LR3/Disco 3

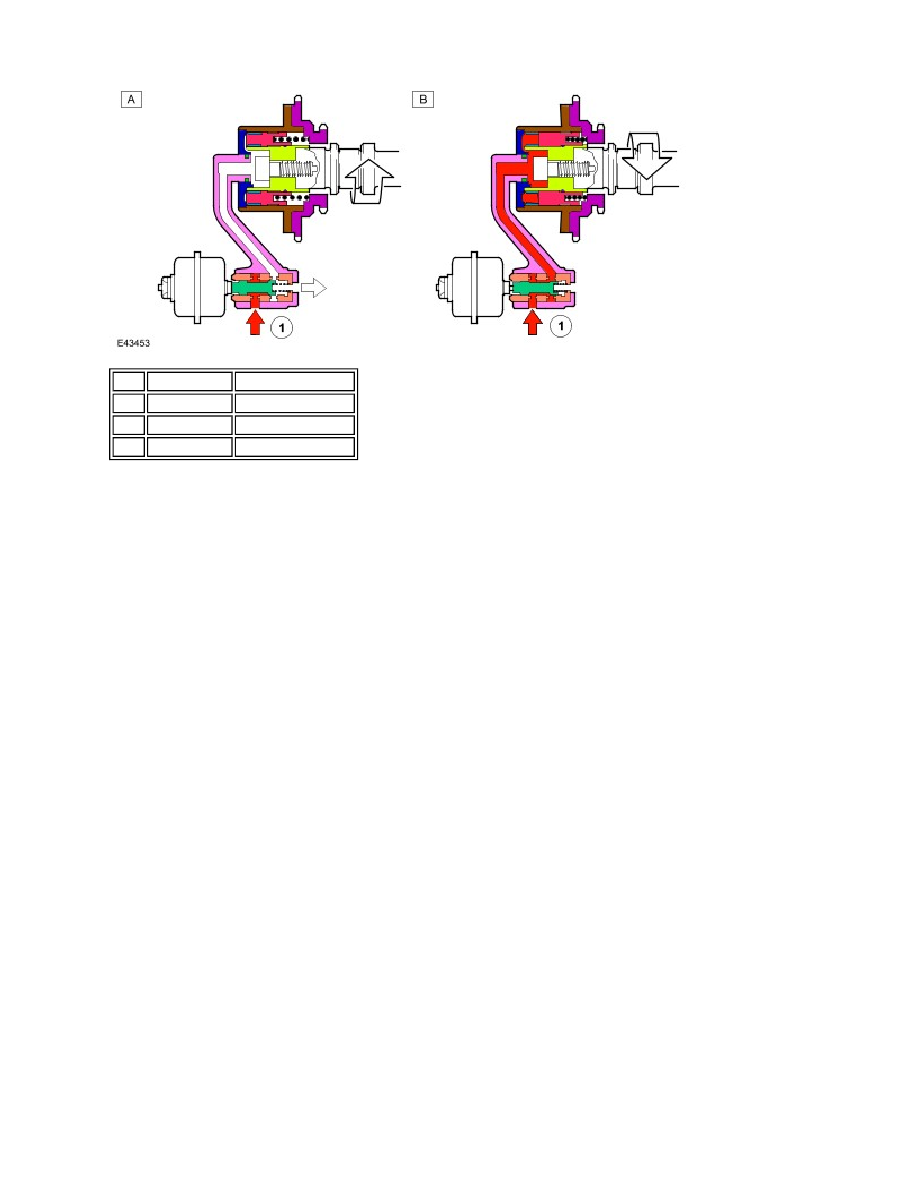

The VVT unit is a hydraulic actuator mounted on the end of the intake camshaft, which advances or retards the intake

camshaft timing and thereby alters the camshaft to crankshaft phasing. The oil control solenoid, controlled by the ECM,

routes oil pressure to either the advance or retard chambers located either side of the three vanes interspersed within the

machined housing of the unit.

The VVT unit is driven by the primary chain and rotates relative to the exhaust camshaft sprocket. When the ECM

requests the camshaft timing to advance, the oil control solenoid is energized moving the shuttle valve to the relevant

position to allow engine oil pressure, via a filter, into the VVT unit's advance chambers. When the camshaft timing is

requested to retard, the shuttle valve moves position to allow oil pressure to exit the advance chambers, while

simultaneously routing the oil pressure into the retard chambers.

When directed by the ECM, the VVT unit will be set to the optimum position between full advance and retard for a

particular engine speed and load. This is achieved when the ECM sends the energising signal to the oil control solenoid

until the target position is met. At this point, the energizing signal is reduced to hold the solenoid position, and as a result

the position of the shuttle valve. This function is under closed-loop control, where the ECM will assess any decrease in

shuttle-valve oil-pressure, via signals from the camshaft position sensor. The ECM will increase the energizing signal,

when required, to maintain the shuttle-valve hold position.

Engine oil properties and temperature can affect the ability of the VVT mechanism to follow demand changes to the cam

phase angle. At very low oil-temperatures, movement of the VVT mechanism is sluggish due to increased viscosity, and

at high oil-temperatures the reduced viscosity may impair operation if the oil pressure is too low. To maintain satisfactory

VVT performance, an increased capacity oil pump is installed, plus an engine oil temperature sensor to enable monitoring

by the ECM. The VVT system is normally under closed-loop control except in extreme temperature conditions, such as

cold starts below 0°C. At extremely high oil-temperatures, the ECM may limit the amount of VVT advance to prevent the

engine from stalling when returning to idle speed.

The VVT does not operate when engine oil-pressure is below 1.25 bar, as there is insufficient pressure to release the

VVT unit's internal stopper pin. This usually occurs when the engine is shutting-down and the VVT has returned to the

retarded position. The stopper pin locks the camshaft to the VVT unit to ensure camshaft stability during the next engine

start-up.

LUBRICATION SYSTEM

Item Part Number

Description

A

-

Retarded

B

-

Advanced

1

-

Engine oil pressure