L322 Range Rover Service Procedures

GENERAL INFORMATION

03-9

l

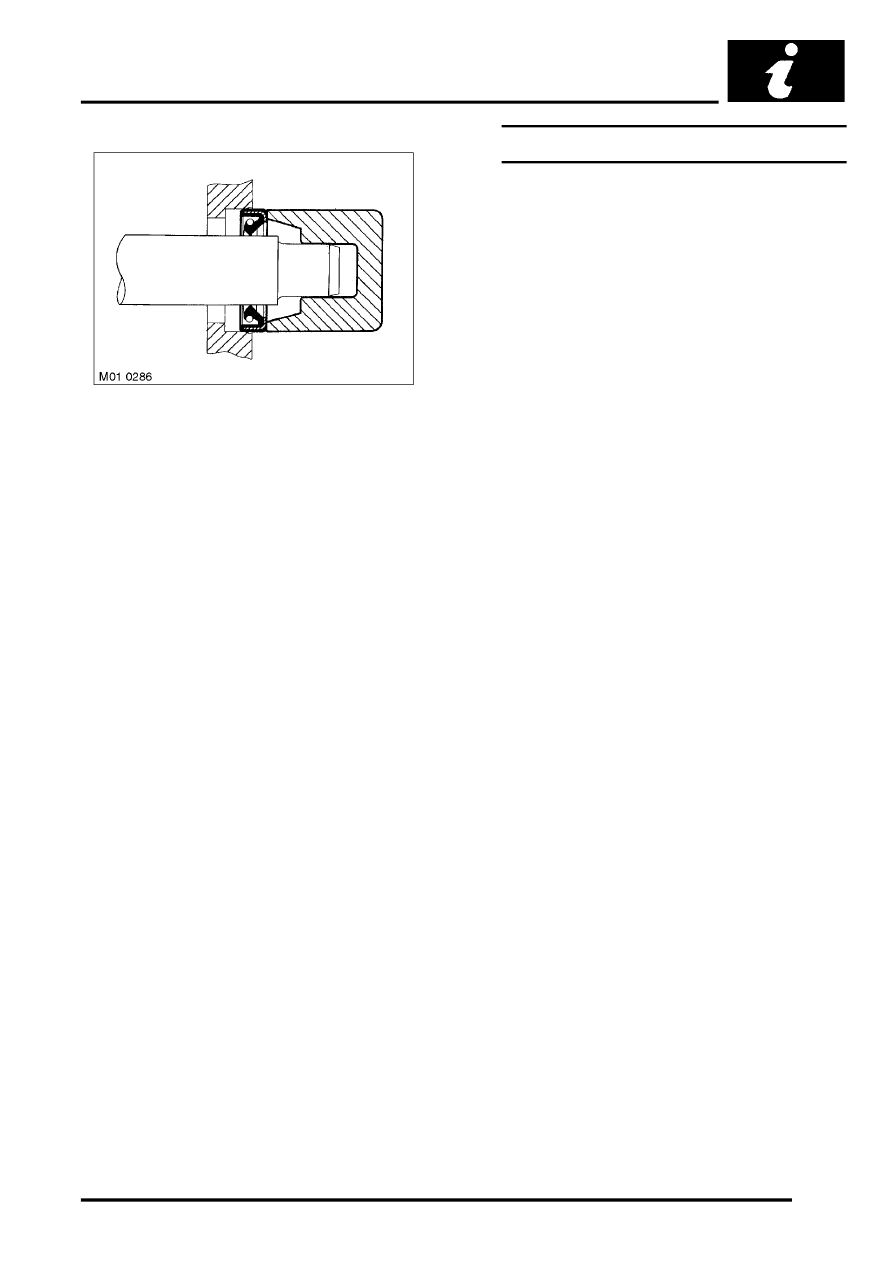

Use the recommended service tool to fit an oil

seal. If the correct service tool is not available,

use a suitable tube approximately 0.4 mm

(0.015 in.) smaller than the outside diameter of

the seal. Use a hammer VERY GENTLY on

drift, if a suitable press is not available.

l

Press or drift the seal in to the depth of its

housing with the sealing lip facing the lubricant

to be retained if the housing is shouldered, or

flush with the face of the housing where no

shoulder is provided. Ensure that the seal does

not enter the housing in a tilted position.

Joints and Joint Faces

General

Fit joints dry unless specified otherwise.

l

Always use the correct gaskets as specified.

l

When jointing compound is used, apply in a thin

uniform film to metal surfaces; take care to

prevent jointing compound from entering

oilways, pipes or blind tapped holes.

l

If gaskets and/or jointing compound is

recommended for use; remove all traces of old

jointing material prior to reassembly. Do not use

a tool which will damage the joint faces and

smooth out any scratches or burrs using an oil

stone. Do not allow dirt or jointing material to

enter any tapped holes or enclosed parts.

l

Prior to reassembly, blow through any pipes,

channels or crevices with compressed air.