Discovery II

PANEL REPAIRS

PROCEDURES 77-2-15

PROCEDURES

Panel replacement procedure

This procedure is designed to explain the basic panel

removal and replacement method. The main criterion

in removal and replacement of body panels is that

the original standard is maintained as far as possible.

While individual repairs will differ in detail, this

procedure has been devised placing emphasis on

ease of repair and the elimination of unnecessary

work.

Body panels are being increasingly manufactured in

high strength steels to meet design requirements for

safety and weight saving. As panels in high strength

steels cannot be visually identified, and as they are

more sensitive to excess heat than panels

manufactured from low carbon steel, it is advisable

that the following procedure be observed at all times.

Remove panel

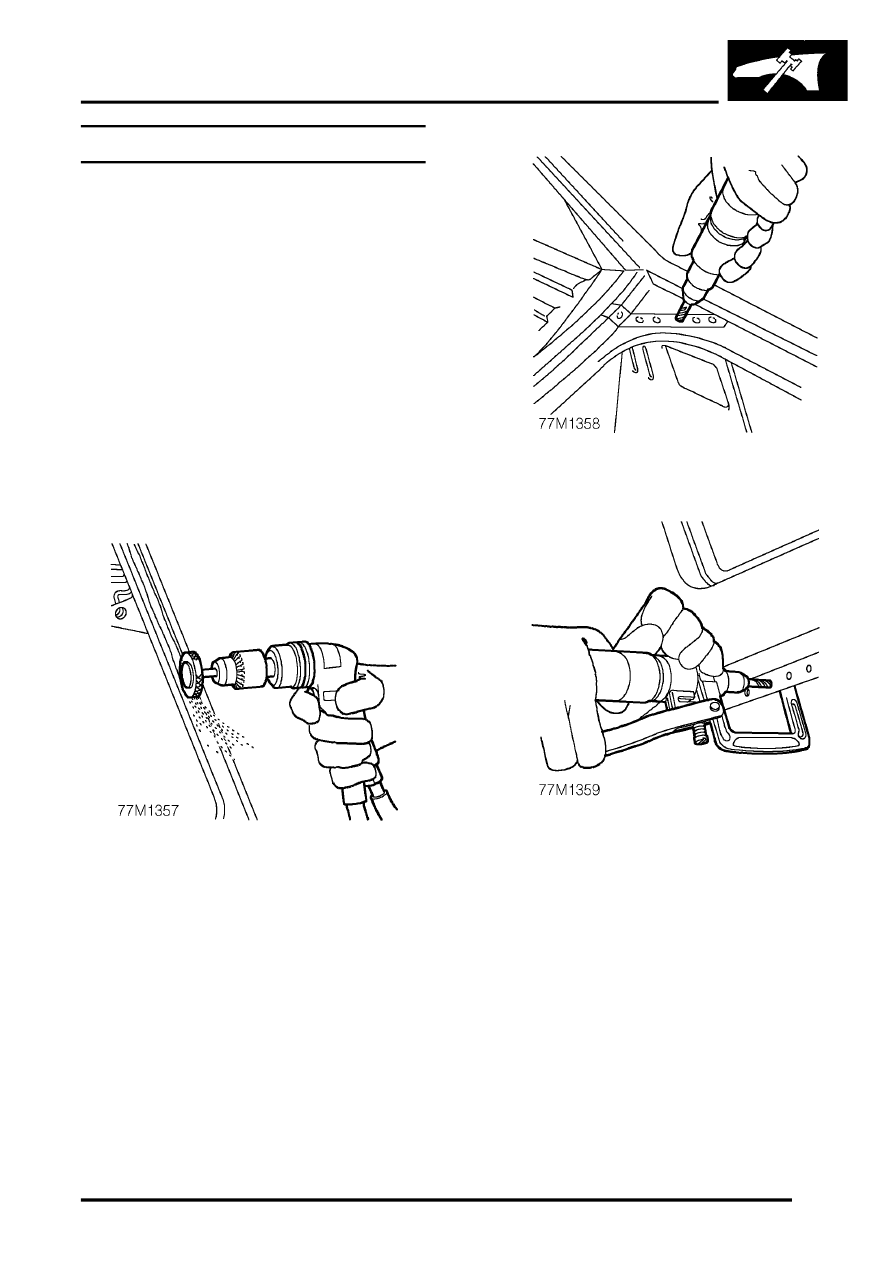

1. Expose resistance spot welds. For those spot

welds which are not obviously visible, use a

rotary impregnated wire brush fitted to an air

drill, or alternatively a hand held wire brush.

NOTE: In wheel arch areas it may be necessary

to soften underbody coating, using a hot air

gun, prior to exposing spot welds.

2. Cut out welds using a cobalt drill.

3. Alternatively, use a clamp-type spot weld

remover.