LR3/Disco 3

To meet increasing legislation in fuel evaporative loss the Evaporative Emissions Loss Control System has been

introduced to minimise the evaporative loss of fuel vapour from the fuel system to the atmosphere. This is achieved by

venting the fuel system through a vapour trap (charcoal cannister). The charcoal acts like a sponge and stores the vapour

until the canister is purged under the control of the ECM.

The charcoal canister is connected with the inlet manifold, after the throttle body, via a purge valve. This valve is opened

and closed according to a PWM signal from the ECM. The canister is purged by drawing clean air through the charcoal,

which carries the hydrocarbons into the engine where they are burnt. To maintain drivability and emission control purging

must be closely controlled as a 1% concentration of fuel vapour from the canister in the air intake may shift the air/fuel

ratio by as much as 20%. Purging must be carried out at regular intervals, to regenerate the charcoal, as its storage

capacity is limited, and is cycled with the Fuelling Adaption, as both cannot be active at the same time.

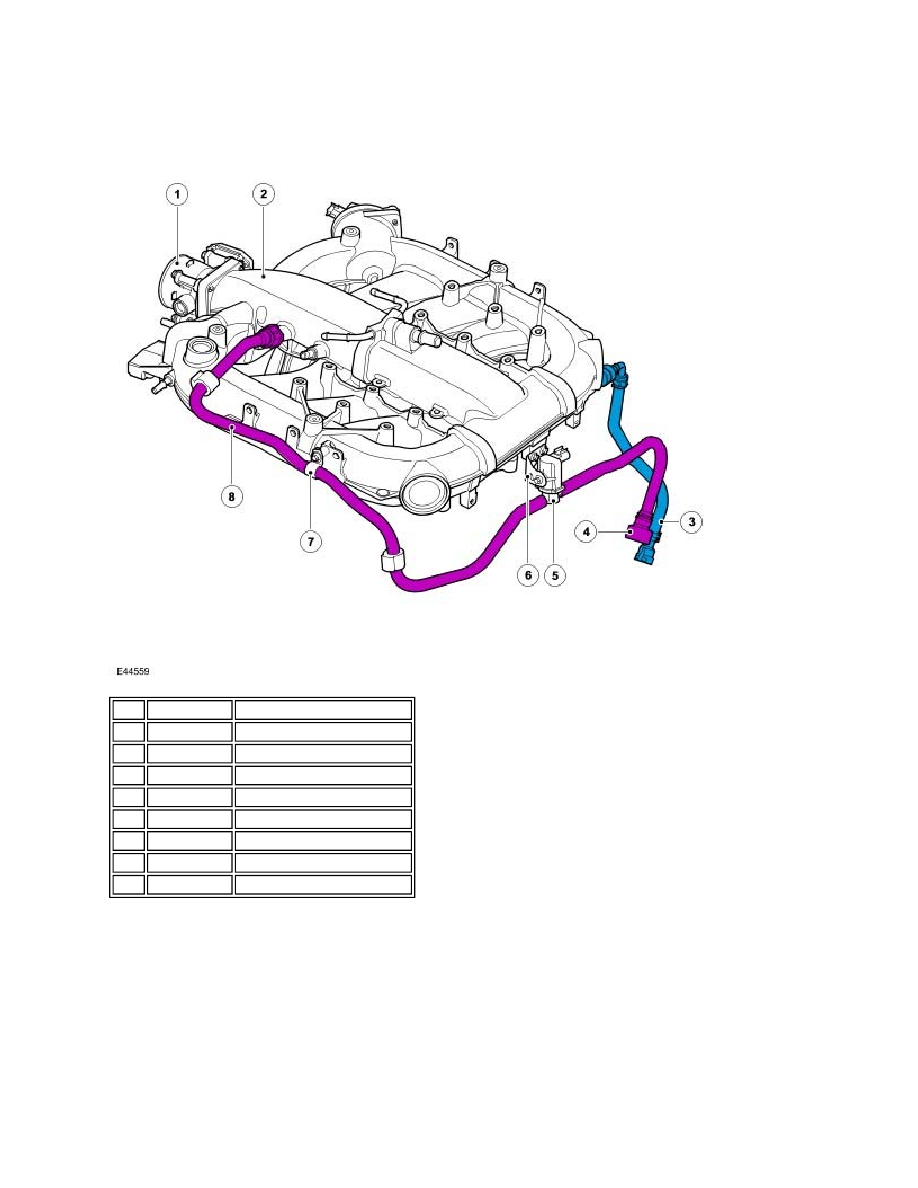

Item Part Number

Description

1

-

Electric throttle

2

-

Air intake manifold

3

-

Fuel feed jump hose

4

-

Purge hose connector

5

-

Purge valve

6

-

Purge valve bracket

7

-

Hose clamp

8

-

Manifold to purge valve hose