300Tdi Discovery

57

STEERING

8

OVERHAUL

83. Hold input shaft and rock drop arm to establish

backlash is present. Continue rocking and slowly

turn sector shaft adjusting screw clockwise.

Continue rotating adjuster screw until backlash

has almost been eliminated.

84. Refit locknut and tighten.

NOTE: It is important steering box is

centralised before any adjustments are

made.

85. Check maximum rolling torque one and a quarter

turns either side of centre position, using a

torque wrench and spline socket LRT-57-025.

Rotate adjuster screw to obtain across centre

torque of 0.34 Nm plus torque figure at one and

a quarter turns. Tighten adjuster locknut to

60

Nm.

Adjusting rack adjuster.

86. Turn in rack adjuster to increase figure

measured in instruction 85. by 0.23 - 0.34 Nm.

The final figure may be less, but must not

exceed 1.35 Nm.

87. Lock rack adjuster in position with grub screw.

Tighten to

5 Nm.

Torque peak check

With input shaft rotated from lock to lock, rolling

torque figures should be greatest across centre

position and equally disposed about centre position.

The condition depends on value of shimming fitted

between valve and worm assembly inner bearing cup

and casing. The original shim washer value will give

correct torque peak position unless major components

have been replaced.

Procedure

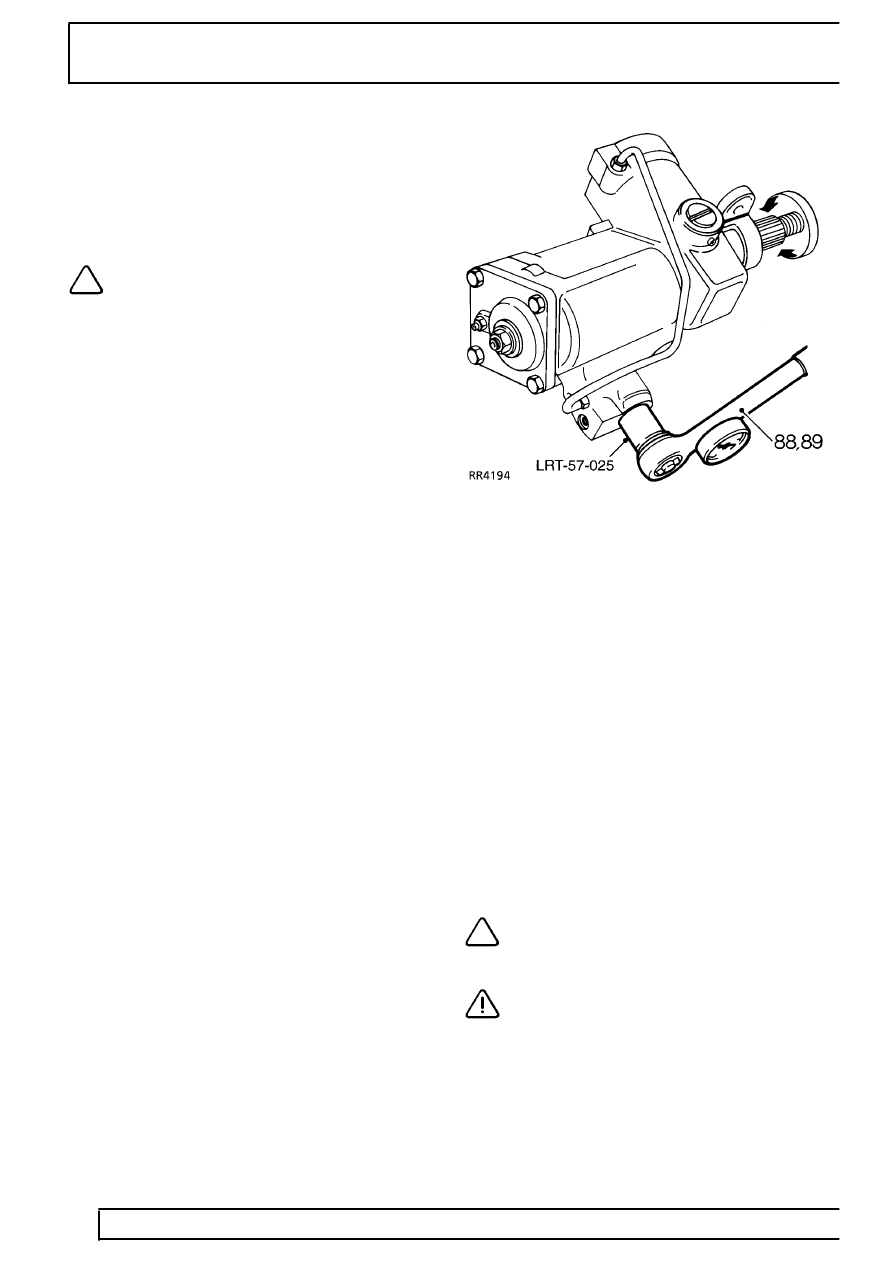

88. With input coupling shaft toward the operator,

turn shaft fully counter-clockwise.

89. Check torque figures obtained from lock to lock

using torque wrench and spline socket

LRT-57-025.

90. Check also for equal engagement either side of

centre.

Adjustments

91. Note where greatest figures are recorded

relative to steering position.If greatest figures are

not recorded across centre of travel (steering

straight-ahead), adjust as follows:

If torque peak occurs before centre position, add to

shim washer value; if torque peak occurs after centre

position, subtract from shim washer value,

refer to

fitting valve and worm assembly .

Shim washers are available as follows:

0.03mm, 0.07mm, 0.12mm and 0.24mm.

NOTE: Adjustment of 0.07mm to shim

value will move torque peak area by 1/4

turn on the shaft.

CAUTION: When reshimming valve and

worm, extreme caution must be exercised

to prevent seal damage during

reassembly.