LR3/Disco 3

GENERAL

The cooling system employed is of the pressure relief by-pass type, which allows coolant to circulate around the engine

and the heater circuit while the thermostat main valve is closed. The primary function of the cooling system is to maintain

the engine within an optimum temperature range under changing ambient and engine operating conditions. Secondary

functions are to provide heating for the passenger compartment and cooling for the transmission fluid and engine oil.

The cooling system comprises:

A radiator

An intercooler

A passenger compartment heater matrix

Two fuel coolers

Two Exhaust Gas Recirculation (EGR) coolers

A Fuel Burning Heater (FBH) (Market dependant)

A coolant pump

A Pressure Relief Thermostat (PRT)

An expansion tank

An electro-viscous fan

Connecting hoses and pipes.

ENGINE COOLING SYSTEM

The coolant is circulated by a centrifugal type pump mounted on the front of the engine and driven by the ancillary drive

'polyvee' belt. The coolant pump circulates coolant around the cylinder block and cylinder heads via a chamber located in

the 'vee' of the engine. Some of the coolant flow is diverted through the integrated fuel and engine oil coolers. Having

passed through the engine and oil coolers, the coolant returns to the thermostat housing via the by-pass pipe. Coolant

also circulates through the EGR coolers to the heater matrix and returns to the engine side of the PRT.

On vehicles fitted with FBH, the coolant circulates through the EGR coolers to the FBH unit (whether active or not) and

then on to the heater matrix. The coolant then returns to the engine side of the PRT

The PRT housing contains a normal thermostat, which is positioned such that the wax's temperature is controlled by both

the coolant from the radiator and the bypass. This results in the thermostat being able to vary its opening temperature

dependant on ambient conditions. The PRT also contains a sprung loaded valve, which limits the amount flow using the

bypass. This means that the engine can run without coolant flowing through the bypass temporarily, to improve heater

performance.

The radiator is a cross flow type with an aluminium matrix and has a drain tap on the lower RH rear face. The lower

radiator mountings are located part way up the end tanks. The mountings are fitted with rubber bushes, which sit on the

upper chassis rails. The radiator upper is mounted by pins, which are pushed through rubber bushes mounted in the

Front End Carrier (FEC) above the radiator.

The intercooler is attached to the bottom of the radiator by two pins, which locate into fittings in the radiator end tanks.

The radiator top hose is connected to the PRT by the bypass hose and the bottom hose is directly connected to the outlet

side of the thermostat housing.

The expansion tank is fitted forward of the LH suspension turret in the engine compartment. The expansion tank allows

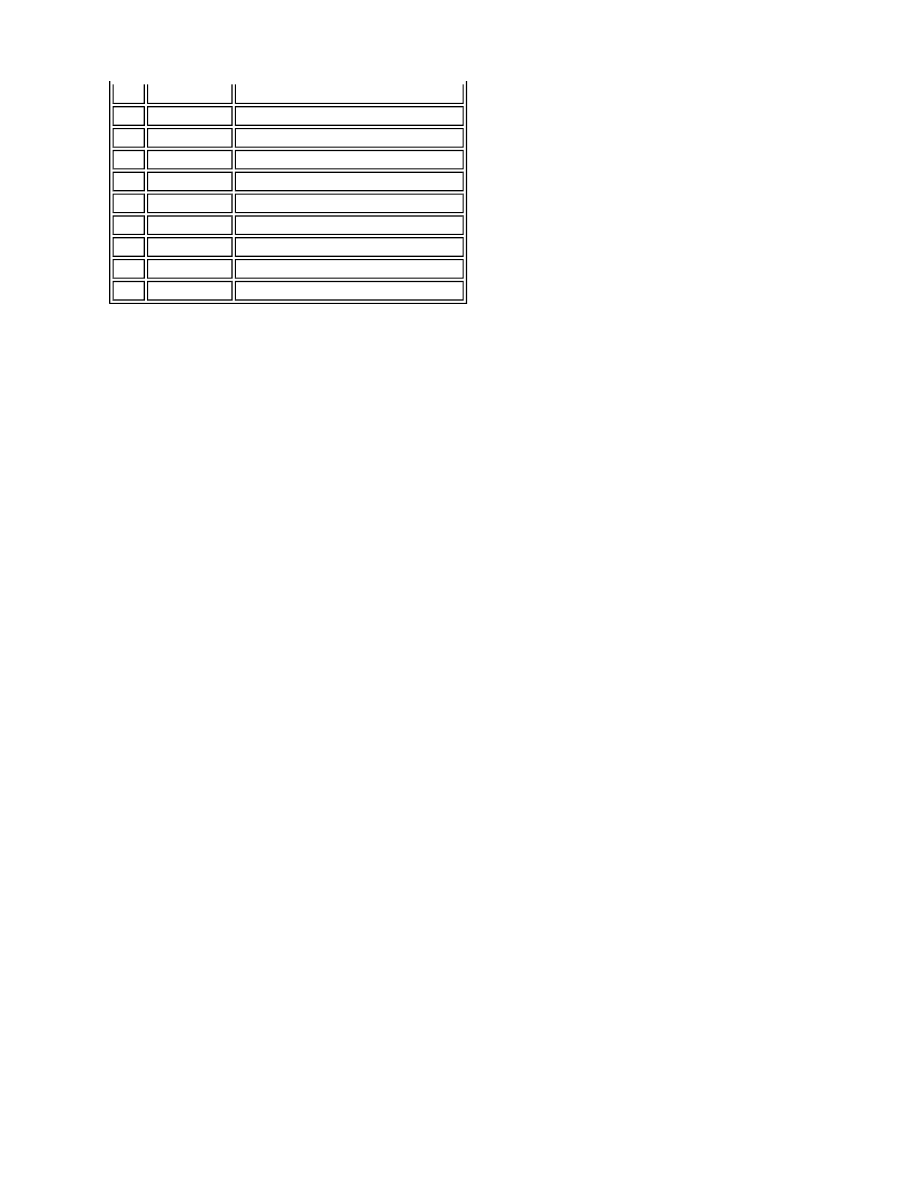

11

-

Hose, fuel cooler

12

-

Cooling fan

13

-

Hose, radiator to expansion tank

14

-

Shroud, lower

15

-

Radiator

16

-

Shroud, upper

17

-

Hose and thermostat assembly

18

-

Water pump

19

-

Water inlet connector

20

-

FBH hose, in and out