LR3/Disco 3

The connecting rods are manufactured from sinter-forged steel and have fracture-split bearing caps. The bearing caps

are produced by fracturing the opposing sides of the connecting rod at the bearing horizontal centre line. As well as being

easier to manufacture, when reassembled the fractured surfaces interlock to form a strong seamless joint. The cylinder

position is marked on adjoining sides of the joint to identify matching connecting rods and bearing caps. The connecting

rod bearings are aluminium/tin split plain bearings.

The pistons are of the open-ended skirt design. Three piston rings, two compression and one oil control, are installed on

each piston. Each piston is installed on a gudgeon pin located in a aluminium/tin bushing in the connecting rod.

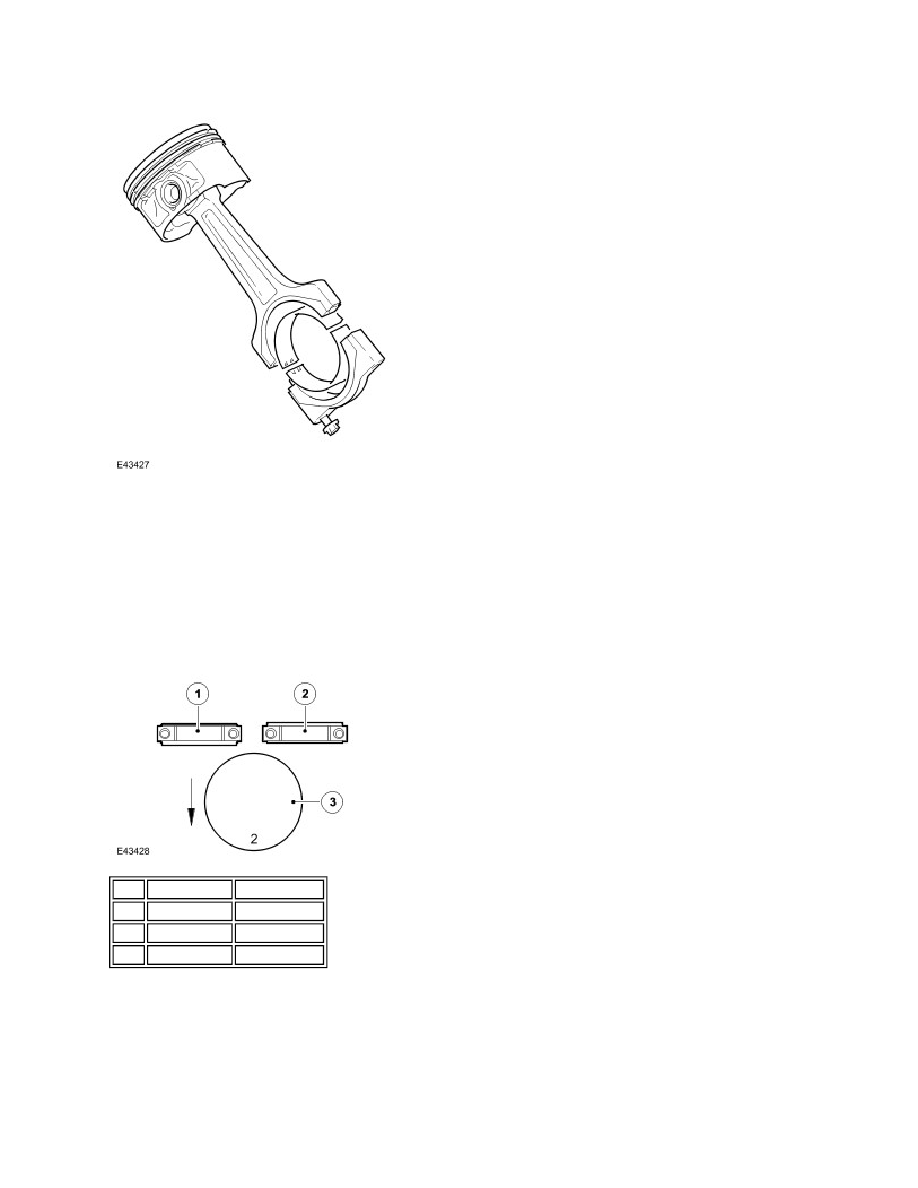

Connecting Rod and Piston Installation

The piston grade number is stamped on the crown of the piston and must coincide with that for each cylinder bore. The

piston must be assembled in the correct orientation for the designated cylinder bore:

Bank 'A' - piston grade number and the thick flange of the connecting rod must face the front of the engine

Bank 'B' - piston grade number and the thin flange of the connecting rod must face the front of the engine

Crankshaft Position Sensor

Item Part Number Description

1

-

Bank A (RHS)

2

-

Bank B (LHS)

3

-

Piston