300Tdi Discovery

REAR AXLE AND FINAL DRIVE

3

OVERHAUL

23. Check gear for freedom of rotation and backlash.

Nominal backlash should be present. Excess

backlash necessitates replacement of gears or

differential housing.

24. Check serial number marked on pinion end face

matches that on crown wheel.

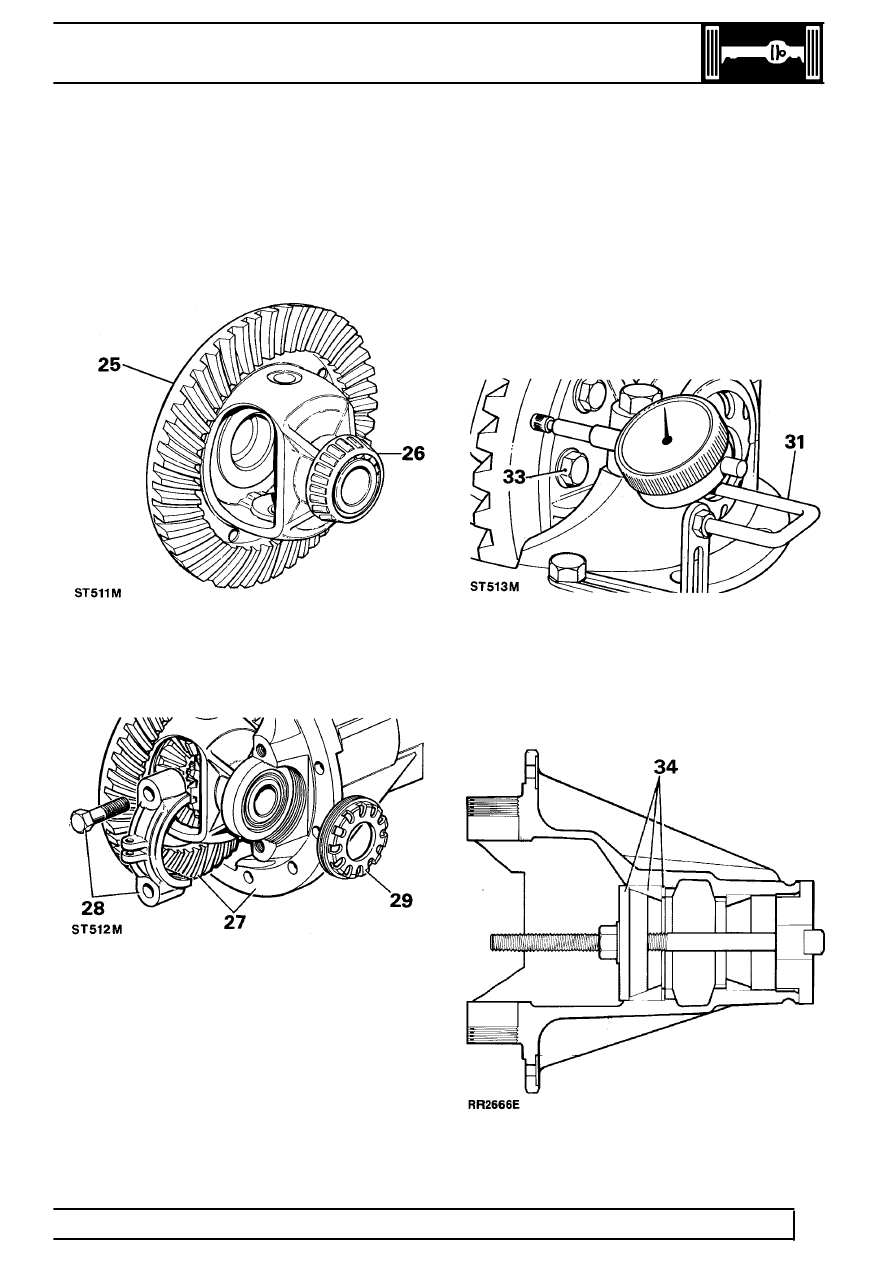

25. Clean and fit crown wheel.

26. Fit carrier bearings and assemble tracks to

bearings.

27. Place differential housing with crown wheel and

bearings in pinion housing.

28. Fit bearing caps and bolts. Do not tighten bolts.

29. Fit bearing adjusting nuts and adjust to obtain

zero end float.

30. Tighten bearing cap bolts to

90 Nm.

31. Check crown wheel for run-out. This should not

exceed 0,10 mm. If exceeded examine crown

wheel and mounting flange for burrs, grit, etc.

Refit and recheck. A buckled or damaged

differential housing flange is corrected by

replacing differential gear housing.

32. After checking run out remove differential

housing from pinion housing.

33. Remove crown wheel bolts and refit using

Loctite ’Studlock’. Tighten to

58 Nm.

34. Fit pinion head bearing track and original shim to

pinion housing. Use service tools LRT-54-505

and LRT-54-506. If fitting a new shim use

minimum 1.27 mm thickness.