300Tdi Discovery

GENERAL FITTING REMINDERS

7

INFORMATION

COTTER PINS

1. Fit new cotter pins throughout when replacing

any unit.

2. Always fit cotter pins where cotter pins were

originally used. Do not substitute spring

washers: there is always a good reason for the

use of a cotter pin.

3. All cotter pins should be fitted as shown unless

otherwise stated.

NUTS

1. When tightening a slotted or castellated nut

never loosen it back to insert cotter pin or locking

wire except in those recommended cases where

this forms part of an adjustment. If difficulty is

experienced, alternative washers or nuts should

be selected, or washer thickness reduced.

2. Where self-locking nuts have been removed it is

advisable to replace them with new ones of the

same type.

NOTE: Where bearing pre-load is involved

nuts should be tightened in accordance

with special instructions.

LOCKING WIRE

1. Fit new locking wire of the correct type for all

assemblies incorporating it.

2. Arrange wire so that its tension tends to tighten

the bolt heads, or nuts, to which it is fitted.

SCREW THREADS

1. Both UNF and Metric threads to ISO standards

are used. See below for thread identification.

2. Damaged threads must always be discarded.

Cleaning up threads with a die or tap impairs the

strength and closeness of fit of the threads and

is not recommended.

3. Always ensure that replacement bolts are at

least equal in strength to those replaced.

4. Do not allow oil, grease or jointing compound to

enter blind threaded holes. The hydraulic action

on screwing in the bolt or stud could split the

housing.

5. Always tighten a nut or bolt to the recommended

torque value. Damaged or corroded threads can

affect the torque reading.

6. To check or re-tighten a bolt or screw to a

specified torque value first loosen a quarter of a

turn, then re-tighten to the correct value.

7. Oil thread lightly before tightening to ensure a

free running thread, except in the case of

threads treated with sealant/lubricant, and

self-locking nuts.

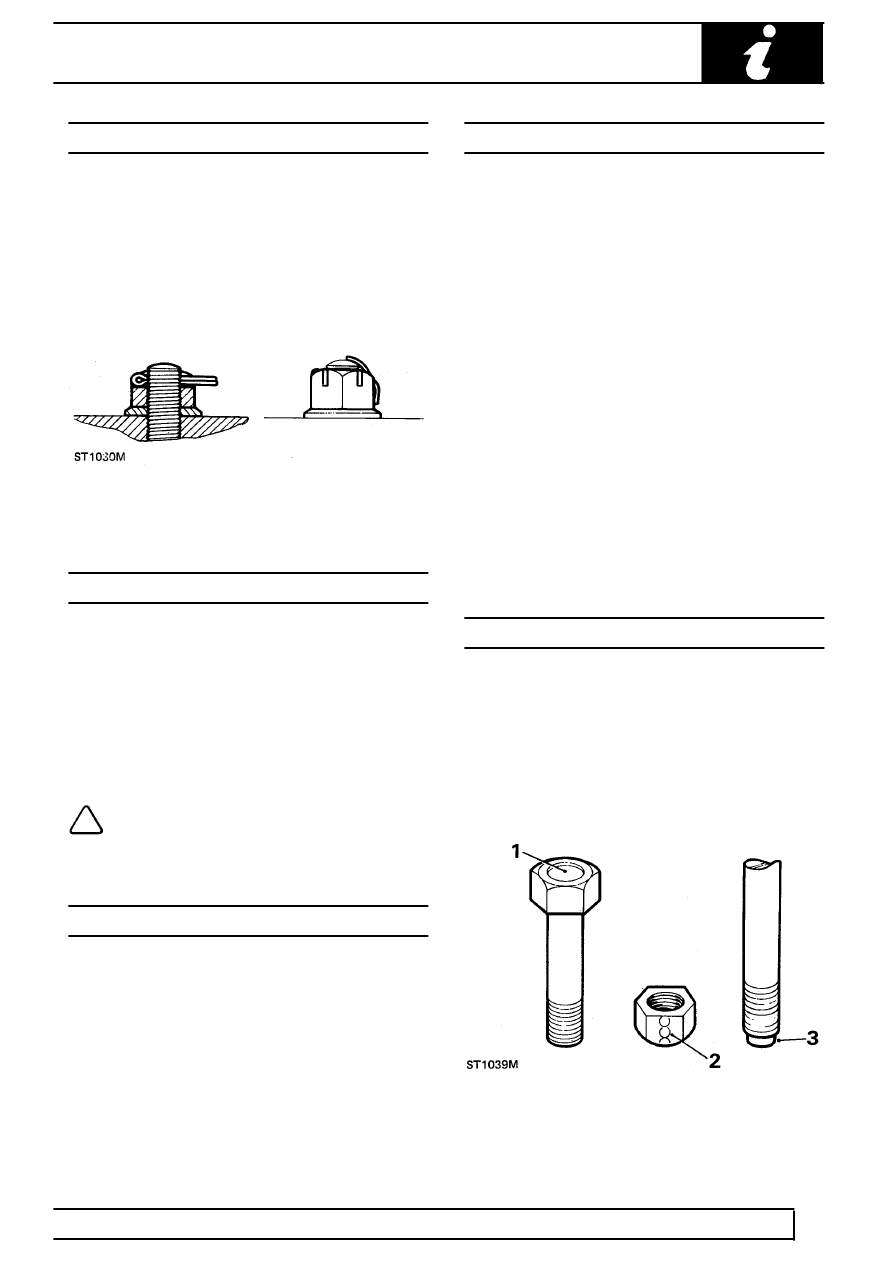

UNIFIED THREAD IDENTIFICATION

1. Bolts

A circular recess is stamped in the upper surface

of the bolt head.

2. Nuts

A continuous line of circles is indented on one of

the flats of the hexagon, parallel to the axis of

the nut.

3. Studs, Brake Rods, etc.

The component is reduced to the core diameter

for a short length at its extremity.