300Tdi Discovery: Repairing Cylinder Head Gasket - Page 165

12

ENGINE

22

REPAIR

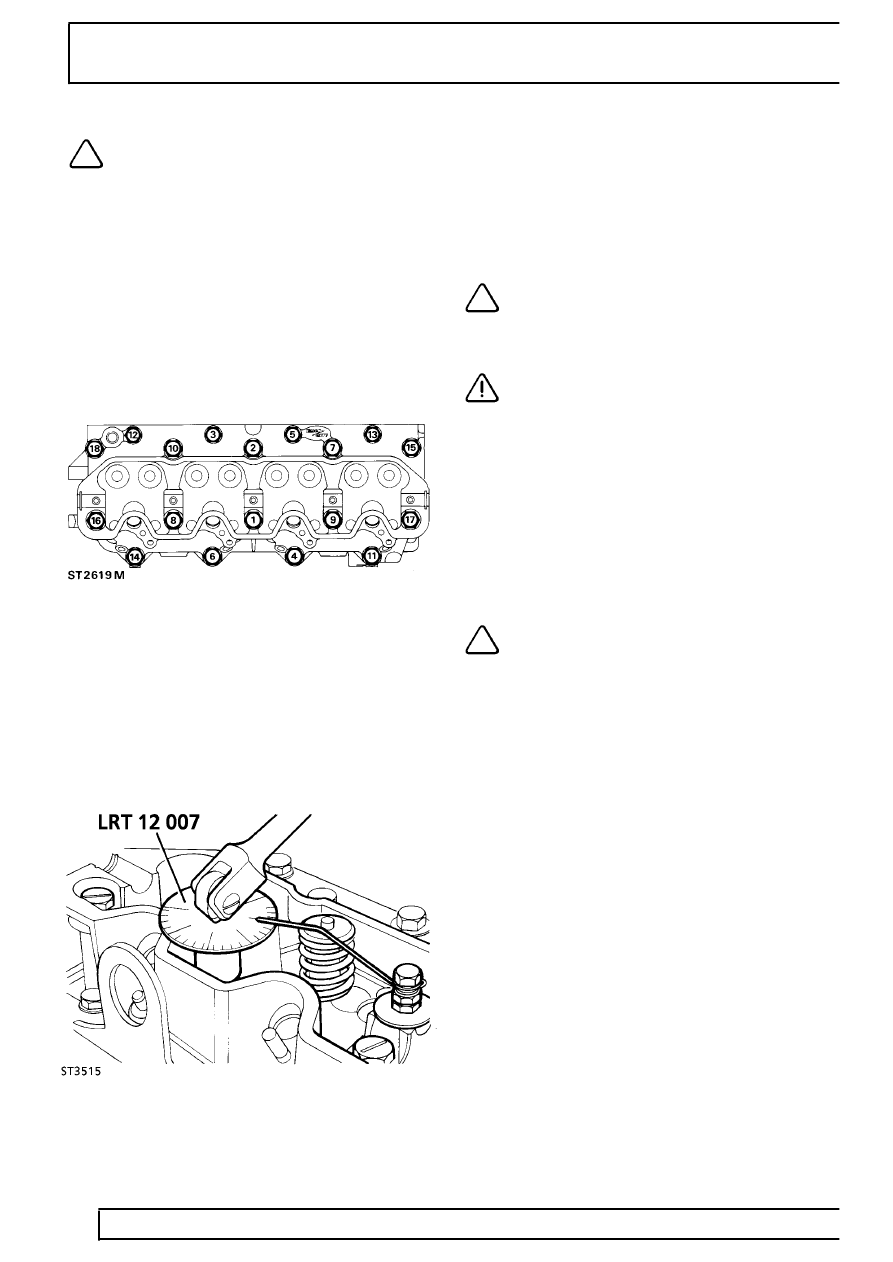

NOTE: Cylinder head retaining bolts can

be used up to a maximum of five times.

34. Lubricate threads of bolts with light oil and fit to

positions illustrated.

Bolt sizes:

M10 x 117mm locations 3, 5, 12, and 13.

M12 x 140mm locations 1, 2, 7, 8, 9, 10, 15, 16, 17,

and 18.

M12 x 100mm locations 4, 6, 11, 14.

35. Tighten bolts so that underside of heads just

make contact with cylinder head.

36. Following the sequence illustrated tighten all

bolts to

40 Nm.

37. Attach degree disc special tool LRT-12-007 to a

power bar.

38. Make a suitable pointer from welding rod and

attach to a bolt screwed into a rocker shaft

securing bolt hole.

39. Tighten all bolts through 60

°

strictly in sequence

illustrated.

40. Repeat 60

°

tightening procedure, again strictly in

sequence illustrated.

41. Tighten the ten longer bolts (M12 x 140mm) a

further 20

°

, again following the sequence

illustrated.

NOTE: Repositioning of the pointer will be

necessary to reach all bolts, the pointer

can be fitted to the rocker shaft securing

studs using two nuts.

CAUTION: The double tightening

procedure must be carried out, on no

account should tightening be performed in

one operation, otherwise damage to the cylinder

head may occur.

42. Fit valve stem caps.

43. Fit push rods to locations from which they were

removed.

44. Fit rocker shaft assembly evenly tightening

securing nuts and bolts to correct torque.

45. Fit rocker cover ensuring oil seal is satisfactory

for continued use.

NOTE: Rocker cover seals can be re-used

up to a maximum of five times.

46. Secure rocker cover with special seal washers

and nuts tightened to correct torque.

47. Refit remainder of items by reversing operations

1 to 22 tightening securing bolts to correct torque

where applicable.