L322 Range Rover Service Procedures

GENERAL INFORMATION

03-14

Flexible Pipes and Hoses

General

When removing and installing flexible hydraulic pipes

and hoses, ensure that the following practices are

observed to ensure component serviceability.

l

Before removing any brake or power steering

hose, clean end fittings and area surrounding

them as thoroughly as possible.

l

Obtain appropriate plugs or caps before

detaching hose end fittings, so that the ports can

be immediately covered to prevent the ingress

of dirt.

l

Clean hose externally and blow through with

airline. Examine carefully for cracks, separation

of plies, security of end fittings and external

damage. Reject any faulty hoses.

l

When refitting a hose, ensure that no

unnecessary bends are introduced, and that

hose is not twisted before or during tightening of

union nuts.

l

Fit a cap to seal a hydraulic union and a plug to

its socket after removal to prevent ingress of

dirt.

l

Absolute cleanliness must be observed with

hydraulic components at all times.

l

After any work on hydraulic systems, carefully

inspect for leaks underneath the vehicle while a

second operator applies maximum brake

pressure to the brakes (engine running) and

operates the steering.

Fuel system hoses

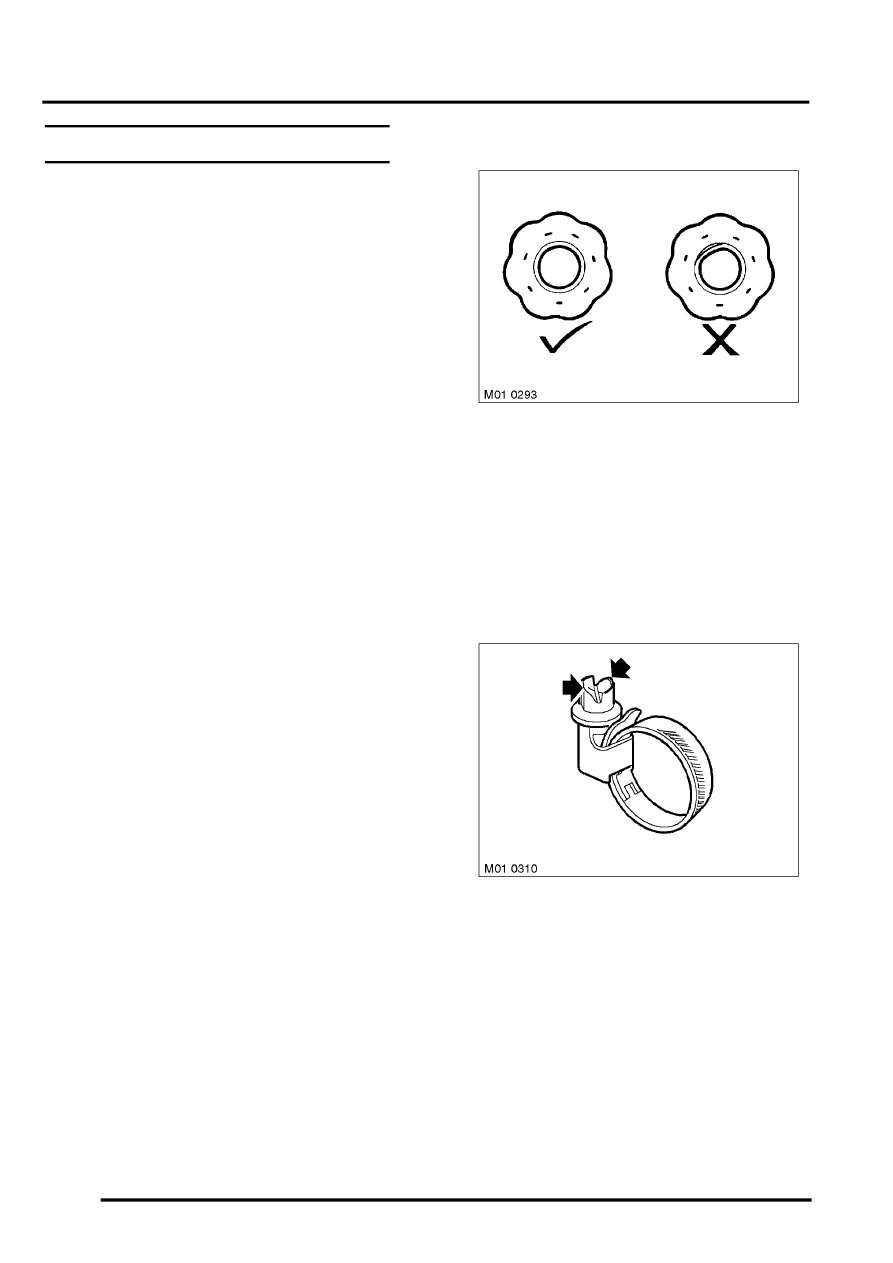

All fuel hoses are made up of two laminations, an

armoured rubber outer sleeve and an inner viton

core. If any of the fuel system hoses have been

disconnected, it is imperative that the internal bore is

inspected to ensure that the viton lining has not

become separated from the armoured outer sleeve.

A new hose must be fitted if separation is evident.

Fuel system hose clips

Certain fuel system hoses are of the 'break-off head'

type, where a portion of the slot in the screw head

shears off when the clip is tightened to a pre-

determined torque. These clips may be removed

using a screwdriver and must be replaced with a new

clip of the same type. Clips must be tightened until

the portion of the slot shears off. Do not attempt to

tighten clips by any other method.