAIR

Clutch pedal setting

1. Loosen both locknuts on master cylinder push

rod.

2. Check distance from lower edge of clutch pedal

to floor. Correct measurement is 140 mm (5.50

in) without floor mat.

3. Adjust pedal stop to obtain correct setting.

4. Adjust master cylinder push rod to obtain

approximately 1.5 mm (0.06 in) free play

between push rod and master cylinder piston.

5. Tighten push rod locknuts.

6. Check operation of clutch pedal and ensure that

there is minimum of 6 mm (0.25in) of free play

before pressure is felt.

7. Fit pedal box top cover and multiplug bracket

using a new gasket and secure with screws.

8. Connect multiplug and harness clip to pedal

bracket.

9. Bleed clutch hydraulic system. See

Adjustment.

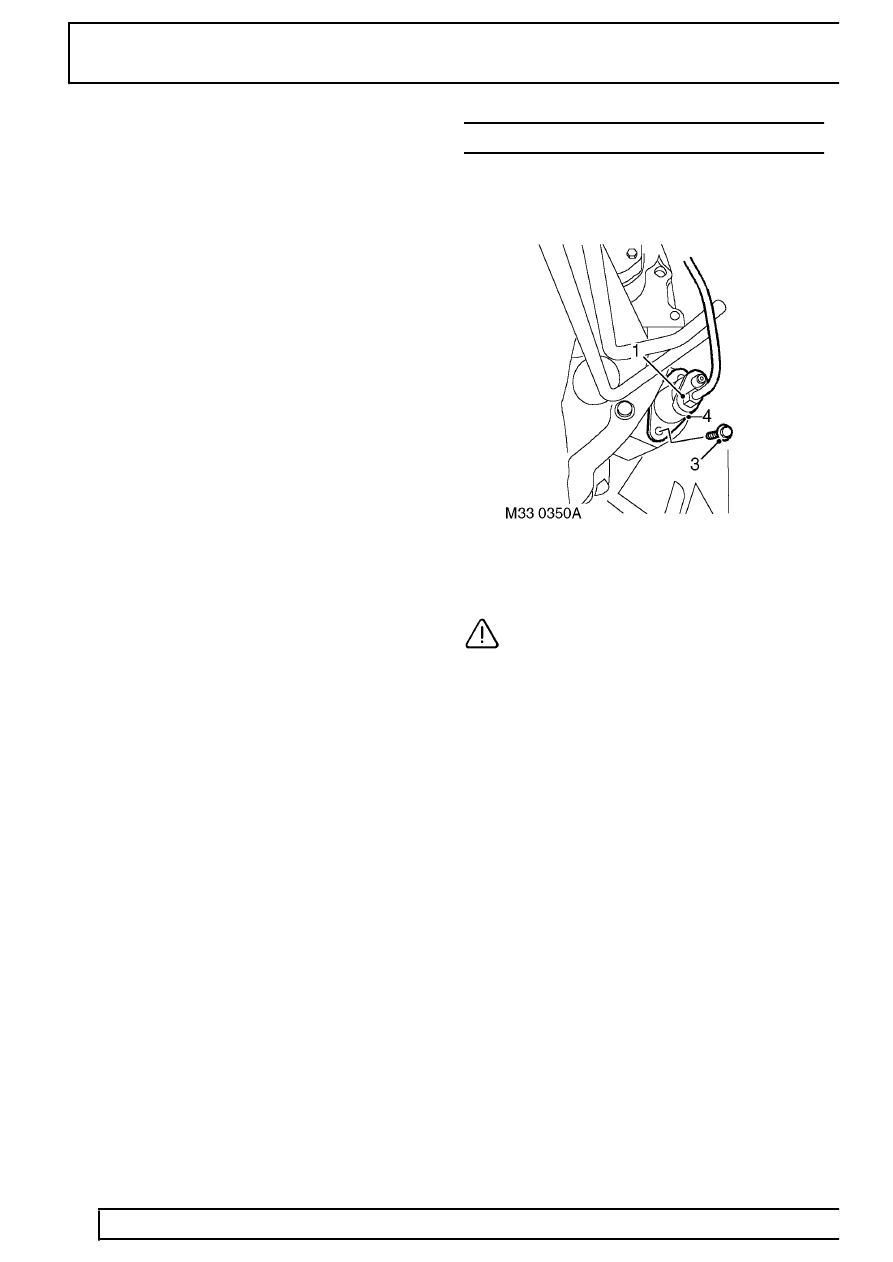

CYLINDER - CLUTCH SLAVE

Service repair no - 33.35.01

Remove

1. Disconnect pipe from slave cylinder.

CAUTION: Plug the connections.

2. Position container to catch spillage.

3. Remove 2 bolts securing slave cylinder to bell

housing.

4. Withdraw slave cylinder from bell housing and

push rod.

Refit

5. Clean ends of pipes, bell housing and slave

cylinder mating faces.

6. Lubricate end of push rod with Molybdenum

disulphide gease.

7. Locate slave cylinder to push rod and bell

housing.

8. Fit bolts and tighten to 25 Nm (18 lbf.ft).

9. Connect clutch pipe to slave clyinder.

10. Bleed clutch system. See Adjustment.