LR3/Disco 3

Tire Changing

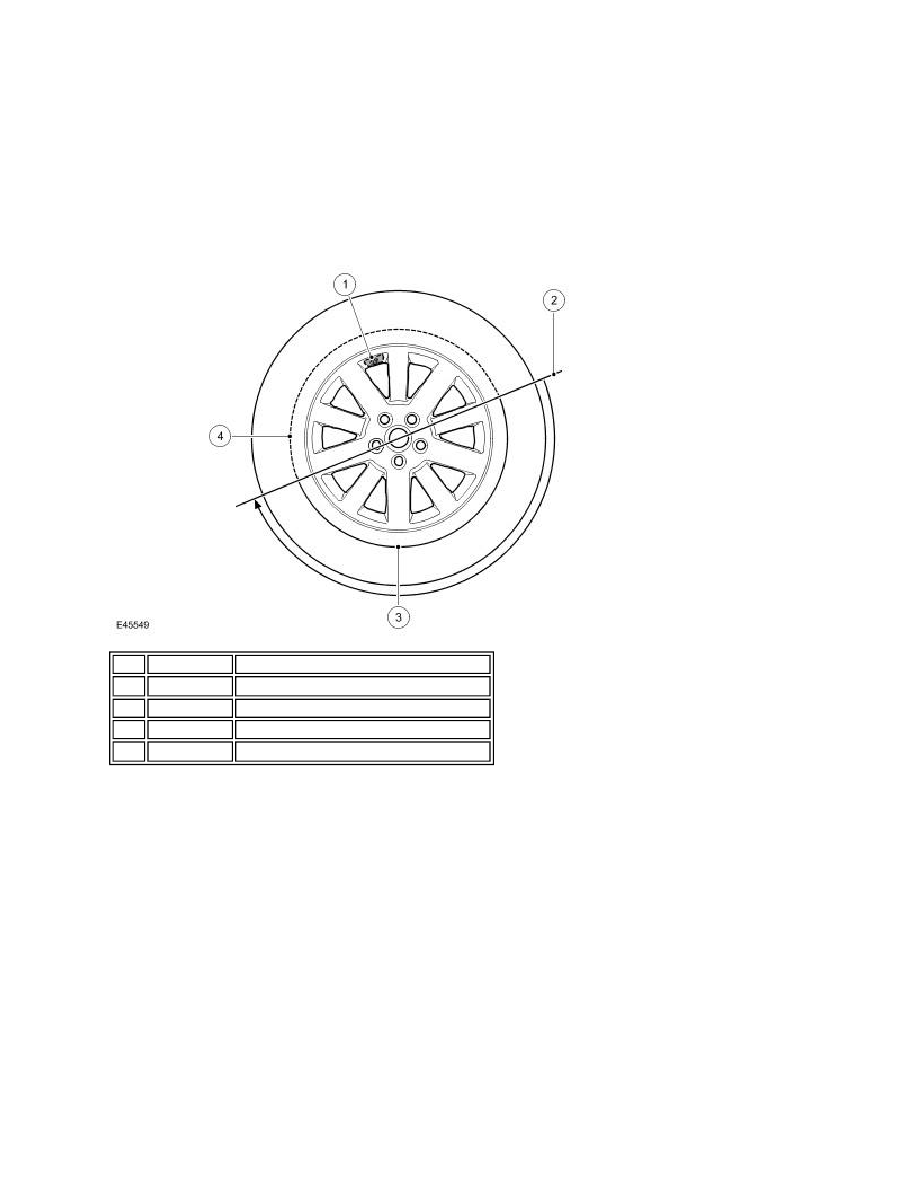

Care must be taken when removing and refitting tires to ensure that the tire pressure sensor is not damaged.

When removing the tire, the bead breaker must not be used within 90 degrees of the tire valve in each direction.

When using the tire removal machine, the fitting arm start position must be positioned as shown in the tire changing

illustration. The wheel can then be rotated through 180 degrees in a counterclockwise direction. This will relieve the high

tension from the tire bead allowing the remaining 180 degrees of the tire to be manually pulled from the rim.

When refitting the tire, position the fitting arm as shown. Rotate the tire and take care that the bead on the low tension

side of the tire does not damage the sensor.

Tread Act - NAS Only

Vehicles supplied to the North American markets must comply with the legislation of the Transport Recall Enhancement,

Accountability and Documentation (TREAD) act. Part of the requirement of the TREAD act is for the vehicle to display a

label, positioned on the driver's side B-pillar, which defines the recommended tire inflation pressure, load limits and

maximum load of passengers and luggage weight the vehicle can safely carry. This label will be specific to each individual

vehicle and will be installed on the production line.

This label must not be removed from the vehicle. The label information will only define the specification of the vehicle as it

came off the production line. It will not include dealer or owner fitted accessory wheels and tires of differing size from the

original fitment.

cold (ambient temperature). If the tires have been subjected to use or exposed to direct sunlight, move the vehicle

into a shaded position and allow the tires to cool before checking and/or adjusting the pressures.

Item Part Number

Description

1

-

Tire valve and pressure sensor

2

-

Tire fitting/removal tool initial start position

3

-

High tire and bead tension area

4

-

Low tire and bead tension area