Discovery II

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-47

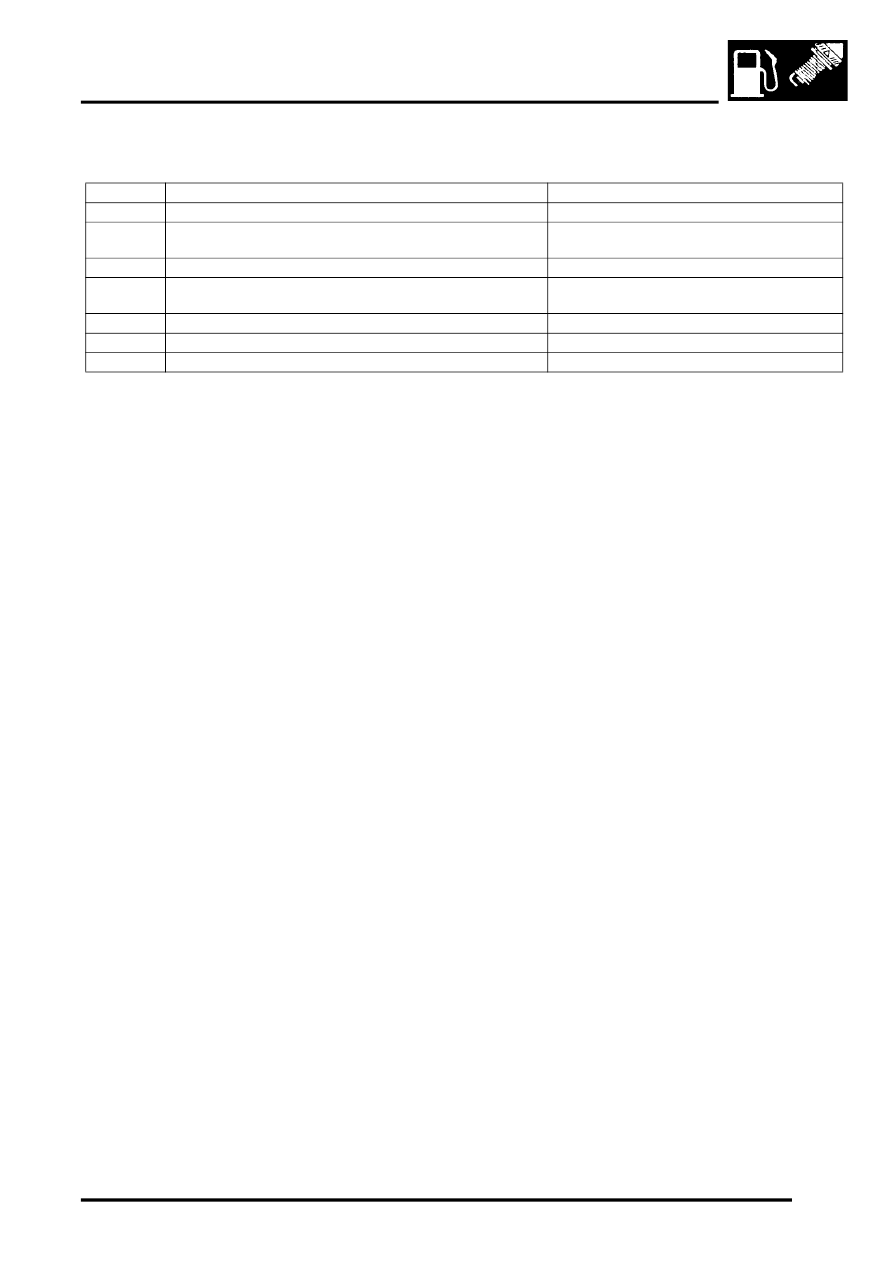

The following table shows the components itemised on the above illustration and the test applicable to each

component.

Test 1– Secondary Air Injection (SAI) Pump

Power Supply and Relay

Check all wiring and connections.

Functional Check of SAI Pump

The ECM checks the engine coolant temperature when the engine is started in addition to checking the elapsed time

since the last engine start. The engine coolant temperature must be below 55

°

C (131

°

F) and the ambient temperature

above 8

°

C (46

°

F) for the SAI pump to run. Also, depending on the long term 'modelled' ambient temperature

determined by the ECM, the minimum time elapsed required since the last engine start can be up to 8.25 hours. The

period of time that the SAI pump runs for depends on the starting temperature of the engine and varies from

approximately 95 seconds for a start at 8

°

C (46

°

F) to 30 seconds for a start at 55

°

C (131

°

F).

With a warm engine which is switched off and the SAI pump relay removed, the SAI pump can be supplied with power

by bridging terminals 87 and 30 at the relay socket.

CAUTION: Ensure that terminals 87 and 87a are not connected or bridged in any way, a short circuit will

occur.

NOTE: TestBook/T4 can also be used to force the SAI system to perform an SAI active diagnostic routine. During this

routine the SAI pump will run for approximately 10 seconds.

When the terminals are bridged or the diagnostic routine initiated, the pump must run when requested which will be

noticeable by the running noise of the pump. Only allow the SAI pump to run for a maximum of 90 seconds and allow

sufficient time for the pump to cool down before running again.

If the SAI pump does not run or makes a scraping noise, it must be replaced. In this case, all other system components

must also be checked.

Noise Complaints

If the SAI pump runs but the operating noise is excessively loud, the external components of the pump, cable, hose

line, and decoupling segments, must be checked. Check the decoupling segments and hose line for distortion and

the cable and hose line for contact with the pump body.

If excessive noise still occurs, the SAI pump must be replaced.

NOTE: Before a new SAI pump is fitted, the SAI control valves must checked for correct function and tightness – Refer

to Test 2 – Secondary Air Injection (SAI) Control Valves.

When fitting a new SAI pump, ensure that the hose lines, the cable and the decoupling segments are fitted without

tension and contact with the pump body.

Item No.

Component Description

Applicable Test

1

SAI Pump

Test 1 – Secondary Air Injection (SAI) Pump

2

SAI control valves (1 per engine bank)

Test 2 – Secondary Air Injection (SAI) Control

Valves

3

Vacuum solenoid valve

Test 3 – Vacuum Solenoid Valve

4

Delivery hoses to SAI control valves

Test 4 – Delivery Hoses to Secondary air

Injection (SAI) Control Valves

5

Connection to air manifold (SAI rail)

Test 5 – Connection to Air Manifold

6

Vacuum line (intake manifold to vacuum solenoid valve)

Test 6 – Vacuum Lines

7

Vacuum lines (vacuum solenoid valve to SAI control valves)

Test 6 – Vacuum Lines