Range Rover P38

19

FUEL SYSTEM

NEW RANGE ROVER

40

DESCRIPTION AND OPERATION

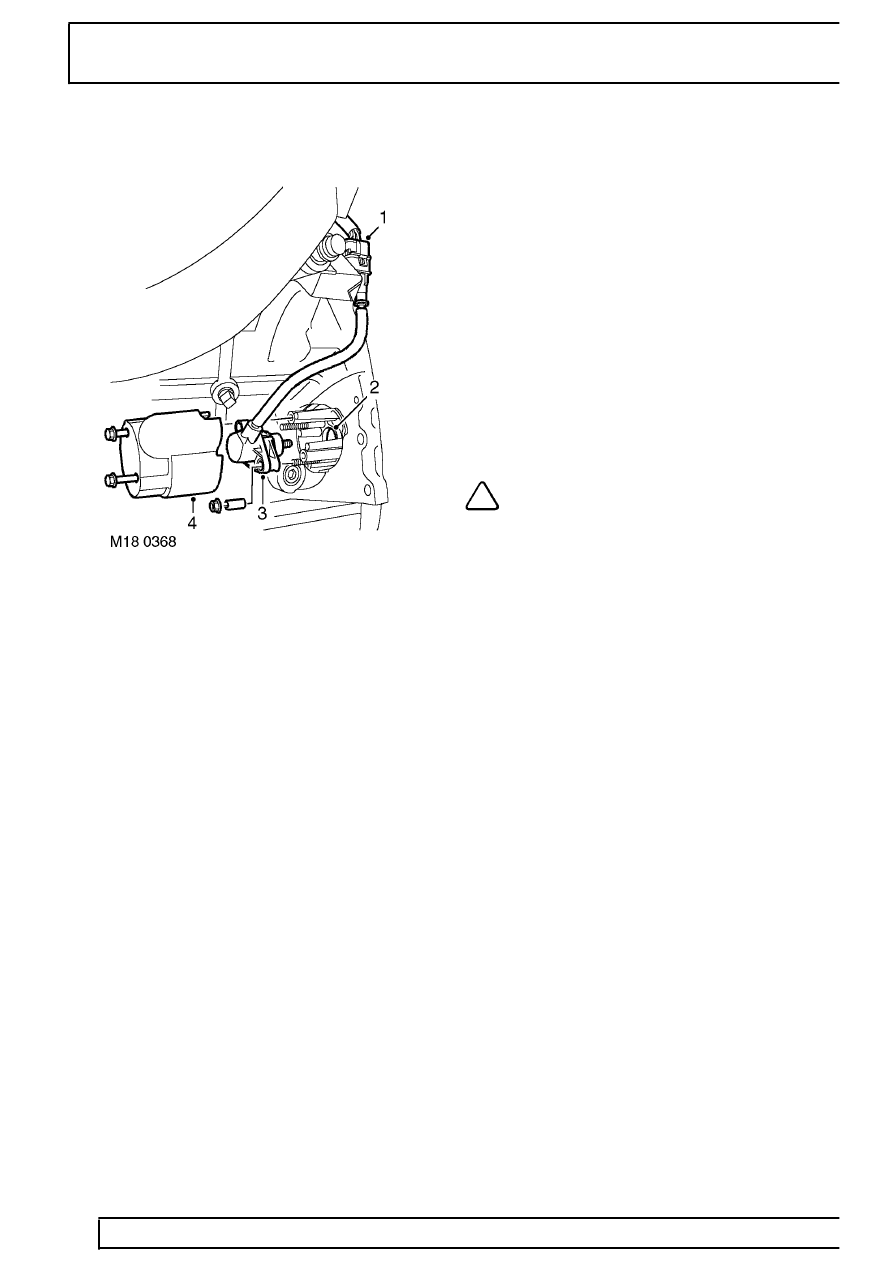

Crankshaft speed and position (CKP) sensor -

(from 99MY)

1. Multiplug

2. Aperture to reluctor ring

3. CKP sensor

4. Heatshield

The CKP sensor is located at the lower, rear LH side

of the engine below cylinder number 7. The CKP

sensor is protected by a heatshield which is attached

to the rear flange of the engine block by two M5 bolts.

The CKP sensor itself is located on two studs and

fixed in position by two M5 nuts and 18mm spacers.

The sensor has a flying lead which terminates in a

3-pin multiplug that connects to the engine harness

and is mounted to a bracket to the rear of the left hand

cylinder head.

The tip of the CKP sensor protrudes through an

aperture in the engine block rear flange, adjacent to

the outer circumference of the flywheel. A 60-tooth

reluctor ring is included on the flywheel which

provides the reference signal to the crankshaft

position sensor.

The ECM uses the signal produced at the CKP sensor

to determine the position of the crankshaft to enable

accurate ignition and fuel injection timing. The ECM

also determines the engine speed at any particular

instance through analysis of the frequency of

fluctuations induced in the CKP sensor as the teeth of

the reluctor ring pass by the sensor tip.

The CKP sensor is a variable reluctance sensor, and

contains a permanent magnet and soft iron core

surrounded by a copper winding. As the reluctor ring

passes by the sensor tip it causes a voltage to be

induced in the sensor, consequently the CKP sensor

does not need a power supply for operation. The

signal wires of the CKP sensor are surrounded by a

grounded screen to prevent noise being induced in

the signal wires and causing a spurious interference

signal being passed to the ECM.

NOTE: When fitting a CKP sensor, ensure

no ferrous metal has been attracted to it

by its magnet. Ensure the sensor pin is

straight and undamaged.

The reluctor ring teeth are spaced at 6

°

intervals and

are 3

°

wide. Two of the reluctor ring teeth are

removed, to provide a reference mark which indicates

when the crankshaft is at 60

°

BTDC for number 1

cylinder. The remaining 58 teeth cause an AC voltage

to be induced in the sensor pick-up, with the

amplitude of the signal increasing with rising engine

speed. The voltage generated is an analogue signal

capable of peak amplitude voltages of up to 300V.

The distance of the tip from the top of the reluctor ring

teeth is important as the amplitude of the detected

signal will be reduced in proportion to an increase in

the gap between the sensor tip and the top of the

reluctor ring teeth. If the air gap becomes too wide,

the CKP signal could become too weak and possible

misfires could occur. Spacers are included in the CKP

sensor kit which are used to ensure the correct gap

between the sensor tip and reluctor ring teeth.

The ECM uses the falling edge of the signal waveform

as its reference for each reluctor ring tooth.

Consequently, if the input signal wire and reference

ground wire are inadvertently reversed, the ECM will

react by providing a 3

°

advance in ignition timing.