LR3/Disco 3

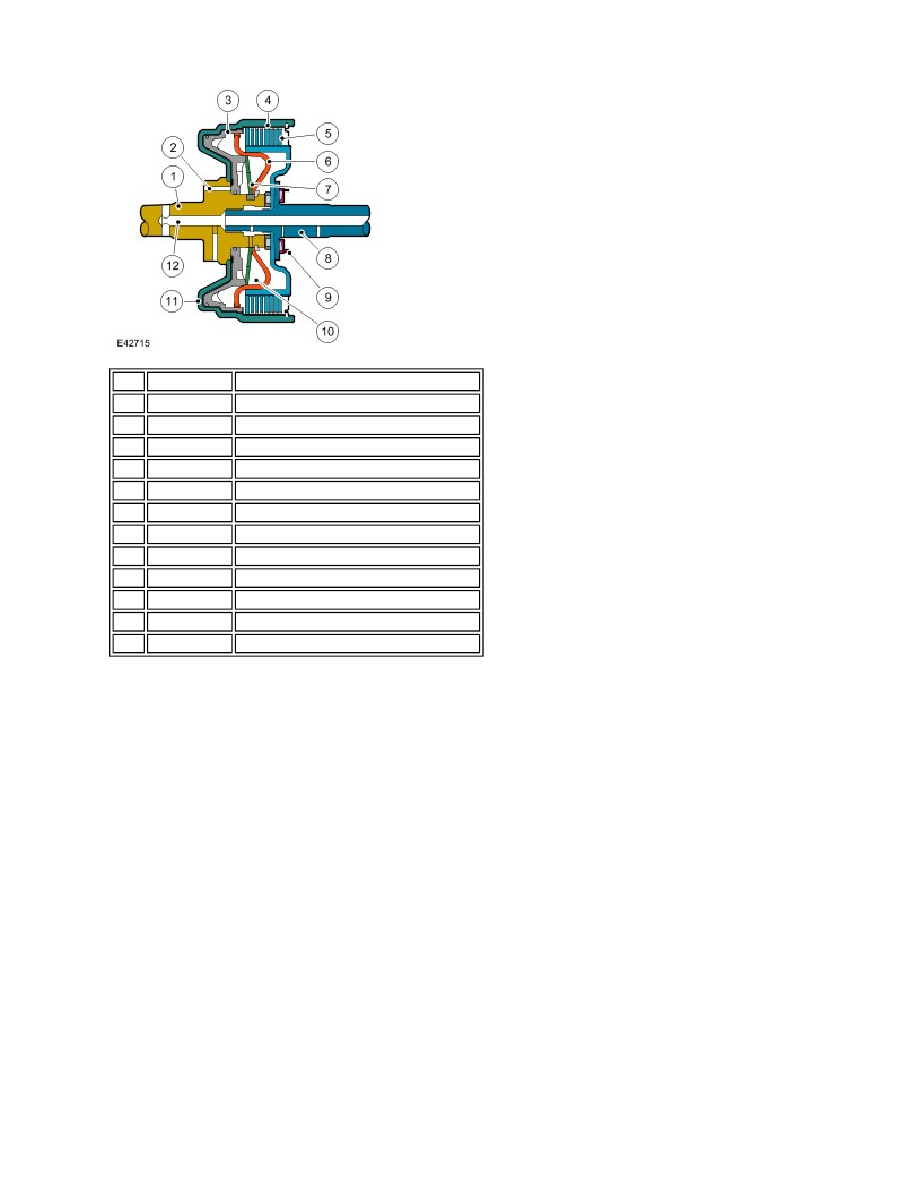

There are three drive clutches and two brake clutches used in the 6HP26 transmission. Each clutch comprises one or

more friction plates dependent on the output controlled. A typical clutch consists of a number of steel outer plates and

inner plates with friction material bonded to each face.

The clutch plates are held apart mechanically by a diaphragm spring and hydraulically by dynamic pressure. The pressure

is derived from a lubrication channel which supplies fluid to the bearings etc. The fluid is passed via a drilling in the output

shaft into the chamber between the baffle plate and the piston. To prevent inadvertent clutch application due to pressure

build up produced by centrifugal force, the fluid in the dynamic pressure equalisation chamber overcomes any pressure in

the piston chamber and holds the piston off the clutch plate assembly.

When clutch application is required, main pressure from the fluid pump is applied to the piston chamber from the supply

port. This main pressure overcomes the low pressure fluid present in the dynamic pressure equalisation chamber. The

piston moves, against the pressure applied by the diaphragm spring, and compresses the clutch plate assembly. When

the main pressure falls, the diaphragm spring pushes the piston away from the clutch plate assembly, disengaging the

clutch.

PLANETARY GEAR TRAINS

The planetary gear trains used on the 6HP26 transmission comprise a single web planetary gear train and a double web

planetary gear train. These gear trains are known as Lepelletier type gear trains and together produce the six forward

gears and the one reverse gear.

Single Web Planetary Gear Train

The single web planetary gear train comprises:

Item Part Number

Description

1

-

Input shaft

2

-

Main pressure supply port

3

-

Piston

4

-

Cylinder – External plate carrier

5

-

Clutch plate assembly

6

-

Baffle plate

7

-

Diaphragm spring

8

-

Output shaft

9

-

Bearing

10

-

Dynamic pressure equalisation chamber

11

-

Piston chamber

12

-

Lubrication channel