LR3/Disco 3

l

Remove all traces of locking agent from the threads.

l

Ensure that threads are clean and free from oil or grease.

l

Apply the specified locking agent to the bolt threads.

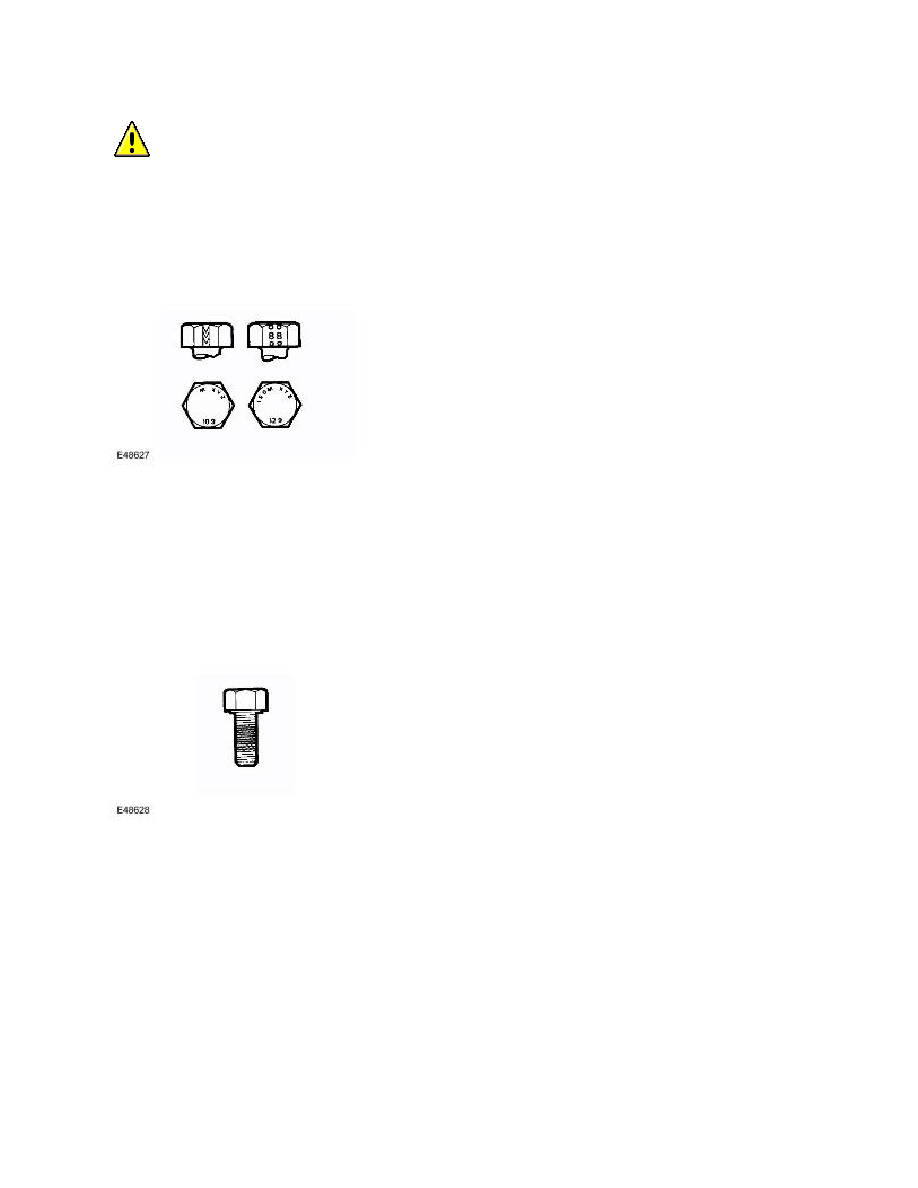

Bolt and Nut Identification

An ISO metric bolt or screw made of steel and larger than 6 mm in diameter can be identified by either of the symbols ISO

M or M embossed or indented on top of the bolt head.

In addition to marks identifying the manufacturer, the top of the bolt head is also marked with symbols indicating the

strength grade e.g. 8.8, 10.9, 12.9, 14.9. Alternatively, some bolts and screws have the M and strength grade symbol

stamped on the flats of the hexagon.

Encapsulated ('Patched') bolts and screws

Encapsulated ('patched') bolts and screws have a thread locking agent applied to the threads during manufacture. Most

thread locking agents are colored, the band of color extending for 360 ° around the thread. Some locking agents however,

are neutral in color and may not be so easily identified apart from a slightly darker area of thread where the locking agent

has been applied. The locking agent is released and activated by the tightening process and is then chemically cured to

provide the locking action.

Self-locking bolts and screws

CAUTION: DO NOT use a wire brush; take care that threads are not damaged.