Discovery II

HEATING AND VENTILATION

DESCRIPTION AND OPERATION

80-9

FBH fuel pump

The FBH fuel pump regulates the fuel supply to the FBH unit. The FBH fuel pump is installed in a rubber mounting on

the chassis crossmember immediately in front of the fuel tank. The pump is a self priming, solenoid operated plunger

pump, with a fixed displacement of 0.063 ml/Hz. The ECU in the FBH unit outputs a pulse width modulated signal to

control the operation of the pump. When the pump is de-energised, it provides a positive shut-off of the fuel supply to

the FBH unit.

FBH fuel pump nominal operating speeds/outputs

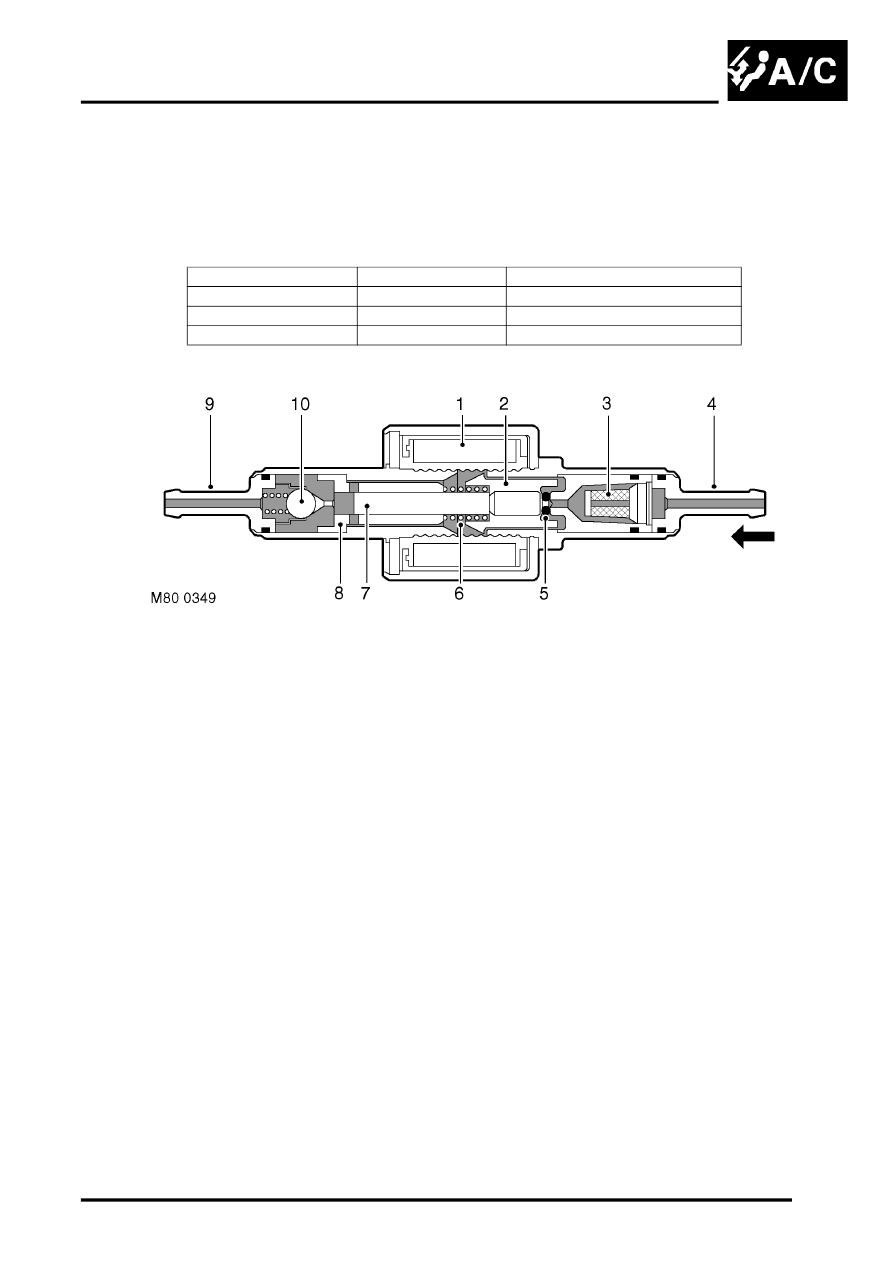

Sectioned view of FBH fuel pump

1 Solenoid coil

2 Plunger

3 Filter insert

4 Fuel line connector

5 'O' ring seal

6 Spring

7 Piston

8 Bush

9 Fuel line connector

10 Non return valve

The solenoid coil of the FBH fuel pump is installed around a housing which contains a plunger and piston. The piston

locates in a bush, and a spring is installed on the piston between the bush and the plunger. A filter insert and a fuel

line connector are installed in the inlet end of the housing. A non return valve and a fuel line connector are installed

in the fuel outlet end of the housing.

While the solenoid coil is de-energised, the spring holds the piston and plunger in the 'closed' position at the inlet end

of the housing. An 'O' ring seal on the plunger provides a fuel tight seal between the plunger and the filter insert,

preventing any flow through the pump. When the solenoid coil is energised, the piston and plunger move towards the

outlet end of the housing, until the plunger contacts the bush, and draw fuel in through the inlet connection and filter.

The initial movement of the piston also closes transverse drillings in the bush and isolates the pumping chamber at

the outlet end of the housing. Subsequent movement of the piston then forces fuel from the pumping chamber through

the non return valve and into the line to the FBH unit. When the solenoid coil de-energises, the spring moves the piston

and plunger back towards the closed position. As the piston and plunger move towards the closed position, fuel flows

passed the plunger and through the annular gaps and transverse holes in the bush to replenish the pumping chamber.

Operating phase

Speed, Hz

Output, l/h (US galls/h)

Start sequence

0.70

0.159 (0.042)

Part load

1.35

0.306 (0.081)

Full load

2.70

0.612 (0.163)