LR3/Disco 3

The crankshaft is supported on four main bearings, with each pair of crankpins mutually offset by 30 degrees to give

equal firing intervals. Cast in Spheroidal Graphite (SG) iron, the crankshaft has cold rolled fillets on all journals, except the

outer mains, for toughness and failure resistance. The nine crankshaft counterweights increase smoothness and reduce

bearing wear by splitting the loads evenly across the bearings. Thrust washer halves at the top and bottom of number

three main bearing control end-float.

Oil grooves are provided in the upper and lower halves of all the main bearing shells to supply oil, via drillings in the

crankshaft, to the connecting rod big-end bearings.

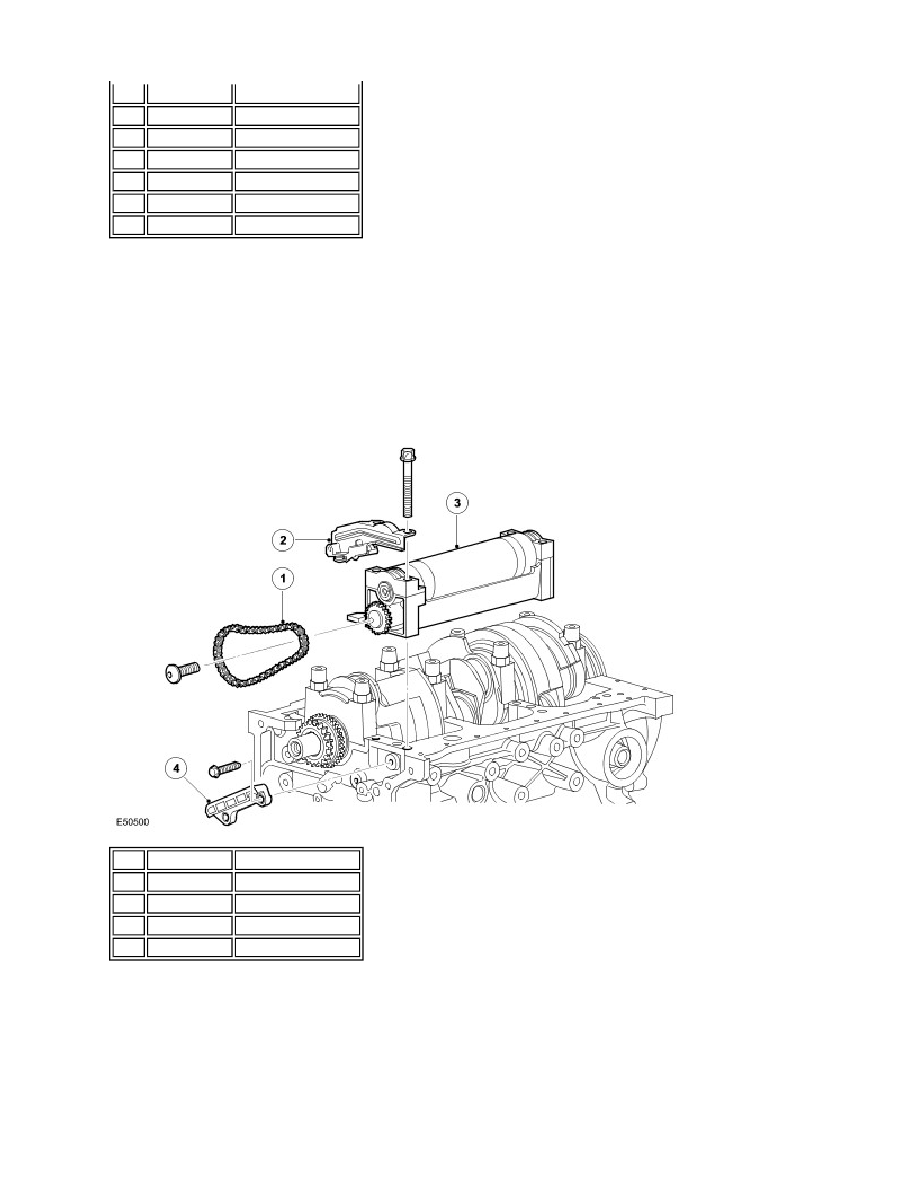

Balance Shaft Assembly

A 60 degree V6 is often thought of inherently balanced, because its first-order forces can be compensated by crankshaft

counter-weighting. However, the V6 4.0L engine generates a second-order unbalanced at twice the crank speed.

To achieve the desired smoothness, the V6 4.0L engine includes a unique counter-rotating balance shaft, which is chain

driven by the crankshaft and runs at twice engine speed. The shaft produces an opposite second-order force, which

cancels the inherent unbalance.

Since the balance shaft is positioned on the bottom the cylinder block, on the RH side and is secured by 4 bolts. Because

Item Part Number

Description

1

-

Main bearing cap

2

-

Main bearing, lower

3

-

Key

4

-

Crankshaft

5

-

Main bearing, upper

6

-

Main bearing, thrust

Item Part Number

Description

1

-

Drive chain

2

-

Tensioner assembly

3

-

Balance assembly

4

-

Chain guide