Discovery II

PAINTING

77-5-2

PROCEDURES

Paint preparation

Paint refinishing

The following process must be adhered to for paint refinishing operations.

1 Seal required exterior and interior seams with an approved seam sealer

BODY SEALING MATERIALS, MATERIALS AND APPLICATIONS, Approved materials.

2 Repair any damage to underbody sealers

CORROSION PREVENTION AND SEALING, CORROSION PREVENTION, Corrosion prevention.

3 Apply a two-pack paint refinishing system

4 Apply cavity wax to all interior surfaces which have not received refinish paint

Paint repairs

Before carrying out paintwork repairs, clean the vehicle thoroughly using either a steam cleaner or high-pressure

washer.

Wash locally repaired areas using a mild water-mixable detergent and wipe them clean with solvent, immediately

before paint application.

Ensure that damaged paintwork which has led to exposed metal is abraded until the metal is clean, extending beyond

the area of the original damage. Treat the bare metal with an etch phosphate to remove all traces of rust and to provide

a key for new paint coats. Re-treat the affected area using either a separate acid-etch primer and two-pack surfacer

or an integrated etch primer/filler, and follow with a two-pack paint system. Treat those surfaces not receiving paint

using an approved cavity wax, following paint operations.

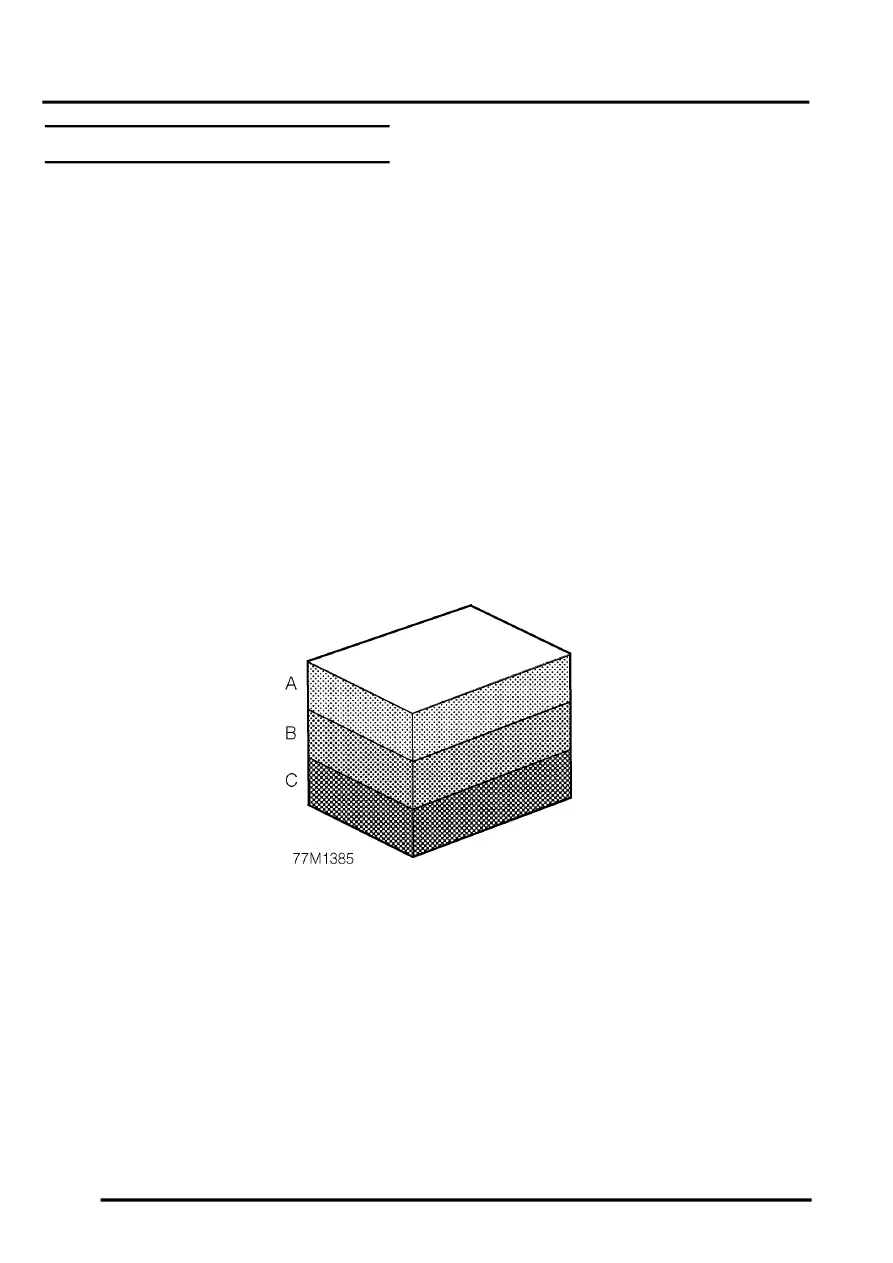

a Two-pack top coat

b Two-pack primer filler and etch primer

c Etch phosphate

When heat curing paint repairs, the temperature must not exceed 65

°

C (149

°

F). Temperatures above this

figure will cause the reflective elements within the headlamps and taillamps to distort.