Range Rover L322 Transfer Box Description and Operation - Page 150

TRANSFER BOX

41-10

DESCRIPTION AND OPERATION

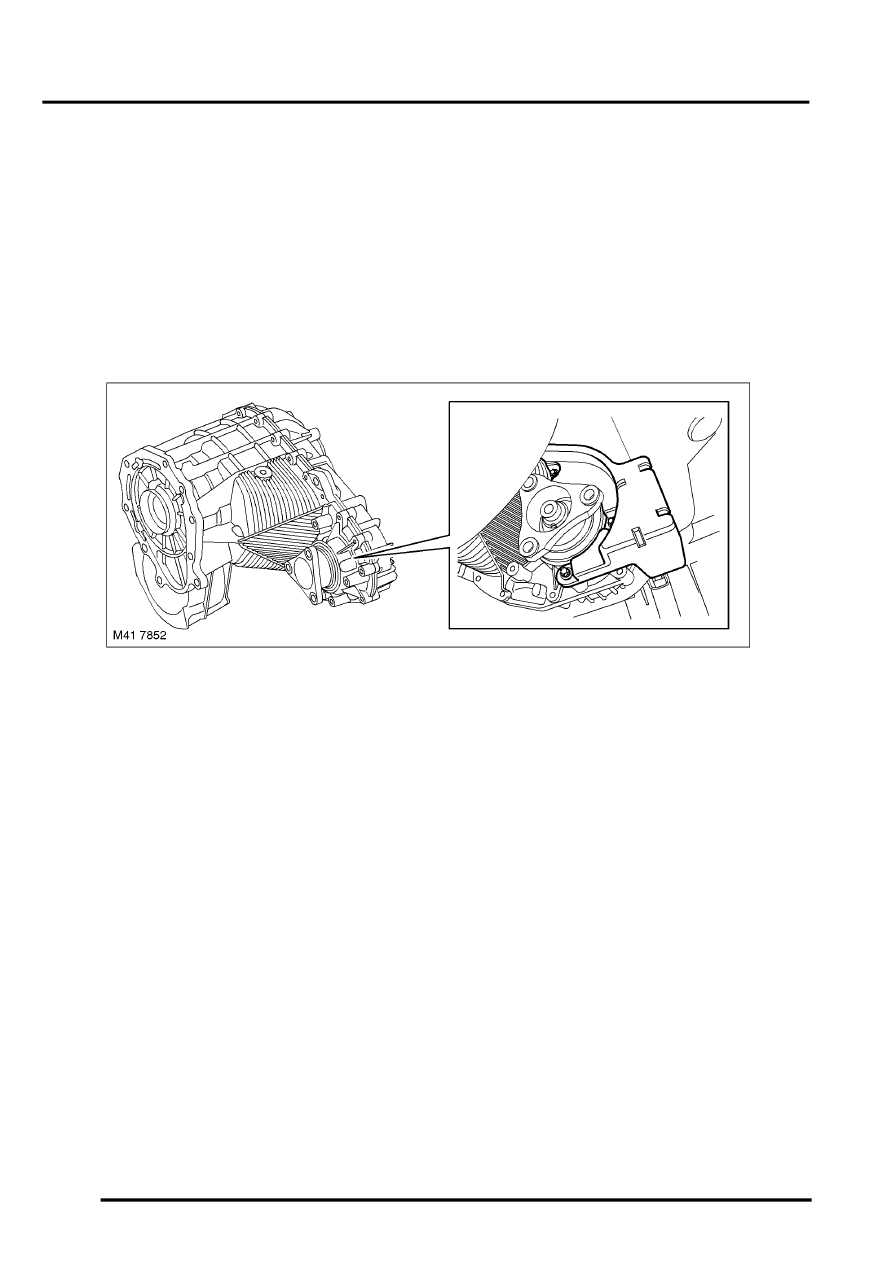

The major components of the transfer box are; the front casing assembly, the rear casing assembly, the planetary

gearset, the Torsen® differential, the fork and rail assembly and the actuator assembly.

The front and rear casing assemblies are manufactured from cast aluminium. Fins are cast into the front casing to aid

heat dissipation. Both casing assemblies are bolted together and provide the bearing locations for the main shaft, the

Torsen® differential and the planetary gearset. The rear casing provides the attachment location for the actuator

assembly.

An oil pump assembly is located in the rear casing and is driven by a splined coupling on the main shaft. The pump

has an oil tube to the bottom of the two casings with a filter screen to collect particulate matter. A magnet is located

below the filter screen to collect any metallic particulate matter. The oil pump provides a pressurised supply to a drilling

in the centre of the main shaft. Cross-drillings in the main shaft provide lubrication for the bearings and rotary

components.

Mass Damper (Td6 models only)

On Td6 engine models, a mass damper is fitted to the front casing assembly. The damper is located next to the front

output flange and secured to the casing with bolts. The damper absorbs vibration and resonance inherent with diesel

engines, reducing passenger compartment noise and vibration.

The front casing assembly houses a mounting bush which differs in its material between engine variants. The bushes

are identified by a colour code; red is for V8 engine models and blue is for Td6 engine models. The construction of

the bushes is visually identical. The material from which the bushes are constructed differs to absorb the differing

vibrational frequencies between the engine variants.

Drive is passed from the input shaft and via the Torsen® differential to the mainshaft and the drive sprocket assembly.

The mainshaft rotates and passes the rotational motion to the rear propshaft. The drive sprocket assembly rotates

and passes this rotation, via the chain, to the front propshaft. The drive sprocket carries a 3/8” pitch drive chain which

drives a sprocket which is integral with the front output shaft. Because both sprockets are the same, with the same

number of drive teeth, the rotational motion of the drive sprocket is identical to that of the front output shaft sprocket.

The 50:50 torque output ratio is produced from the Torsen® differential unit. This unit can drive the output to the main

shaft and the drive sprocket assembly at a 50:50 ratio during normal driving conditions.

The transfer box requires a unique oil developed with NVG and Burmah-Castrol specifically for the Land Rover

transfer box. The oil is a fully synthetic with the following specification: BOT 26 FMB 1 75W-90. The oil contains unique

additives which enhance the transfer box operation. No other oil must be used in the transfer box.

Should the transfer box require repair, the only serviceable items are the input and two output shaft seals, the drain

and filler plugs, the actuator and gearbox assembly and the breather tube. Any repairs beyond the items listed

requires a replacement transfer box.