Discovery II

BODY SEALING MATERIALS

77-3-6

MATERIALS AND APPLICATIONS

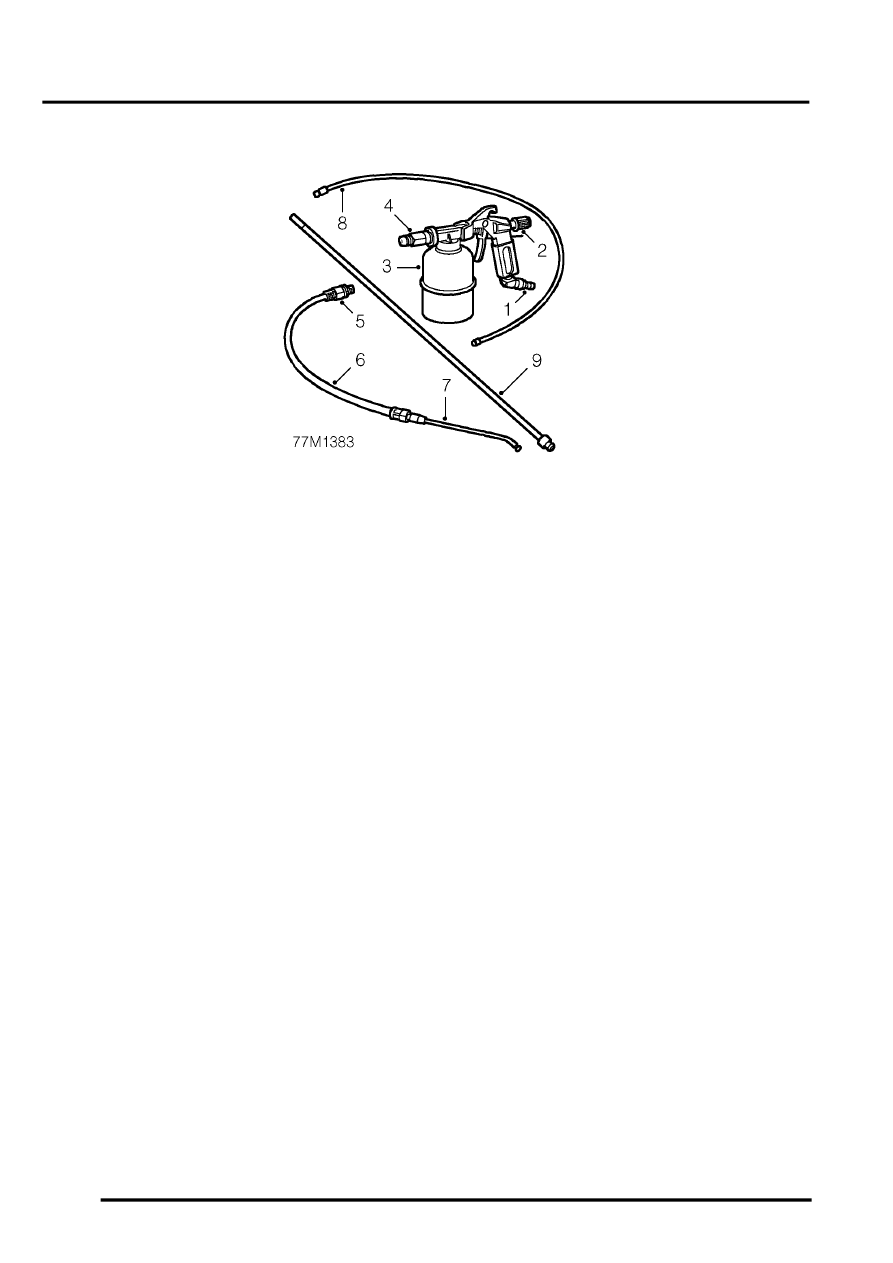

Cavity wax application equipment and techniques

1 Air inlet

2 Flow control (spray pattern adjustment)

3 Pressure cup (1 litre capacity). Maximum

pressure 140PSI (9.7 bar, 9.84 kg/cm

3

)

4 Gun connector

5 Lance nipple connection

6 Flexible lance

7 Rigid directional hook wand

(forward cone spray pattern)

8 Flexible nylon lance 1100 mm (43.307 in) with

360

°

spray pattern

9 Rigid lance 1100 mm (43.307 in) with 360

°

spray pattern

When re-treating wax-injected areas which have been disturbed during repairs, it is necessary to use a compressed

air spray gun with integral pressure cup and a selection of interchangeable lances.

The following points must be observed during use, according to the attachments fitted:

l

Use the rigid or flexible lance attachments with 360

°

spray dispersal when treating enclosed areas, to ensure

maximum coverage;

l

Where openings are restricted, use the hook nozzle to provide a more directional spray (e.g. inside narrow or

short box sections);

l

Spray exposed underbody surfaces directly from the gun less lance attachment and without disconnecting the

fluid coupling.

1100 mm (43.307 in) rigid lance

The nozzle on the rigid lance produces a 360

°

circular spray pattern combined with a forward-directed spray. Although

wax is distributed to all box section surfaces in a single stroke, effective and complete coverage is obtained in long

straight structures and box section cavities by spraying on both inward and outward strokes of the lance.

The rigid lance also provides the positional accuracy required in shaped sections, by allowing visual assessment.

CAUTION: Do not force the lance into access holes when using this attachment.

1100 mm (43.307 in) flexible nylon lance

This lance is similar in pattern to the rigid version, but provides the additional penetration required for curved sections

or in places where access is difficult. Its main limitation is a lack of positional accuracy inside box sections.

Carry out all spraying on the outward stroke of the lance. Withdraw the lance slowly to ensure sufficient coverage. Do

not withdraw the lance too quickly.

Ensure that the nylon tube of the lance is kept away from the edges of the access hole to eliminate abrasion and

extend the life of the tube. Take care to ensure that spraying ceases just before the nozzle emerges from the access

hole. To assist in this process paint the final 30 mm (1.181 in) of the nozzle with RED paint.