LR3/Disco 3

Alignment jig

Universal measuring system

Jig system

Ruler or tape measure

Any attached body parts that require accurate alignment and fitting must be incorporated in this step; for instance

bumpers, seals, headlamps, rear lamps and lock assembly components. If this is not done carefully it may result in

water leaks, wind noises and substantial follow-on work.

Ensure that edges line up with adjacent parts and check that gaps are consistent (compare left and right-hand

sides). Make sure that the shape of the vehicle is retained.

Secure the new part

NOTE :

Depending on accessibility the following methods for securing are available: Grip pliers (set of) Screw clamp (set

of) Self-tapping screws Tack welds

Grip pliers (set of)

Screw clamp (set of)

Self-tapping screws

Tack welds

Using a suitable tool ensure that the edges of sectional replacements of profiled parts line up. The edge is then

tack welded to ensure that it lines up.

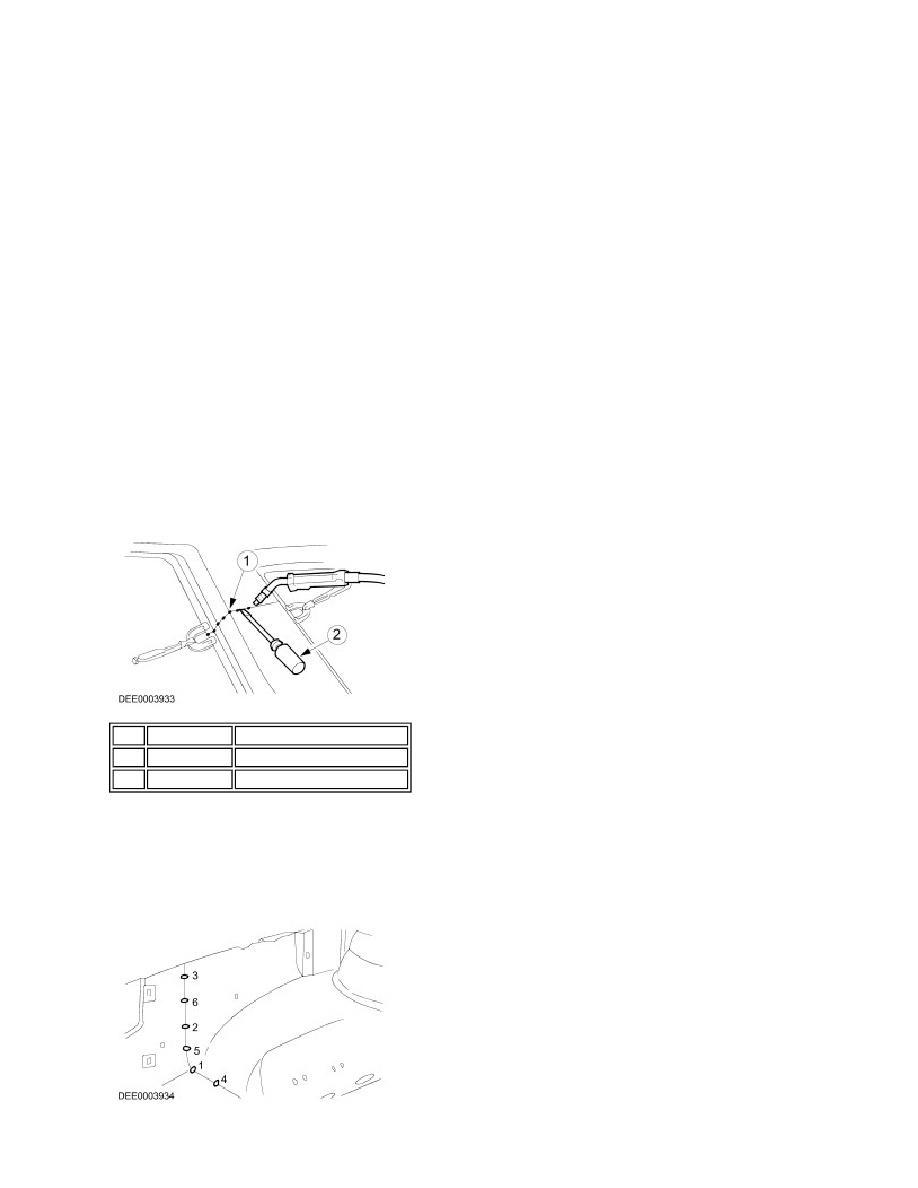

Aligning and tack weld

Longer joins are usually tack welded to prevent the panel from warping. It is important to carry out the tack welds

in the correct sequence (see diagram).

Weld in the new part following the instructions in the repair manual.

Correct tack welding sequence

The need for subsequent follow-on work can be significantly reduced if aligning and tack-welding are

carried out with due care.

Item Part Number

Description

1

Tack welds

2

Using a suitable tool to align