Range Rover Automatic Transmission Valve Block and Solenoid Valves Description

AUTOMATIC TRANSMISSION – ZF 5HP24

DESCRIPTION AND OPERATION 44-2-17

Solenoid EPRS1 supplies a lower control pressure as the signal amperage increases. The EPRS1 solenoid is a

normally closed regulating flow solenoid valve and regulates the main line pressure. The solenoid is used for adaptive

pressure control. The EAT ECU operates the solenoid using PWM signals. The EAT ECU monitors engine load and

clutch slip and varies the solenoid duty cycle accordingly.

Solenoids EPRS2, 3 and 5 supply a higher control pressure as the signal amperage increases. The solenoids are

normally open solenoids regulating flow solenoid valves. The solenoids are used to regulate the supply of fluid

pressure for clutch application during overlap up and down shifts of gears 2–3, 3–4 and 4–5. The EAT ECU operates

the solenoids using a PWM earth proportional to the required increasing or decreasing clutch pressures.

The resistance of the coil winding for solenoid EPRS1 is between 5.4 to 6.4

Ω

at 20

°

C (68

°

F). The resistance of the

coil windings for solenoids EPRS2, 3, 4 and 5 is between 5.9 and 6.9

Ω

at 20

°

C (68

°

F).

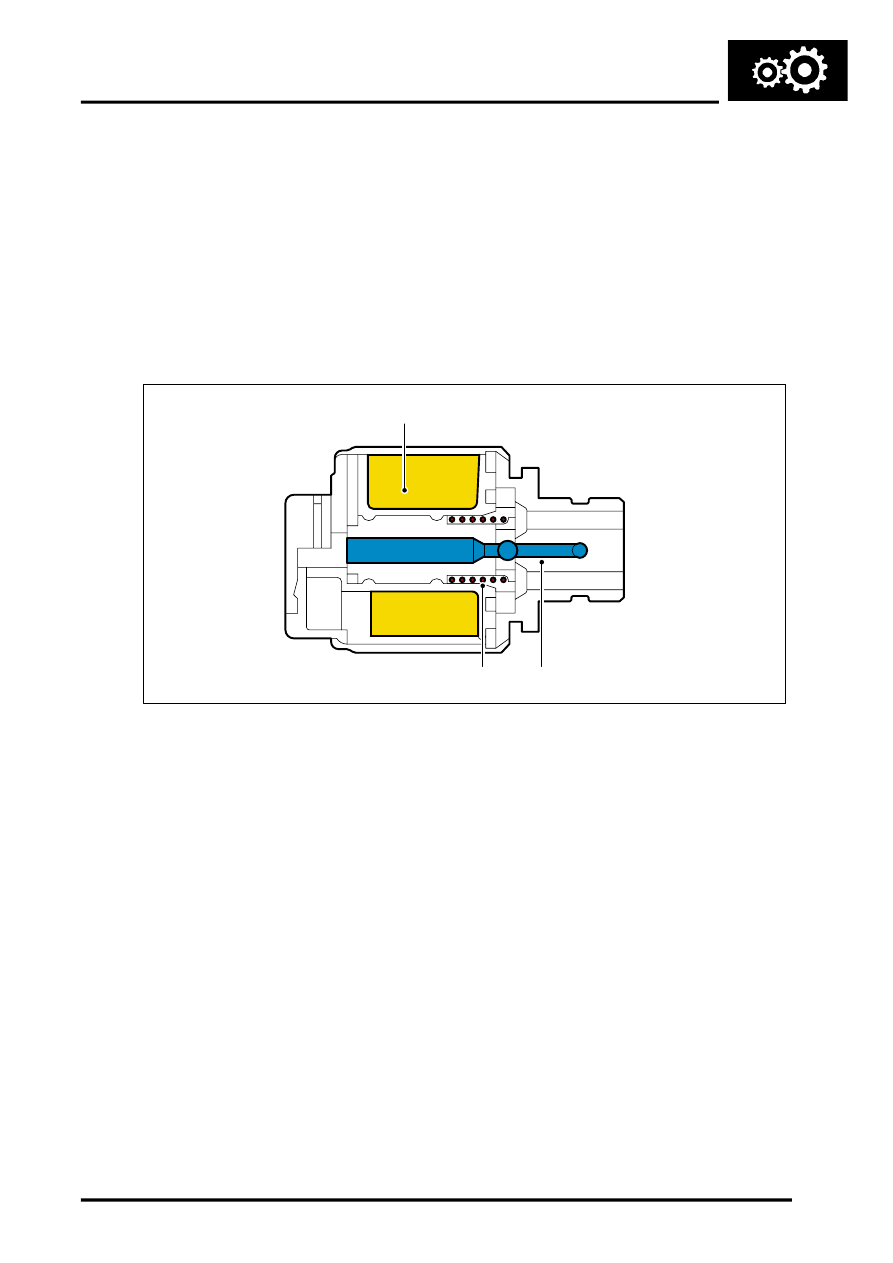

Shift Control Solenoids

1 Coil winding

2 Valve

3 Spring

Three shift control Solenoid Valves (SV) are located in the valve block. The solenoids are controlled by the EAT ECU

and convert electrical signals into hydraulic control signals to control clutch application.

The shift control solenoids SV1, 2 and 3 are normally closed, on/off solenoids which are controlled by the EAT ECU

switching the solenoid to earth. The EAT ECU also supplies the power to solenoids. The EAT ECU energises the

solenoids in a programmed sequence for clutch application for gear ratio changes and shift control.

The resistance of the coil winding for solenoids SV1, 2 and 3 is between 26 to 30.4

Ω

at 20

°

C (68

°

F).

Dampers

There are six dampers located in the valve block. Four of the dampers are used to regulate and dampen the regulated

pressure supplied via the pressure regulating solenoid valves. The two remaining dampers are used for operation of

clutches 'A' and 'C' and providing damping of the fluid pressure during shift changes. All of the dampers are load

dependent through modulation of the damper against its return spring pressure.

The dampers comprise a piston, a housing bore and a spring. The piston is subject to the pressure applied by the

spring. The bore has a connecting port to the function to which it applies. Fluid pressure applied to the applicable

component (i.e. a clutch) is also subjected to the full area of the piston, which moves against the opposing force

applied by the spring. The movement of the piston creates an action similar to a shock absorber, momentarily delaying

the build up of pressure in the circuit. This results in a more gradual application of clutches improving shift quality.

M44 1826

1

2

3