LT230 Transfer Box Differential Overhaul - Page 65

TRANSFER BOX

OVERHAUL

27

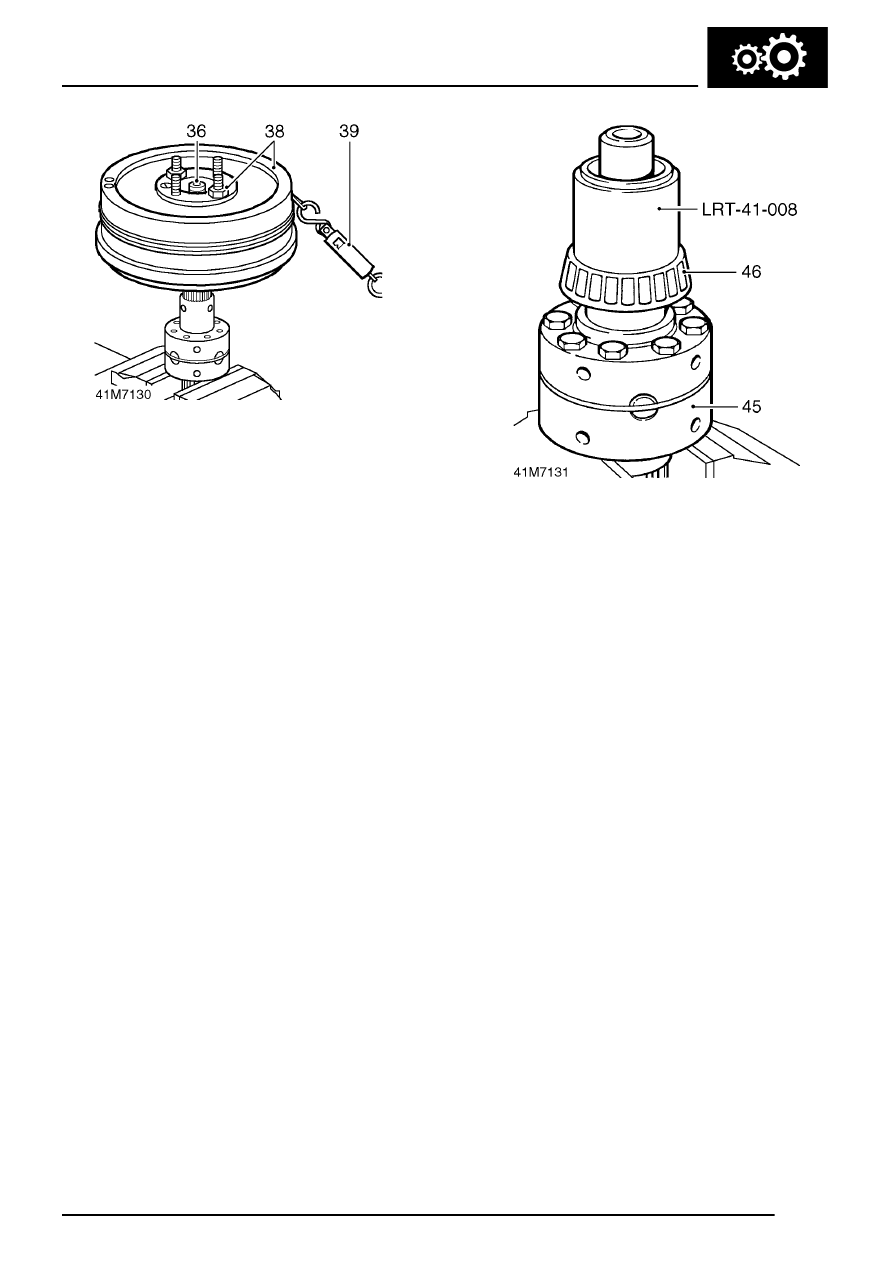

36. Invert assembly in vice and then insert rear

output shaft into rear half carrier, check that

gears rotate freely.

37. Fit output flange on to splines of output shaft,

do not fit flange nut at this stage.

38. Fit transmission brake drum to output flange,

secure with 2 nuts.

39. Carry out load to turn check using same

method as for front half carrier.

40. When load to turn figure is correct, record final

figure.

41. Upon completion, fit sun gear and selected

thrust washer to front half carrier.

42. Fit front half carrier ensuring that alignment

marks are together.

43. Fit bolts and tighten by diagonal selection to 60

Nm (44 lbf.ft).

44. With differential assembled, fit rear output shaft

and brake drum and check overall load to turn.

This should be approximately equal to total

load to turn figure of both front and rear half

carriers added together:

Used gears = 0.90 kg (2.0 lb)

New gears = 3.44 kg (7.6 lb)

45. Secure rear half carrier in a soft-jawed vice.

46. Fit a new front bearing using tool LRT-41-008.