LR3/Disco 3

The trigger wheel is located on the rear of the crankshaft. It is pressed onto the crankshaft using a special tool, which also

precisely aligns the trigger wheel for crankshaft position and timing. The trigger wheel consists of 60 magnets, minus 2 for

ECM crankshaft position reference and synchronisation. The magnets cannot be seen on the trigger-wheel; therefore, it

can only be positioned using the special tool.

The CKP sensor air gap is 0.4mm to 0.5mm there is no adjustment. The sensor bolts into the rear oil seal retainer and the

tolerance on the retainer and sensor gives an air gap within the specified range.

NOTE :

Main Bearings

The main bearings are aluminium/tin split plain selective bearings. An oil groove in the top half of each bearing transfers

oil into the crankshaft for lubrication of the connecting rod bearings. The upper and lower shells of bearing number four

contain integral thrust washers, which limits the end float of the crankshaft.

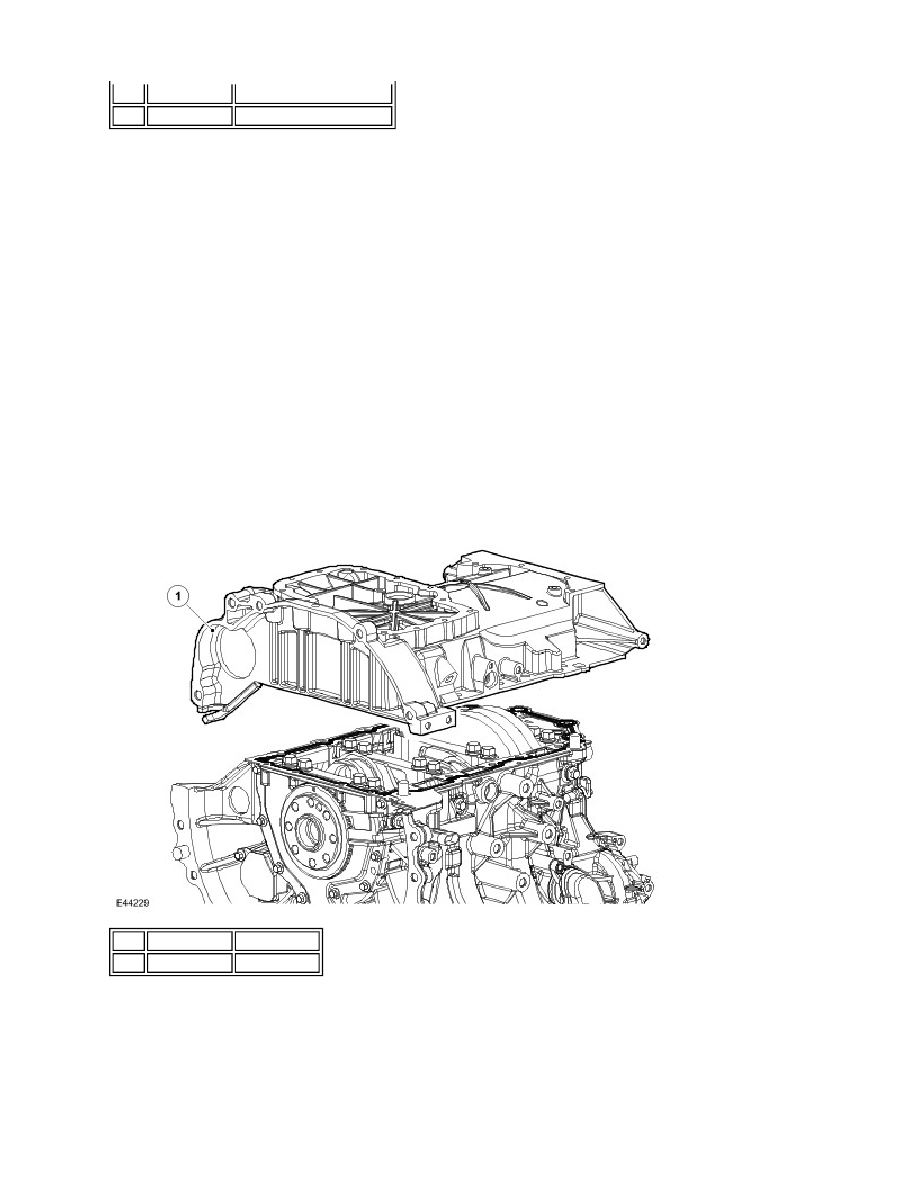

Ladder Frame

The ladder frame is fitted to the lower cylinder block to stiffen the base structure thus helping to reduce Noise, Vibration

and Harshness (NVH). The frame is made of high-pressure die cast aluminium and also incorporates an oil baffle plate to

reduce oil foaming and slosh.

The ladder frame is secured to the cylinder block with 2 dowels, 2 locator pins for the gasket and 18 retaining bolts; three

different lengths of bolts are used:

Item Part Number

Description

1

-

CKP sensor trigger wheel

If the trigger wheel is removed for any reason, a new trigger wheel must be fitted. Do not reuse the old trigger

wheel.

Item Part Number Description

1

-

Ladder frame