Freelander System Description and Operation

EMISSION CONTROL - K SERIES KV6

DESCRIPTION AND OPERATION

17-3-7

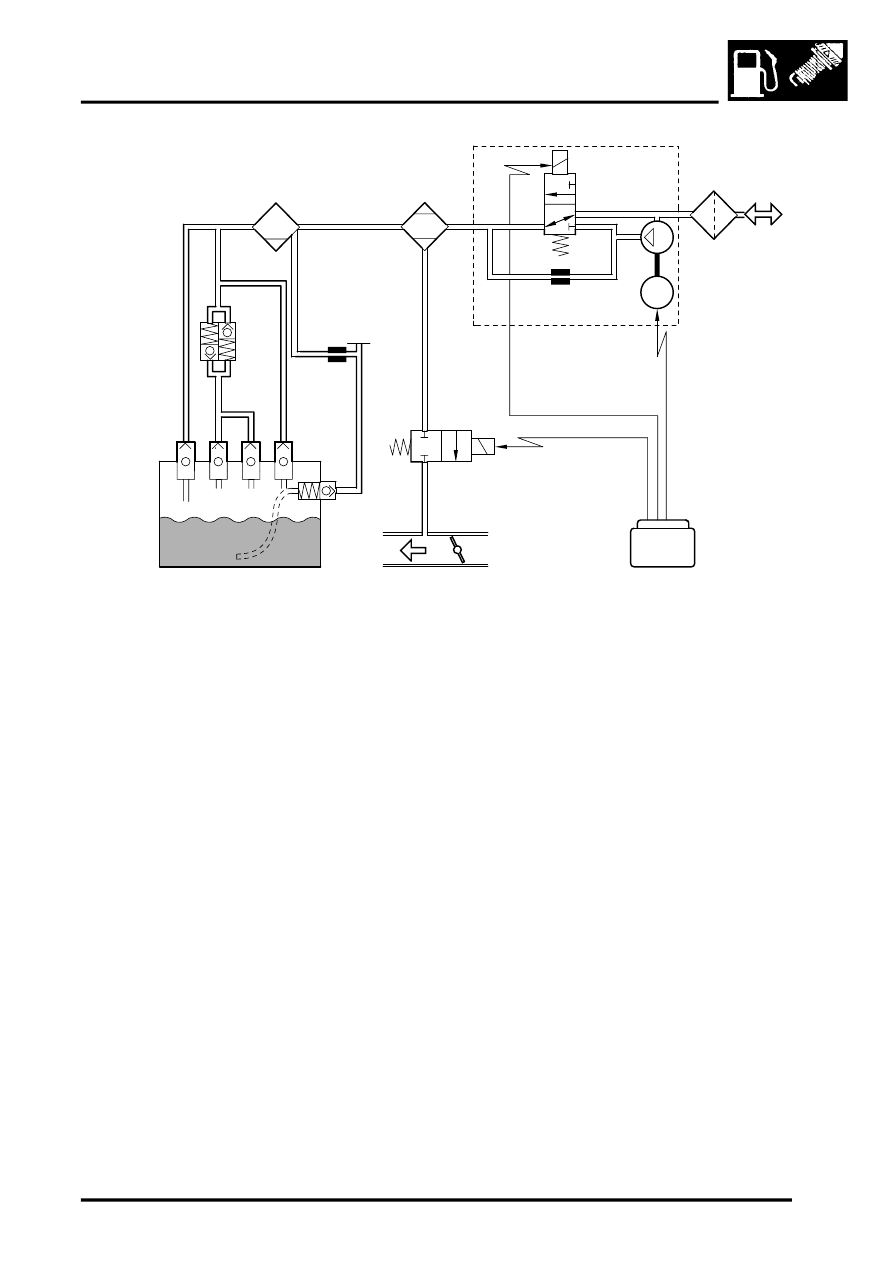

EVAP System Schematic – Vehicles from 2002.5 Model Year

1 Vapour separator

2 EVAP canister

3 DMTL

4 Change-over valve

5 0.5 mm (0.020 in) reference orifice

6 Air pump and motor

7 Air filter

8 ECM

9 Throttle body

10 Purge valve

11 Flap valve

12 Fuel tank

13 Roll over valve

14 ORVR valve

15 Two-way valve

16 Restrictor

17 Fuel filler cap

18 Filler tube

19 Fabric sleeve

Two-way Valve

The two-way valve limits the pressure and depression in the fuel tank and, during refuelling, induces automatic cut-

off in the refuelling nozzle when the fuel in the tank reaches the full level. The two-way valve is installed in the vent

pipe from the tank, next to the fuel pump assembly.

The two-way valve is a normally closed valve that opens, to release pressure from the fuel tank, at 18 to 50 mbar (0.26

and 0.73 lbf/in

2

). Air is allowed to flow back into the fuel tank, as the pressure in the tank decreases, through a non

return valve within the body of the two-way valve. The nominal opening pressure of the non return valve is 1 mbar

(0.015 lbf/in

2

).

During refuelling, if the fuel in the tank reaches the full level outward venting becomes restricted, which creates a back

pressure in the filler tube and automatically closes the refuelling nozzle. The restriction is caused by the fuel closing

the ORVR valve.

18

15

14

13

13

13

4

M17 0362

1

2

3

16

17

12

11

10

9

8

7

6

1

5

M

19