300Tdi Discovery - ENGINE - V8i - Drive Belt Tension Check

12

ENGINE

2

REPAIR

Remove

1. Remove fan cowl upper.

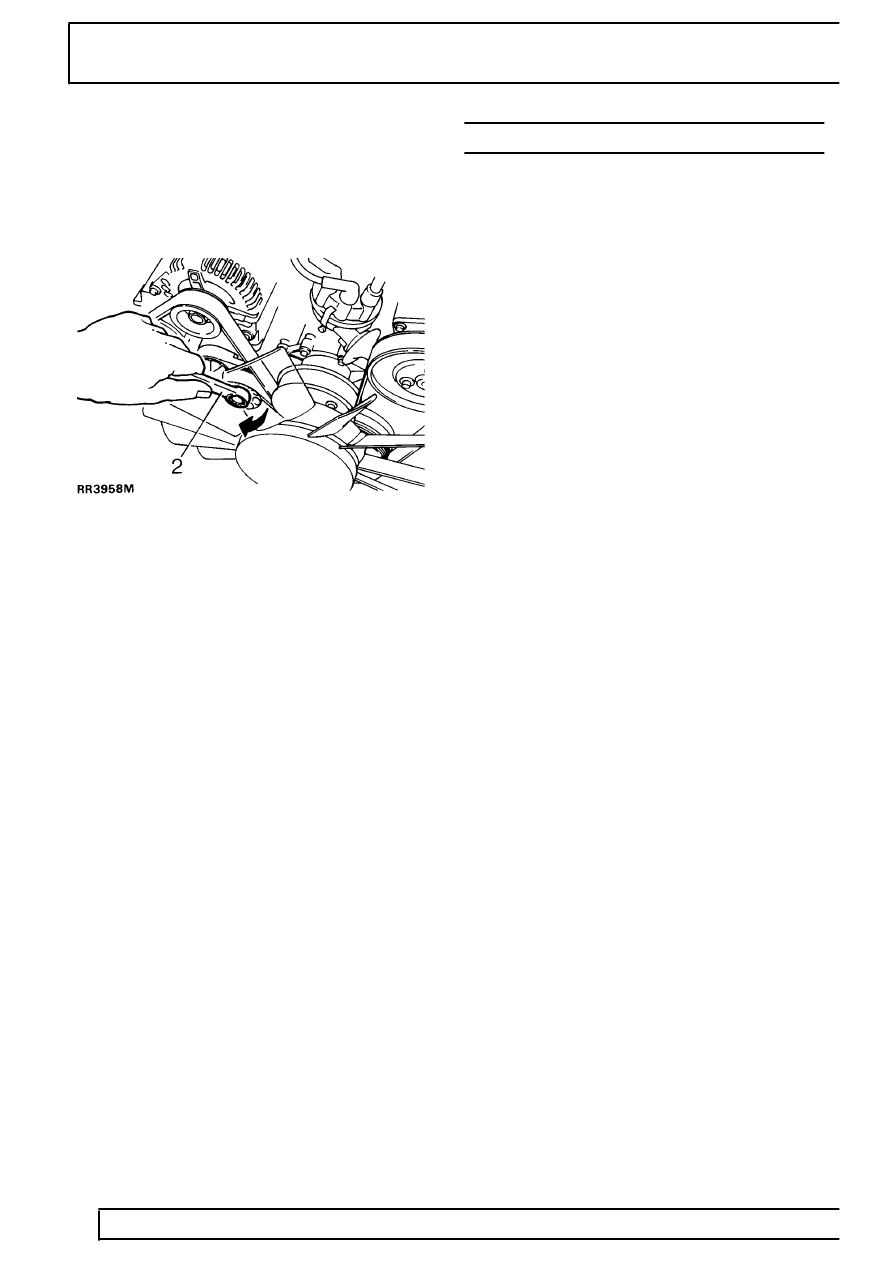

2. Release drive belt tension by turning tensioner

clockwise.

3. With tension released, remove belt from

generator pulley.

4. Release tensioner pulley.

5. Remove drive belt. Mark direction of rotation on

belt if refitting

Refit

6. Clean drive belt pulley grooves and ensure

grooves are not damaged.

7. Position belt correctly around all pulleys except

generator. Illustrations RR3956 and RR3957

show correct drive belt run.

8. Turn drive belt tensioner clockwise.

9. Locate drive belt on generator pulley.

10. Ensure drive belt is squarely located on pulleys

with all grooves engaged.

11. Release tensioner to tension drive belt.

12. Fit upper fan cowl section.

DRIVE BELT - CHECK TENSION

As the drive belt is automatically tensioned, no tension

check or adjustment should be necessary. If the drive

belt is believed to be slack carry out the following

checks:

1. Visually check drive belt tension.

2. Watch movement of tensioner with engine

running, 5 mm ’bounce’ is normal. If tensioner

movement is 12 mm or more, fit a new tensioner.

See Drive Belt Tensioner

3. Inspect tensioner. Is the tensioner arm and

spring case in contact? If so fit a new tensioner.

4. Using a recognised drive belt tensioning gauge,

check belt tension several times, running engine

between checks. The checks should be made at

the same point on the belt, away from the

tensioner.

Drive belt tension, with used tensioner and used drive

belt should be more than:-

270N. Non air conditioning or

295N with air conditioning.