300Tdi Discovery

57

STEERING

4

OVERHAUL

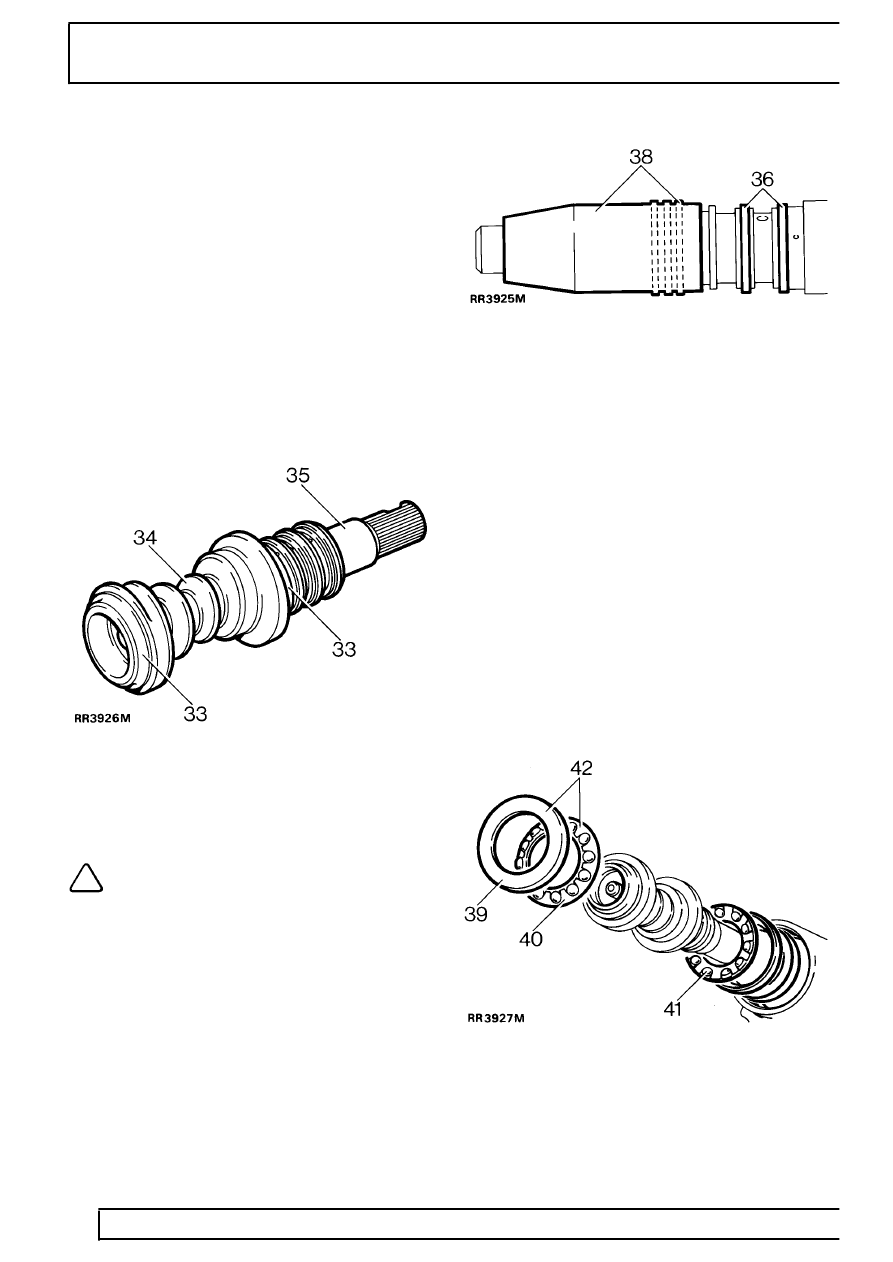

Sector shaft cover assembly

31. Inspect cover and bearing. If worn or damaged,

replacement parts are not available, fit a new

steering box.

Sector shaft adjuster locknut

32. The locknut is also a fluid seal. Fit new nut at

overhaul.

Valve and worm assembly

33. Examine bearing areas for wear. The areas must

be smooth and not indented.

34. Examine worm track which must be smooth and

not indented.

35. Check for wear on torsion bar assembly pin. No

free movement should exist between input shaft

and torsion bar or between torsion bar and

worm.

NOTE: Any sign of wear makes it essential

to fit new valve and worm assembly.

36. Examine valve rings for cuts, scratches and

grooves. The valve rings should be free to rotate

in grooves.

37. If required, replace all three rings, using ring

expander LRT-57-019. The expander will not

pass over rings already fitted. Remove rings to

allow access without damaging seal grooves.

38. Warm rings and expander tool to aid assembly.

Fit rings to expander, slide expander over valve

and worm assembly. In turn fit rings to their

grooves. Remove expander, slide valve and

worm assembly into ring compressor

LRT-57-020 and allow to cool.

Ball bearing and cage assemblies

39. Examine ball races and cups for wear and

general condition.

40. If ball cage has worn against bearing cup, fit

replacements.

41. Bearing balls must be retained by cage.

42. Bearing and cage repair is carried out by

complete replacement of assembly.